Process method and device for advanced treatment of coking biochemical wastewater by using coke powder

A technology of advanced treatment and process method, applied in chemical instruments and methods, multi-stage treatment of water/sewage, water/sludge/sewage treatment, etc. To achieve the effect of obvious filtering effect, strong adsorption capacity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking the treatment of wastewater in the coking production process of a coking plant as an example, the coking plant discharges about 100 tons of wastewater per hour. After testing, the COD of the wastewater is 386mg / L, and the volatile phenol is 0.96mg / L. According to the initial COD and volatile phenol values of the wastewater and the hourly discharge, it is determined to build 3 premixing tanks and inclined plate sedimentation tanks, and the treatment capacity of each inclined plate sedimentation tank is 100t / hour.

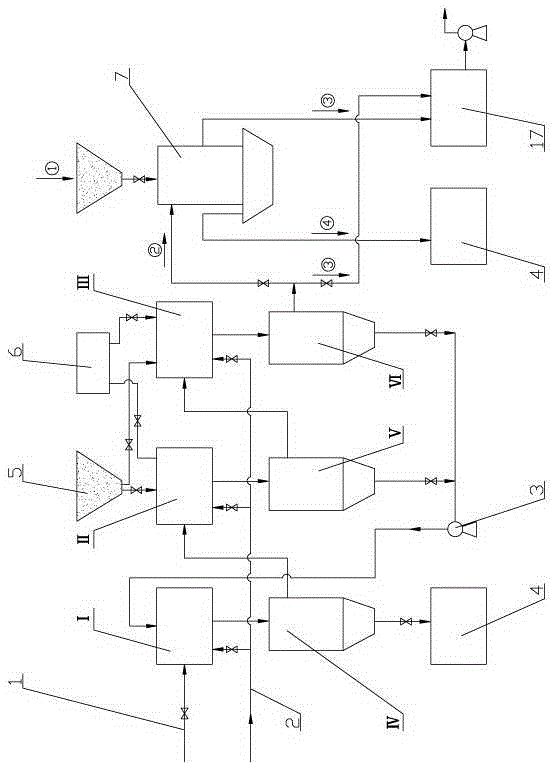

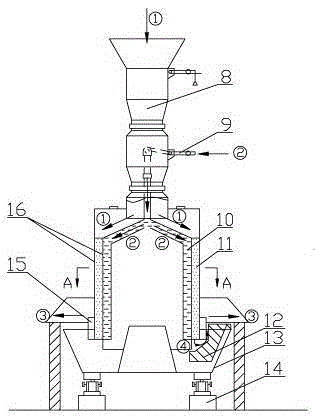

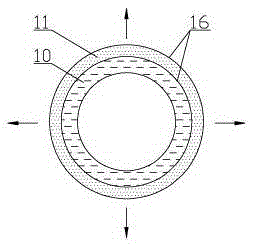

[0035] The specific processing steps are as follows: see figure 1 As shown in , three premixing tanks are set up, namely No. 1 premixing tank I, No. 2 premixing tank II and No. 3 premixing tank III, and the lower part of each premixing tank is respectively equipped with No. 1 inclined plate sedimentation tank IV , No. 2 inclined plate sedimentation tank V and No. 3 inclined plate sedimentation tank VI; the outlet pipe at the bottom of each premixing t...

Embodiment 2

[0039] Take the treatment of coking wastewater in the coking production process of a coking plant as an example. The coking plant discharges about 100 tons of wastewater per hour. Due to the unstable production process, the COD of the wastewater is 430mg / L and the volatile phenol is 1.6mg / L. According to the initial COD and volatile phenol values of the wastewater and the hourly discharge, the 3 premixing tanks and inclined plate sedimentation tanks used in Example 1 are still used, and the treatment capacity of each inclined plate sedimentation tank is 100t / hour.

[0040] The specific treatment process is the same as in Example 1, but the wastewater is treated through the above-mentioned 3-stage premixing tank and inclined plate sedimentation tank. After testing, the COD of the effluent is 98 mg / L, and the volatile phenol is 0.43 mg / L, which does not meet the requirements of GB16171-2012. , at this time, it is necessary to enable the standpipe type automatic feeding and disc...

Embodiment 3

[0042] Taking the treatment of coking wastewater in the coking production process of a coking plant as an example, the coking plant discharges about 100 tons of wastewater per hour. After testing, the COD of the wastewater is 356mg / L, and the volatile phenol is 0.92mg / L. According to the initial COD and volatile phenol values of the wastewater and the hourly discharge, it is determined to build 3 premixing tanks and inclined plate sedimentation tanks, and the treatment capacity of each inclined plate sedimentation tank is 100t / hour.

[0043] The specific treatment process is the same as in Example 1. The wastewater in this example is treated through the above-mentioned 3-stage premixing tank and inclined plate sedimentation tank. After testing, the COD of the effluent is 63 mg / L, and the volatile phenol is 0.15 mg / L, which is in line with GB16171- According to the regulations in 2012, it can be directly discharged or converted to industrial water. In this embodiment, the set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com