Aero-engine combustor with variable-cross-section step-shaped multiple-inclined-hole cooling structure used

An aero-engine and combustion chamber technology, applied in the field of aero-engines, can solve problems such as adverse effects of engine weight, increased processing difficulty, decreased cooling capacity, etc., and achieve the effects of increased combustion gas consumption, effective cooling, and increased temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

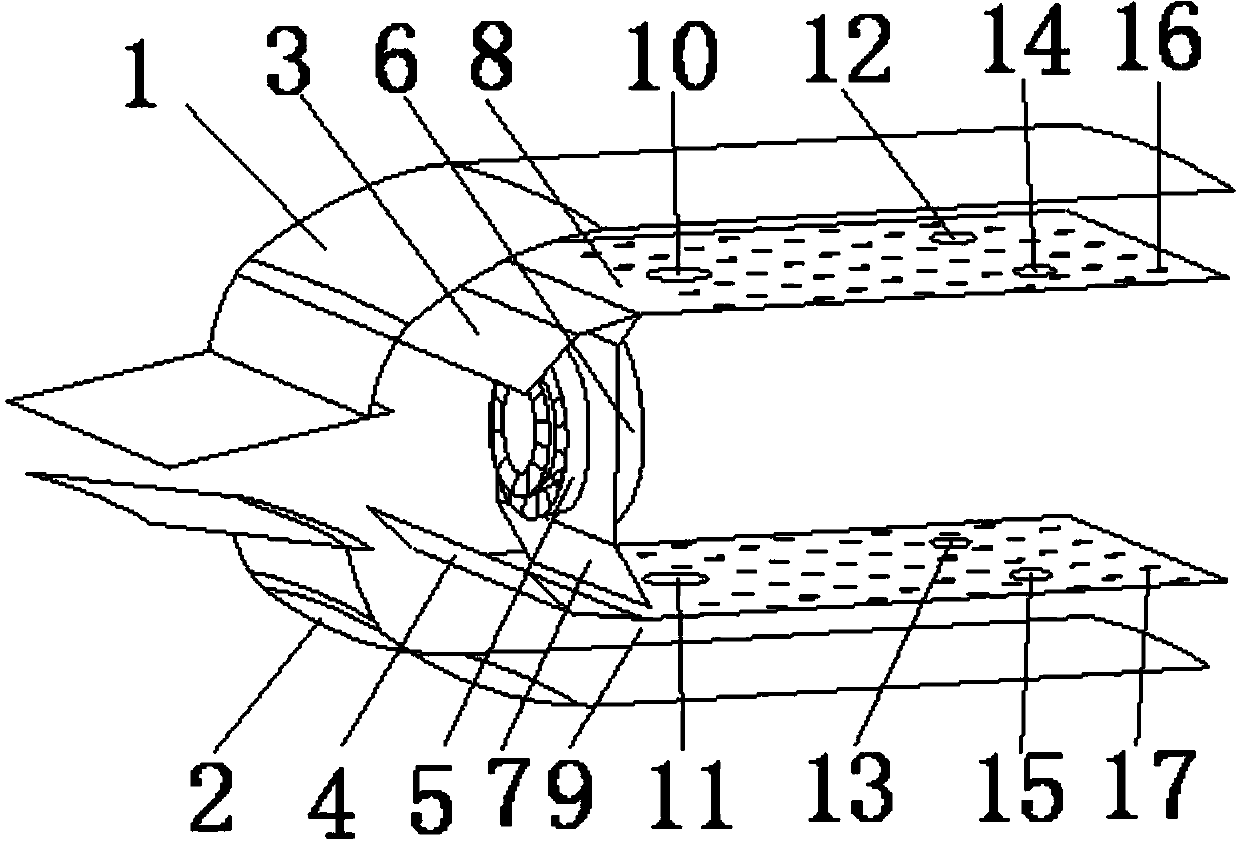

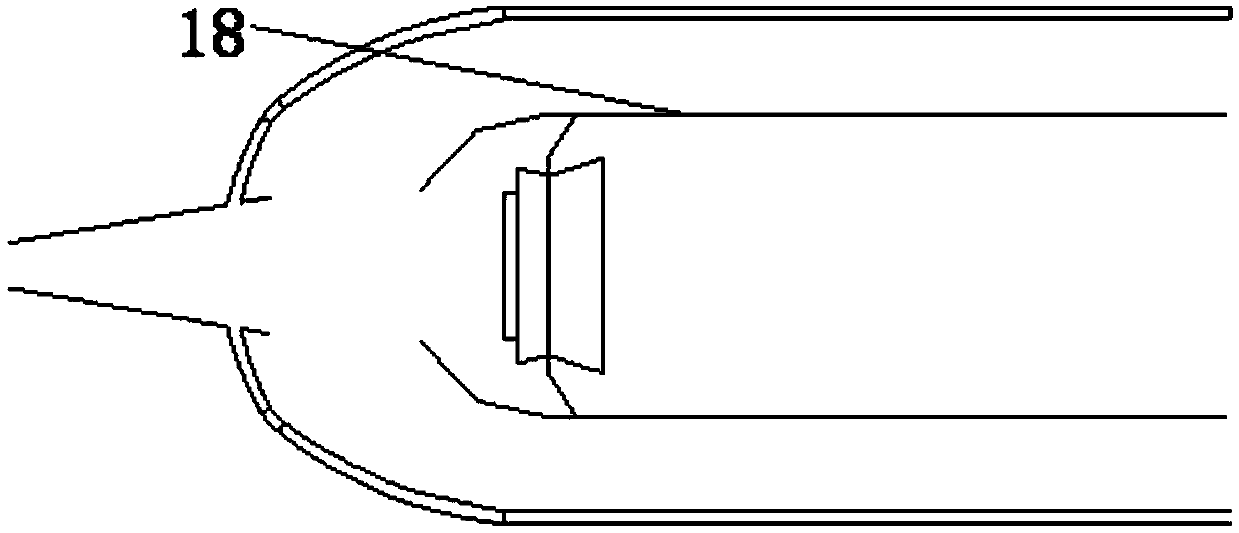

[0036] An aero-engine combustor adopting a stepped multi-slope hole cooling structure with variable cross-section, such as figure 1 , figure 2 As shown, it includes the first combustion chamber casing 1, the second combustion chamber casing 2, the first cap 