Preparation method of green glaze of Ru porcelain

A technology of celadon and Ru porcelain, applied in the field of preparation of Ru porcelain celadon, can solve the problems of complex colloidal mineral composition and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

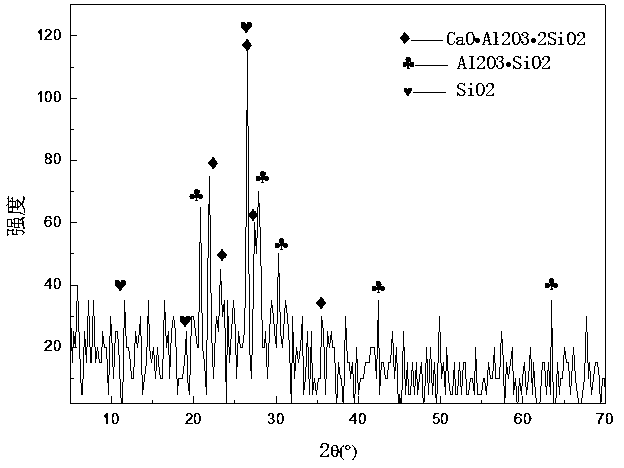

Image

Examples

Embodiment 1

[0015] According to the following ratio, the raw materials are mixed and ball-milled and passed through a 250-mesh sieve, and the sieve residue is 0.2%, and glazed on the body after biscuit firing. Before 980°C, use an oxidizing atmosphere, and use a reducing atmosphere above 980°C to raise the temperature to the highest temperature. Heat at 1280°C for 10 minutes, cool to 1120°C and hold for 0.5h, then rapidly cool to 950°C and then slowly cool to room temperature.

[0016] The glaze ratio is:

[0017] Yaoli glaze fruit 28%, purple sandstone 10%, fly ash 10%, white agate 12%, calcined kaolin 19%, dolomite 3%, calcite 4%, feldspar 14%.

[0018] The glaze n(SiO 2 ) / n(Al 2 o 3 ) molar ratio=5.54, n(CaO) / n(MgO) molar ratio=6.18, Fe 2 o 3 Molecular weight = 0.021, the color of the glaze is light blue, and the color of the glaze is lighter.

Embodiment 2

[0020] According to the following raw material ratio, the raw materials are mixed and ball milled and passed through a 250-mesh sieve. The sieve residue is 0.2%. Glaze the green body after biscuit firing. Before 980°C, use an oxidizing atmosphere, and use a reducing atmosphere above 980°C to rise to the highest level. After the temperature point is 1250°C, keep warm for 10 minutes, cool down to 1130°C and keep warm for 0.5h, then rapidly cool to 950°C, and then slowly cool.

[0021] The glaze ratio is:

[0022] Yaoli glaze fruit 20%, purple sandstone 10%, fly ash 7%, white agate 15%, calcined kaolin 14%, dolomite 8%, calcite 6%, feldspar 20%.

[0023] The glaze n(SiO 2 ) / n(Al 2 o 3 ) molar ratio=6.46, n(CaO) / n(MgO) molar ratio=3.35, Fe 2 o 3 The number of moles=0.016, the cyan color of the glaze tone is slightly lighter than that of Example 1, and the blue accentuates.

Embodiment 3

[0025] According to the following raw material ratio, the raw materials are mixed and ball milled and passed through a 250-mesh sieve. The sieve residue is 0.2%. Glaze the green body after biscuit firing. Before 980°C, use an oxidizing atmosphere, and use a reducing atmosphere above 980°C to rise to the highest level. After the temperature point is 1270°C, keep warm for 10 minutes, cool down to 1150°C and keep warm for 0.5h, then rapidly cool to 950°C, and then slowly cool.

[0026] The glaze ratio is:

[0027] Yaoli glaze fruit 35%, purple sandstone 15%, fly ash 12%, white agate 8%, calcined kaolin 12%, dolomite 4%, calcite 2%, feldspar 12%.

[0028] The glaze n(SiO 2 ) / n(Al 2 o 3 ) molar ratio=5.78, n(CaO) / n(MgO) molar ratio=5.32, Fe 2 o 3 The number of moles=0.027, the glaze tone is slightly darker than that of Example 2, and the lightness decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com