Water-dispersible resin varnish and preparation method thereof

A dispersion type, resin paint technology, applied in the direction of coating, etc., to achieve good decorative effect, excellent performance index, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A water-dispersible resin paint, the preparation method is as follows:

[0024] (1) Put 33 grams of R-706 titanium dioxide, 33 grams of deionized water, and 1 gram of BYK-180 in a sand mill, put in glass beads, and grind for 1 hour to obtain a white slurry;

[0025] (2) Put 20 grams of WAC 2501A water-dispersed acrylic resin (solid content: 40%, viscosity (mPa.s): 2000-7000, pH value: 7.0-8.5) in a container, and slowly add 5.8 grams of amino resin ( cymel303, 60%, BCS diluted), after stirring evenly, then add 0.1 gram of benzenesulfonic acid catalyst, after continuing to stir evenly, then add 23 grams of deionized water, 4 grams of talcum powder, and 38.9 grams of white slurry, Stir evenly, then continue to disperse the mixture on the mixer at a speed of 800r / min for 15 minutes, filter with a 200-mesh filter cloth, and the obtained filtrate is to be used on the spray board;

[0026] (3) Put 60 grams of WAC 2503D water-dispersed acrylic resin (solid content: 40%, visco...

Embodiment 2

[0029] A water-dispersible resin paint, the preparation method is as follows:

[0030] (1) Put 38 grams of R-706 titanium dioxide, 28 grams of deionized water, and 1.2 grams of BYK-180 in a sand mill, put in glass beads, and grind for 1 hour to obtain a white slurry;

[0031] (2) Put 25 grams of WAC 2501A water-dispersed acrylic resin (solid content: 40%, viscosity (mPa.s): 2000-7000, pH value: 7.0-8.5) in a container, and slowly add 6.5 grams of amino resin ( cymel303, 60%, BCS diluted), after stirring evenly, then add 0.2 g of benzenesulfonic acid catalyst, continue stirring evenly, then add 23.5 g of deionized water, 5 g of talcum powder, and 41 g of white slurry, Stir evenly, then continue to disperse the mixture on the mixer at a speed of 800r / min for 15 minutes, filter with a 200-mesh filter cloth, and the obtained filtrate is used for the spray plate;

[0032] (3) Put 70 grams of WAC 2503D water-dispersed acrylic resin (solid content: 40%, viscosity (mPa.s, 25°C): 5000...

Embodiment 3

[0035] A water-dispersible resin paint, the preparation method is as follows:

[0036](1) Put 43 grams of R-706 titanium dioxide, 33 grams of deionized water, and 1.5 grams of BYK-180 in a sand mill, put in glass beads, and grind for 1 hour to obtain a white slurry;

[0037] (2) Put 30 grams of WAC 2501A water-dispersed acrylic resin (solid content: 40%, viscosity (mPa.s): 2000-7000, pH value: 7.0-8.5) in a container, and slowly add 7.7 grams of amino resin ( cymel303, 60%, BCS diluted), after stirring evenly, then add 0.5 g of benzenesulfonic acid catalyst, continue stirring evenly, then add 24 g of deionized water, 6 g of talcum powder, and 45 g of white slurry, Stir evenly, then continue to disperse the mixture on the mixer at a speed of 800r / min for 15 minutes, filter with a 200-mesh filter cloth, and the obtained filtrate is to be used on the spray board;

[0038] (3) Put 80 grams of WAC 2503D water-dispersed acrylic resin (solid content: 40%, viscosity (mPa.s, 25°C): 50...

PUM

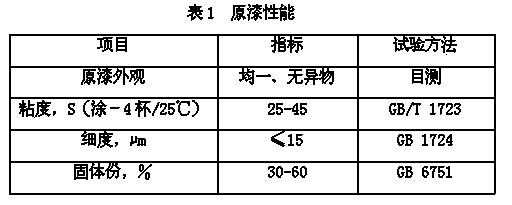

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap