Preparation method of cement graded broken stones for high-speed rail roadbeds

A technology of graded crushed stone and high-speed railway foundation is applied in the field of preparation of cement-graded crushed stone for high-speed railway foundation, which can solve the problems that the deflection index cannot characterize the durability, crack resistance, water stability, and lack of rationality of the roadbed structure. , to achieve the effect of improved mechanical properties, good effect, good impermeability and frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: The raw materials were weighed according to the mass fraction, and the mass ratio of graded crushed stone, label P·II52.5 cement, and tap water was 90:5:5. Fully mixed and compacted, the curing temperature is 20±2°C, and the curing humidity is above 90%; the compressive strength at 7 days is 5.9MPa, the compressive strength at 28 days is 10.5MPa, and the dry density is 2.28g / cm 3 , Shrinkage coefficient 0.35.

Embodiment 2

[0022] Example 2: The raw materials were weighed according to the mass fraction, and the mass ratio of graded crushed stone, P·II52.5 cement, and tap water was 85:7:7. After fully mixing and compacting, the curing temperature is 20±2°C, and the curing humidity is above 90%; the 7d compressive strength is 7.5MPa, the 28d compressive strength is 101.1MPa, and the dry density is 2.31g / cm 3 , Shrinkage coefficient 0.63.

Embodiment 3

[0023] Example 3: The raw materials were weighed according to the mass fraction, and the mass ratio of graded crushed stone, P·II52.5 cement, and tap water was 95:3:6. Fully mixed and compacted, curing temperature is 20±2°C, curing humidity is above 90%; 7d compressive strength is 5.2MPa, 28d compressive strength is 9.4MPa, dry density is 2.25g / cm 3 , Shrinkage coefficient 0.29.

