A method and system for vacuum distillation deamination of n,n-dimethyldecylamide

A technology of dimethyldecylamide and dimethylamine, which is applied in the field of N, can solve the problems of poor quality, yellowing of color, etc., and achieve the effect of low cost, good deamination effect, and reasonable and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

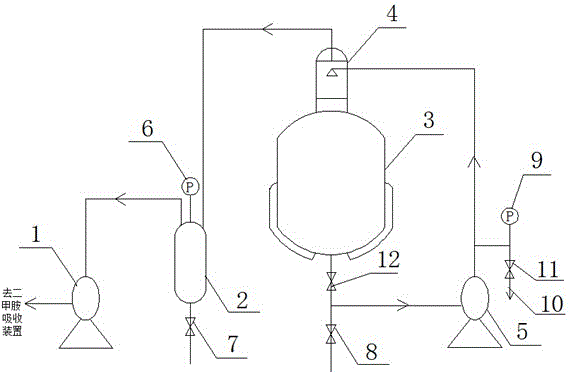

Image

Examples

Embodiment 1

[0023] Deamination of N,N-dimethyldecylamide product.

[0024] The N,N-dimethyldecylamide containing dimethylamine is sucked into the distillation still by a vacuum pump; under vacuum conditions, the circulating material pump is turned on to carry out vacuum distillation of the material in the still, and the distillation is carried out through a spray tower. The distillate of the still is sprayed and circulated, the vacuum distillation temperature is controlled at 50°C, and the vacuum degree is controlled at -0.09Mpa; the components distilled from the still are connected to a dimethylamine absorption device to absorb dimethylamine; sampling and analysis are performed until the sample No dimethylamine, cooled to normal temperature, and discharged to obtain N,N-dimethyldecylamide product without dimethylamine.

Embodiment 2

[0026] Deamination of N,N-dimethyldecylamide product.

[0027] The N,N-dimethyldecylamide containing dimethylamine is sucked into the distillation still by a vacuum pump; under vacuum conditions, the circulating material pump is turned on to carry out vacuum distillation of the material in the still, and the distillation is carried out through a spray tower. The distillate of the still is sprayed and circulated, the vacuum distillation temperature is controlled at 30°C, and the vacuum degree is controlled at -0.20Mpa; the components distilled from the still are connected to a dimethylamine absorption device to absorb dimethylamine; sampling and analysis are performed until the sample No dimethylamine, cooled to normal temperature, and discharged to obtain N,N-dimethyldecylamide product without dimethylamine.

Embodiment 3

[0029] Deamination of N,N-dimethyldecylamide product.

[0030] The N,N-dimethyldecylamide containing dimethylamine is sucked into the distillation still by a vacuum pump; under vacuum conditions, the circulating material pump is turned on to carry out vacuum distillation of the material in the still, and the distillation is carried out through a spray tower. The distillate of the still is sprayed and circulated, the vacuum distillation temperature is controlled at 40°C, and the vacuum degree is controlled at -0.10Mpa; the components distilled from the still are connected to a dimethylamine absorption device to absorb dimethylamine; sampling and analysis are performed until the sample No dimethylamine, cooled to normal temperature, and discharged to obtain N,N-dimethyldecylamide product without dimethylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com