Toning base paint for sand-wall multicolor coating, and sand-wall multicolor coating and preparation method thereof

A multi-color paint, sand-wall-shaped technology, applied in the field of sand-wall-shaped multi-color paint and sand-wall-shaped multi-color paint preparation, can solve the problems of complex production process, paint fading, poor stability of the paint system, etc., achieve simple production process, improve production efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

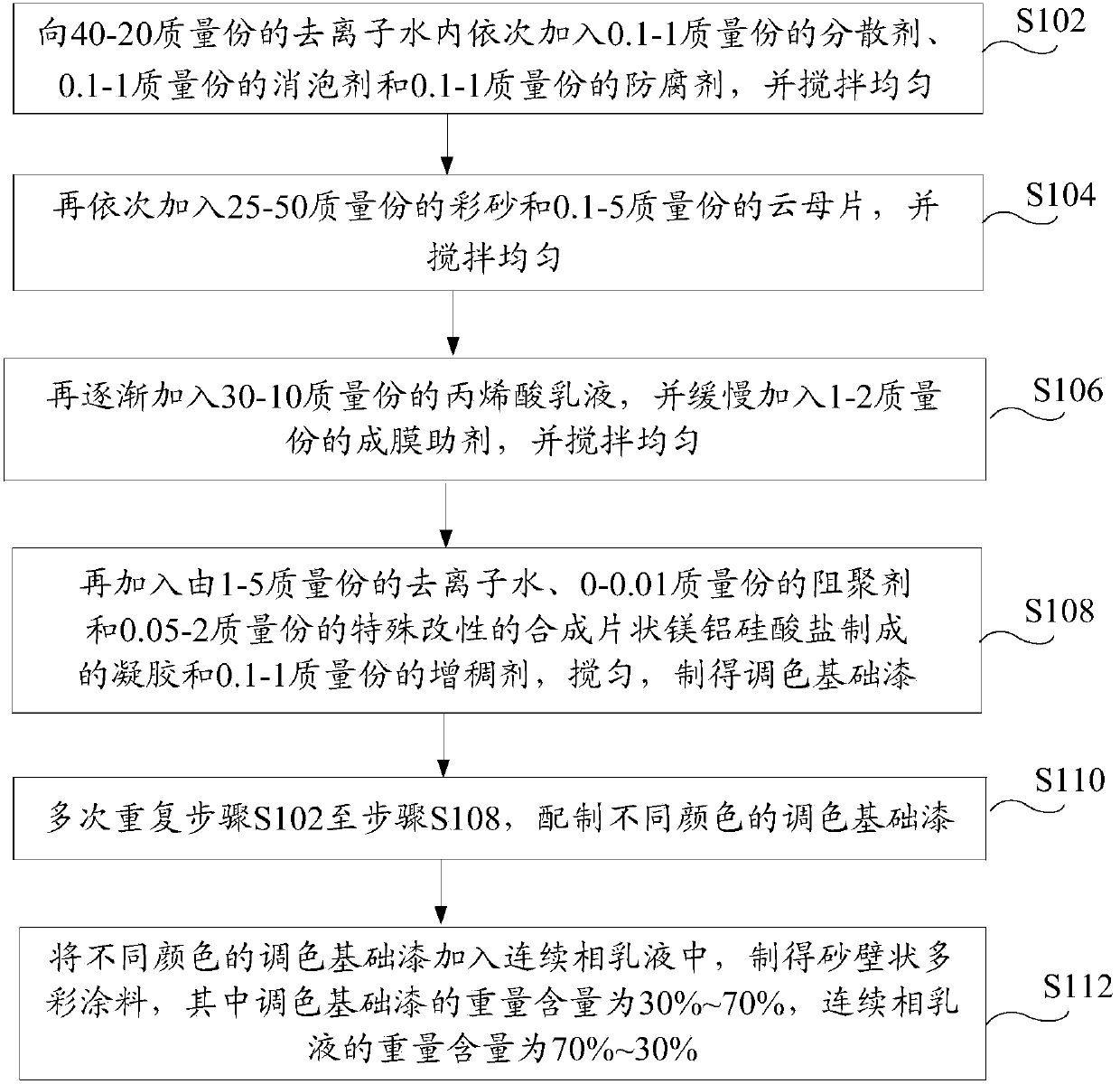

[0058] The embodiment of the third aspect of the present invention provides a kind of preparation method of sand wall shape colorful paint, such as figure 1 shown, including the following steps:

