Laser-tig composite wire sealing welding method for L-shaped aluminum alloy structure

A sealing welding and aluminum alloy technology, which is applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., to achieve the effect of ensuring sealing welding efficiency, reducing the range of heat-affected zone, and reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

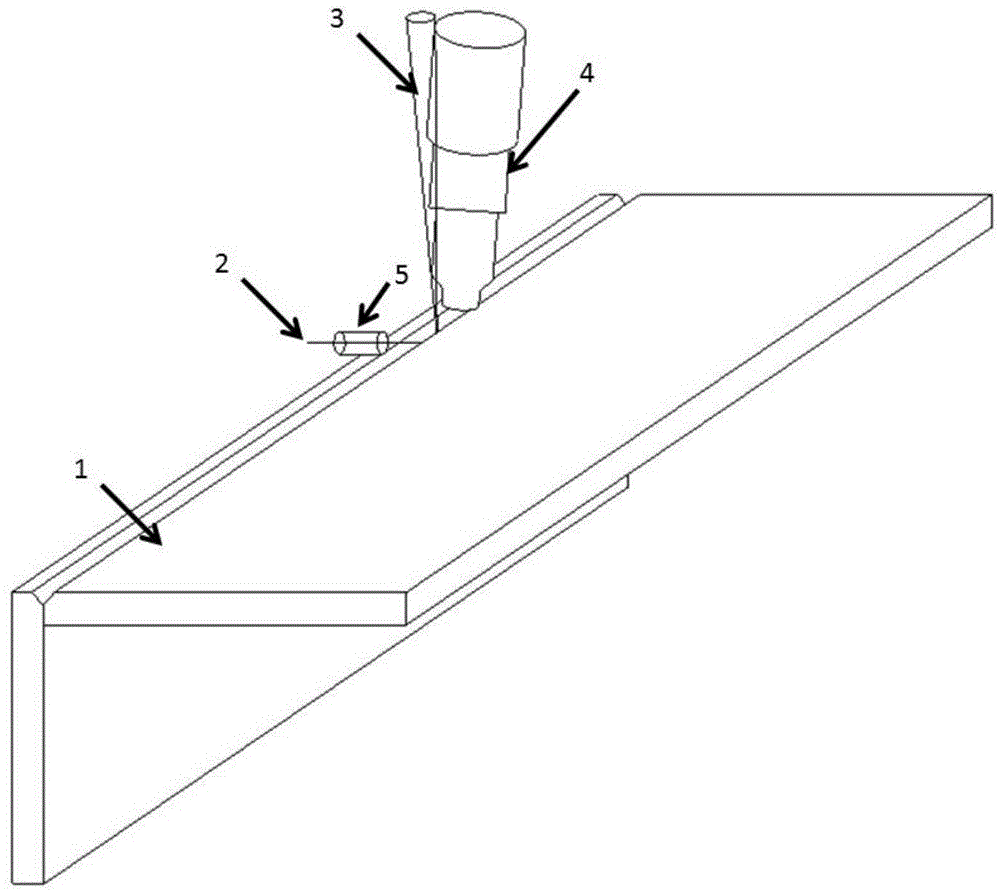

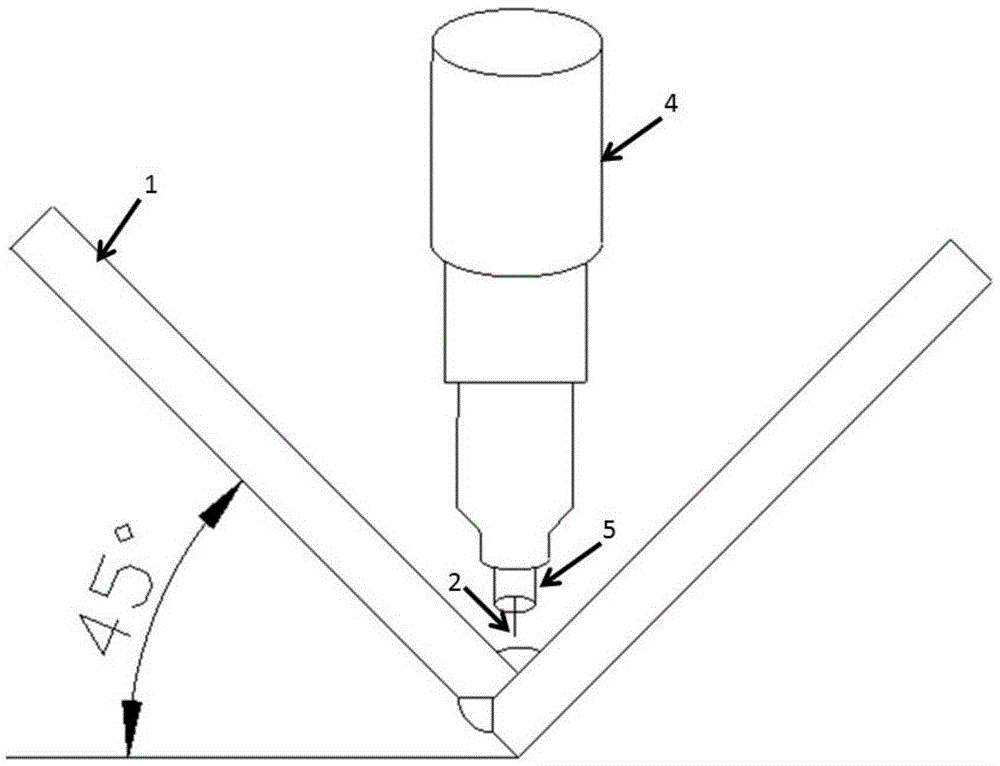

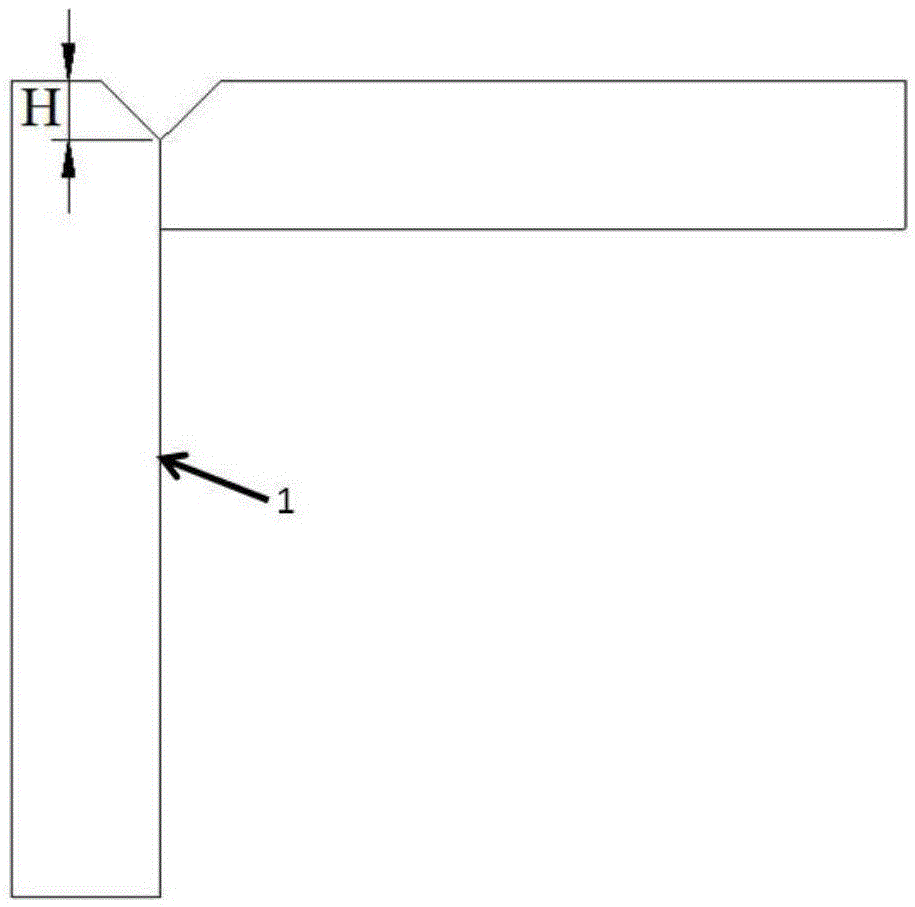

[0022] Example 1: Taking the 10mm thick 6061 aluminum alloy 1 as an example, the 10mm thick 6061 aluminum alloy 1 is butted according to the L-shaped structure without gaps before welding, and then a V-shaped groove is made on the outside of the formed L-shaped structure, and the depth of the V-shaped groove is 3mm, unilateral angle 43°; adjust the relative positions of laser 3, TIG welding torch 4 and wire feeding nozzle 5 to realize simultaneous lifting of laser, TIG welding torch and wire feeding nozzle; the diameter of welding wire 2 used is 1.2mm.

[0023] First, weld the outer side of the L-shaped aluminum alloy 1 structure, place the outer side of the L-shaped aluminum alloy 1 structure horizontally, and fill the welding process parameters of the first layer of welding with laser line energy density of 70J / mm and TIG current line energy density of 360J / mm. The interlayer temperature is 290°C, the laser defocus amount is -0.9mm; the welding process parameters of the secon...

Embodiment 2

[0025] Example 2: Taking the 15mm thick 6061 aluminum alloy 1 as an example, the 15mm thick 6061 aluminum alloy 1 is butted according to the L-shaped structure without gaps before welding, and then a V-shaped groove is made on the outside of the structure, the depth of the V-shaped groove is 4mm, and one side The angle is 45°; adjust the relative positions of laser 3, TIG welding torch 4 and wire feeding nozzle 5 to realize simultaneous lifting of laser 3, TIG welding torch 4 and wire feeding nozzle 5; the diameter of welding wire 2 used is 1.2mm.

[0026] First, weld the outer side of the L-shaped aluminum alloy 1 structure, place the outer side of the L-shaped aluminum alloy 1 structure horizontally, and fill the welding process parameters of the first layer of welding with laser line energy density of 70J / mm and TIG current line energy density of 360J / mm. The interlayer temperature is 290°C, the laser defocus amount is -1mm; the welding process parameters of the second layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com