Method for carrying out processing treatment on bamboo chopsticks via ozone

A technology of ozone and bamboo chopsticks, applied in wood processing equipment, reed/straw processing, manufacturing tools, etc., can solve problems such as human health damage, and achieve energy saving and good anti-mold effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

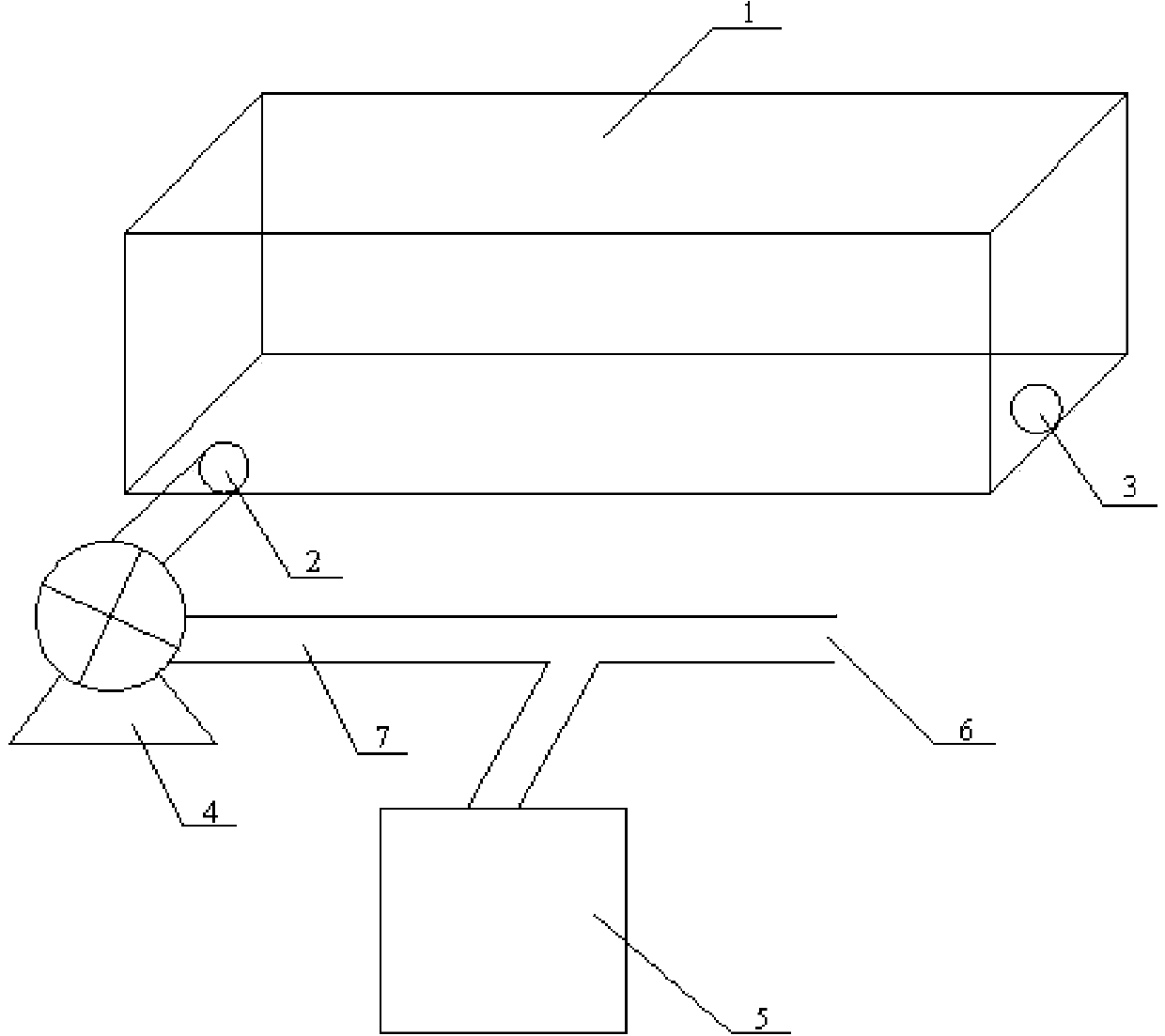

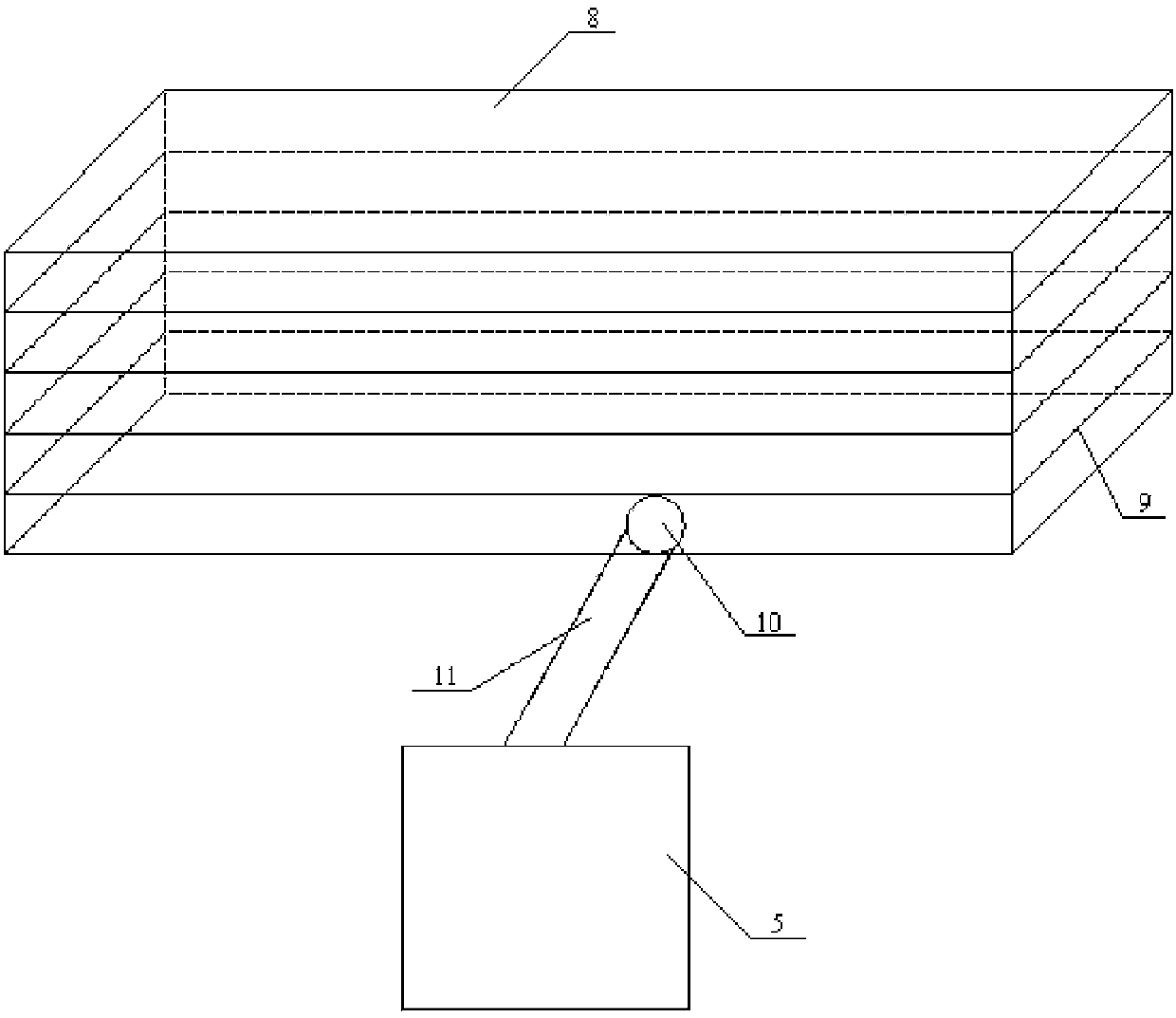

Method used

Image

Examples

Embodiment 1

[0023] Step (1): wet disinfection, bleaching. Put the bamboo chopsticks made of bamboo into the steel wet reaction tank after being ground and finely processed. In the water tank, adjust the power of the ozone generator to produce 10g h of ozone -1 , when the height of the water in the tank is close to the height of the tank, stop water injection and pass ozone. The ozone in the water decomposes slowly by itself, and the bamboo chopsticks are immersed in the water tank for 7 hours. During the whole process, the product of the ozone concentration and time in the water is kept at 100mg·h / L.

[0024] Step (2): dry mildew prevention. Put the bamboo chopsticks soaked in step (1) into a ventilated room to air-dry, then put them into a dry aeration tank, turn on the ozone generator and let the ozone flow in for 0.5 hours. During the whole ozone passing process, the total amount of ozone produced The mass ratio to the total amount of chopsticks is 1:20000, and the chopsticks can be...

Embodiment 2

[0028] Step (1): wet disinfection, bleaching. Put the bamboo chopsticks made of bamboo into the steel wet reaction tank after being ground and finely processed. In the water tank, adjust the power of the ozone generator to produce 20g h of ozone -1 , when the height of the water