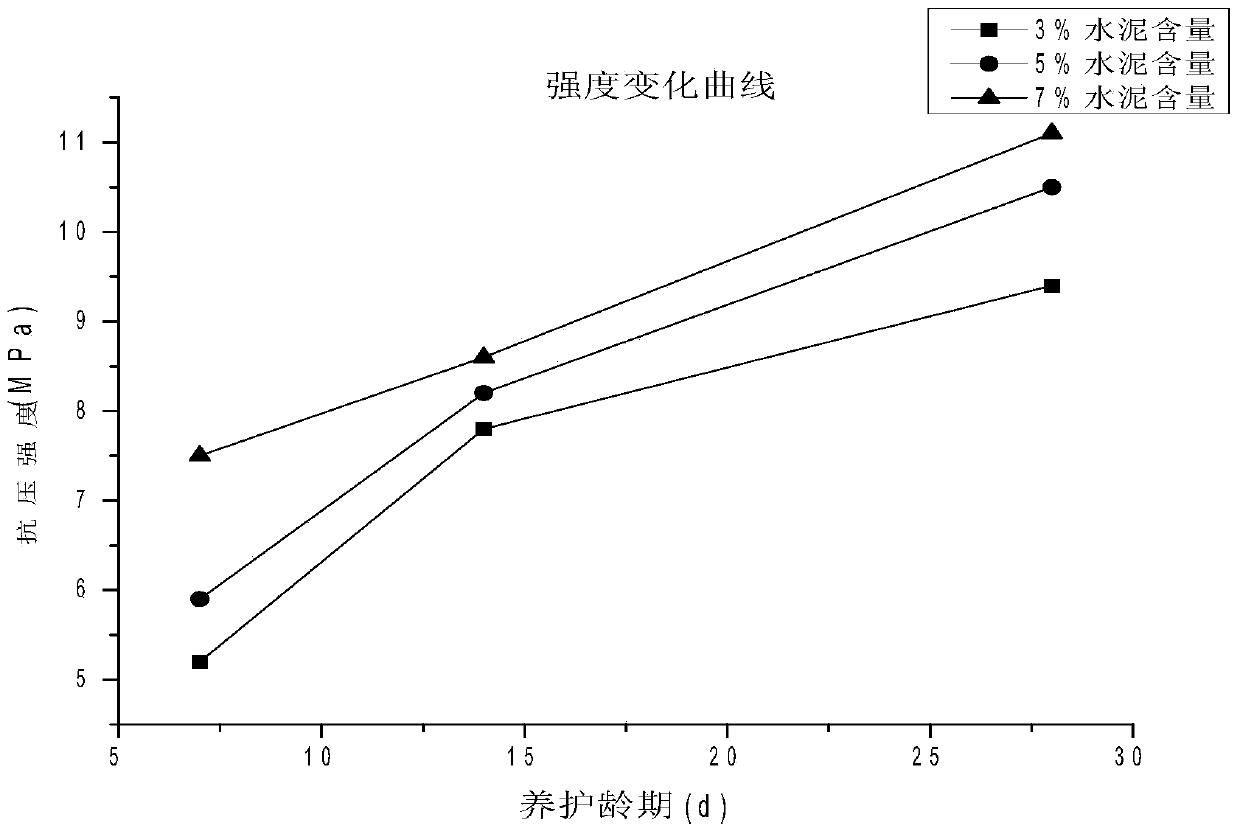

[0024] The change law of compressive strength of cement graded crushed stone with different cement content with age is shown in figure 1 , it can be seen from the figure that the early strength of cement-stabilized macadam increases rapidly with age, and will gradually ease after reaching a certain curing age, and the more cement content, the higher the compressive strength.

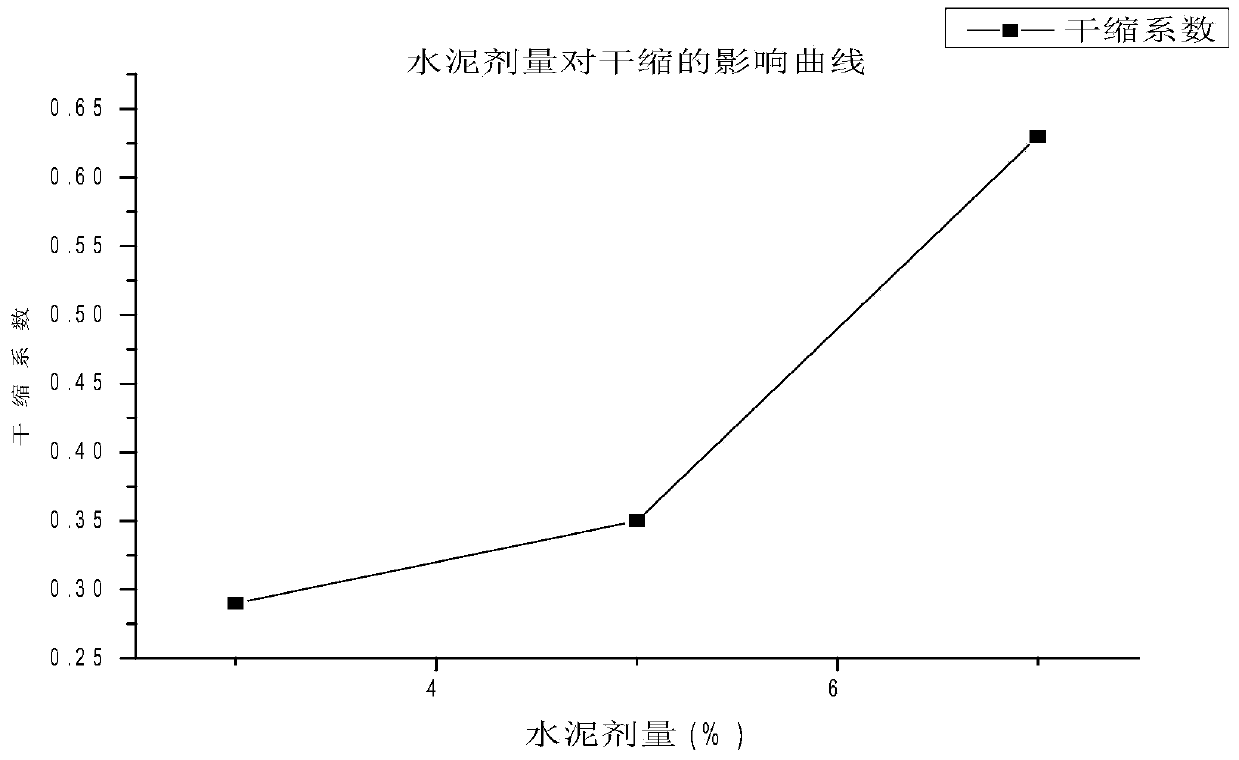

[0025] The effect of cement dosage on the drying shrinkage performance of cement graded crushed stone is shown in figure 2 , it can be seen from the figure that as the cement dosage increases, the shrinkage strain and shrink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com