Measuring device for mechanical-electrical-hydraulic coupling vertical vibration of screw-down system of rolling mill

A technology of a pressing system and a measuring device, which is applied in the direction of length measuring device, safety equipment of rolls, metal rolling, etc., to achieve the effect of accelerating wear speed, ensuring safe operation, important engineering value and economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

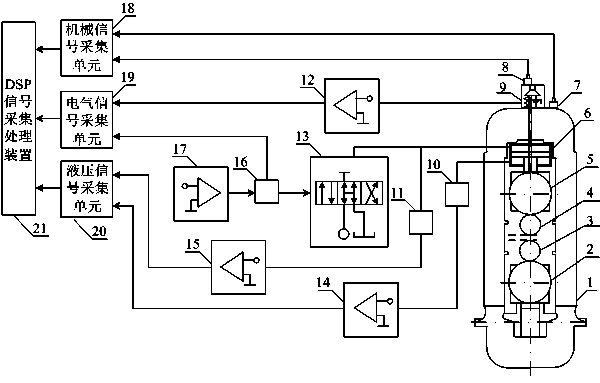

[0015] Attached below figure 1 A further description will be made on the measuring device of the electromechanical-hydraulic coupling vertical vibration of the rolling mill reduction system of the present invention.

[0016] According to attached figure 1 Fix the shell of the position sensor 9 on the top of the rolling mill stand 1, the position sensor 9 moves together with the piston in the hydraulic cylinder 6 and converts the detected displacement signal of the piston into a current of 4~20mA through the position transmitter 12 The signal is transmitted to the electrical signal acquisition unit 19, and the position sensor housing vertical vibration acceleration sensor 8 is installed on the housing top of the position sensor 9, and is used to transmit the vibration signal of the measured position sensor 9 housing to the mechanical signal acquisition unit 18. The stand vertical vibration acceleration sensor 7 is installed on the top of the rolling mill stand 1, and is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com