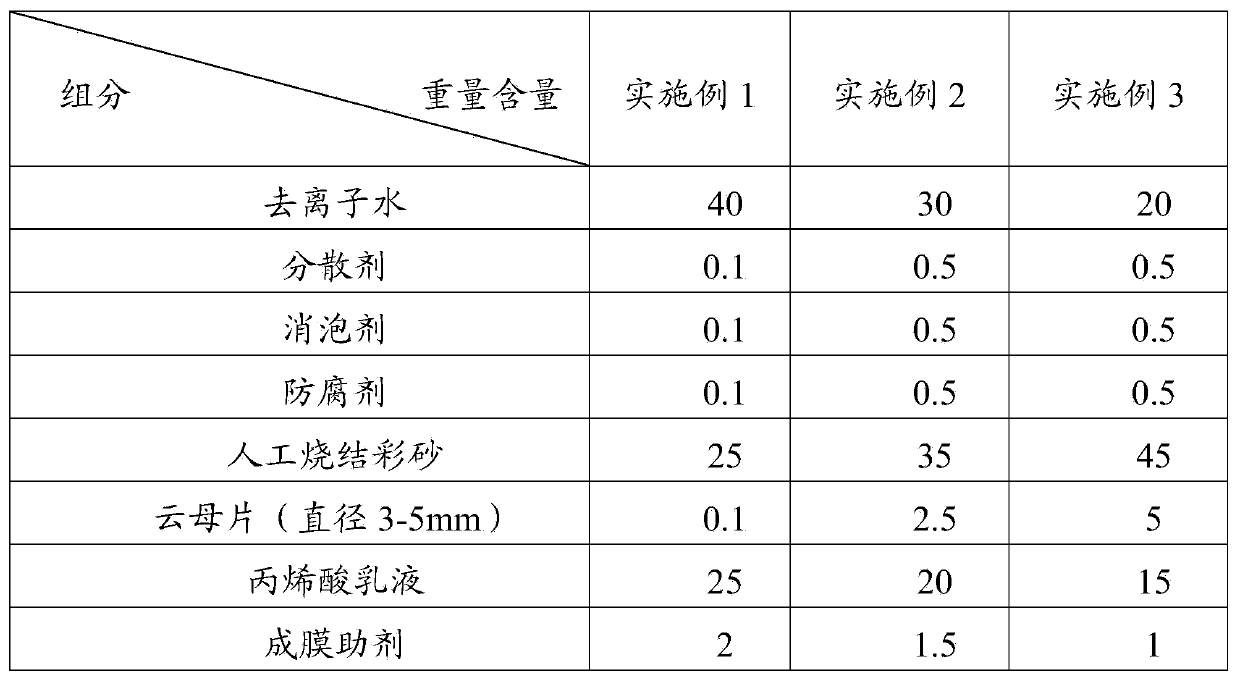

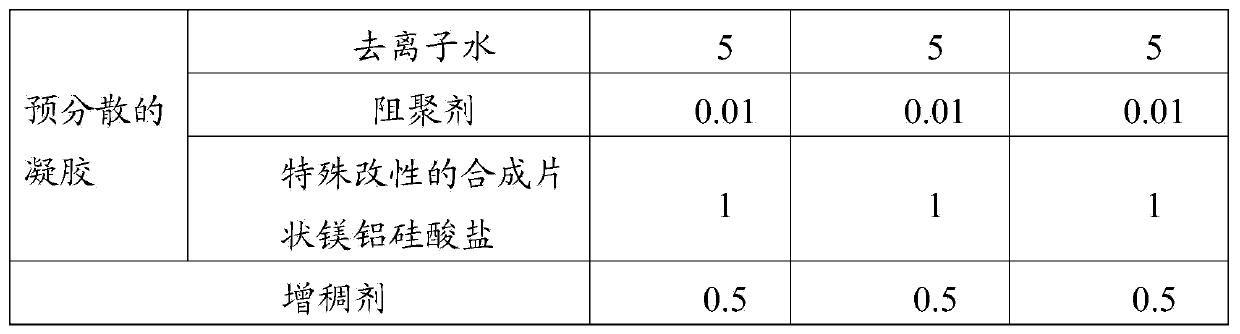

[0059] Step S102, sequentially add 0.1-1 mass part of dispersant, 0.1-1 mass part of defoamer and 0.1-1 mass part of preservative to 40-20 mass parts of deionized water, and stir evenly, the The conductivity of deionized water is ≤6μS / cm;

[0060] Step S104, adding 25-50 parts by mass of colored sand and 0.1-5 parts by mass of mica flakes in sequence, and stirring evenly;

[0061] Step S106, then gradually add 30-10 parts by mass of acrylic acid emulsion, and slowly add 1-2 parts by mass of film-forming aid, and stir evenly;

[0062] Step S108, adding gel made of 1-5 parts by mass of deionized water, 0-0.01 parts by mass of polymerization inhibitor and 0.05-2 parts by mass of specially modified synthetic sheet-shaped magnesium aluminum silicate and The thickener of 0.1-1 mass part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com