in the tank is close to the height of the tank, stop water injection and pass ozone. The ozone in the water slowly decomposes by itself, and the bamboo chopsticks are soaked in the water tank for 9 hours. During the whole process, the product of the ozone concentration and time in the water is kept at 180mg·h / L.

[0029] Step (2): dry mildew prevention. Put the bamboo chopsticks soaked in the step (1) into a ventilated room to air-dry, then put into a dry aeration tank, open the ozone generator and let the ozone flow in for about 1 hour. The mass ratio of the amount to the total amount of chopsticks is 1:15000, and the chopsticks can be sold after finishing the ozone process.

[0030] Finally, the ...

Embodiment 3

[0033] Step (1): wet disinfection, bleaching. Put the bamboo chopsticks made of bamboo into the steel wet reaction tank after being ground and finely processed. In the water tank, adjust the power of the ozone generator to produce 50g·h of ozone -1 , when the height of the water in the tank is close to the height of the tank, stop water injection and pass ozone. The ozone in the water slowly decomposes by itself, and the bamboo chopsticks are immersed in the water tank for 6 hours. During the whole process, the product of the ozone concentration and time in the water is kept at 200mg·h / L.

[0034] Step (2): dry mildew prevention. Put the bamboo chopsticks soaked in step (1) into a ventilated room to air-dry, then put them into a dry aeration tank, turn on the ozone generator and let the ozone flow in for 1 hour. During the whole process of passing through the ozone, the total amount of ozone generated The mass ratio to the total amount of chopsticks is 1:15000, and the chop...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap