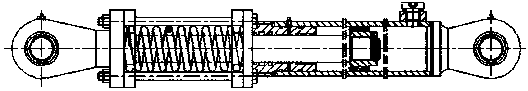

Oil-gas two-medium damping hydraulic cylinder

A hydraulic cylinder and dual-medium technology, applied in the field of hydraulic cylinders, can solve problems such as difficulty in maintaining consistent spring performance, spring fatigue failure, and uneven quality of the entire cylinder, and achieve stable product quality, extended service life, and simple external structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

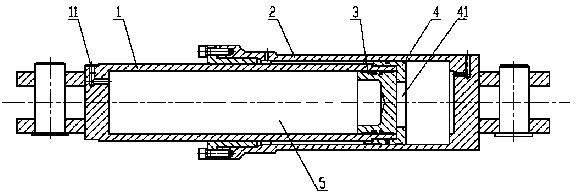

[0019] like figure 2 As shown, an oil-air dual-media damping hydraulic cylinder includes a cylinder barrel 2, a piston rod 1 and a piston 4 installed at the right end of the piston rod 1; A blind hole opened at the right end; the floating piston 3 is fitted in the inner chamber 5, and there are several grooves on the cylindrical surface where the floating piston 3 cooperates with the inner wall of the inner chamber 5, and sealing rings and guide elements are installed in the grooves, and the floating piston 3 can slide left and right in the inner cavity 5, a counterbore is opened in the center of the left end face of the floating piston 3, and the right end face of the floating piston 3 is a plane; There is an oil passage 41 connecting the rodless cavity of the hydraulic cylinder and the inner cavity 5 on the right side of the floating piston 3; The L-shaped channel is connected to the inner cavity 5 . When in use, the inner chamber 5 on the left side of the floating piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com