3, the second cap 4, the outer ring wall of the flame tube 8, the inner ring wall of the flame tube 9, and the flame tube 18, Its technical solution is:

[0037] 1) The front end of the flame tube 18 adopts axial positioning, and the rear end of the flame tube 18 cooperates with the first combustion chamber casing 1 and the second combustion chamber casing 2, adopts radial and circumferential positioning, and allows free thermal expansion in the axial direction;

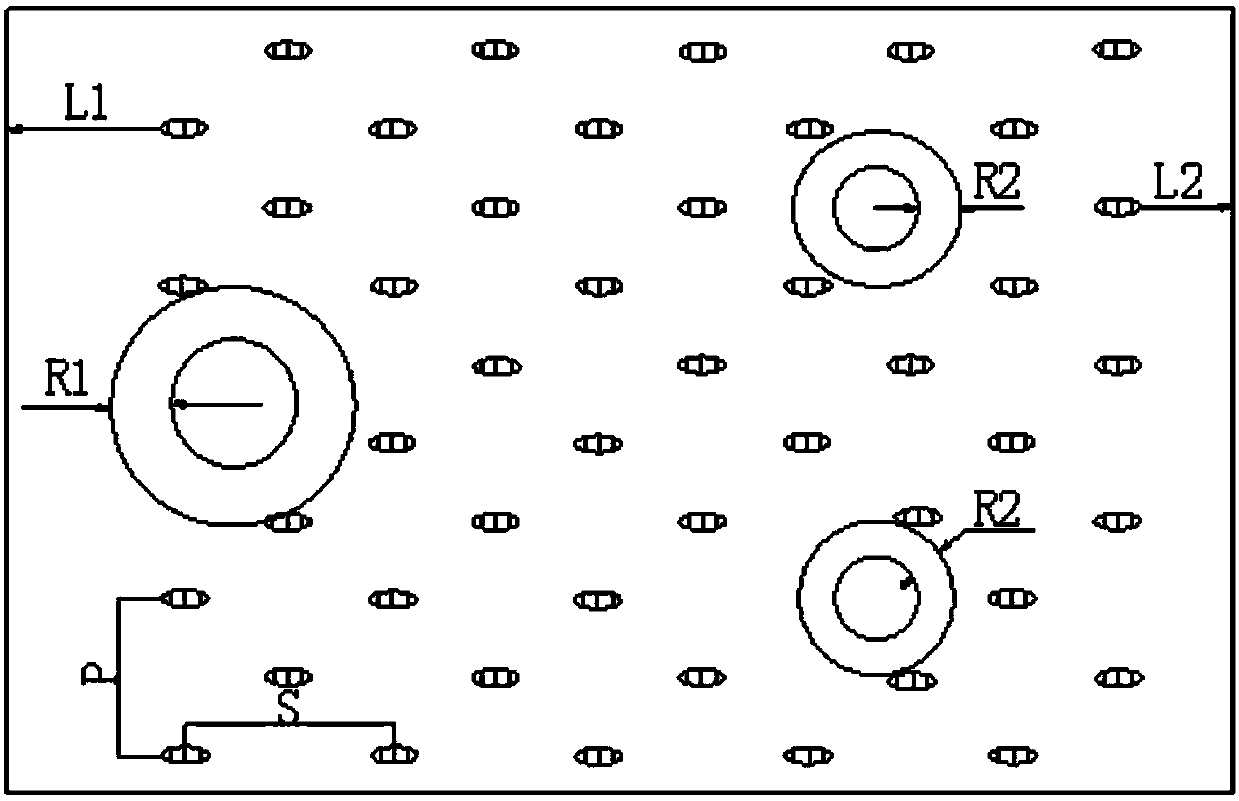

[0038] 2) Flame tube 18 includes flame tube outer ring wall 8 and flame tube inner ring wall 9, connecting section 7 connects flame tube outer ring wall 8 and flame tube inner ring wall 9, and flame tube outer ring wall 8 and flame tube inner ring The wall 9 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com