Flowing wet steam wetness measuring system and method

A technology of flowing wet steam and humidity measurement, applied in the direction of analyzing materials, instruments, etc., it can solve the problems of complex measurement principle and system, inability to realize real-time measurement, and unsatisfactory measurement results, so as to ensure accuracy, accurate and reliable measurement results, The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

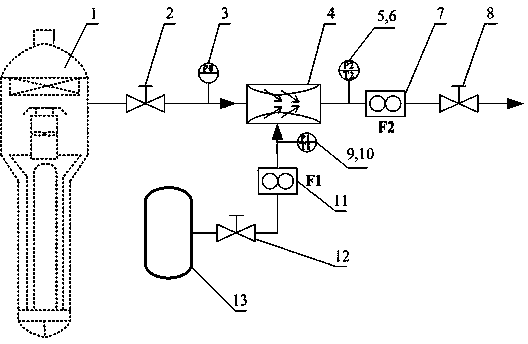

[0044] Such as figure 1 Shown, flow wet steam humidity measurement system, including:

[0045] The superheated steam source 13 is used to provide superheated steam. The superheated steam is mainly used to heat the wet steam sampled from the steam generator 1. In order to ensure the effective heating of the wet steam, the superheated degree of the superheated steam provided should be greater than 20°C. The pressure is higher than the pressure of the steam generator 1 sampling point, which is beneficial to steam mixing, and the superheated steam flow rate should be sufficient to ensure that the mixed steam is in a superheated state. The superheated steam source 13 can adopt a general steam generator that can meet the demand, or A special superheated steam generator can be used;

[0046] The steam mixing device 4 is used to fully mix the sampled wet steam and superheated steam to ensure uniform steam temperature after mixing;

[0047] The sampling inlet section is connected bet...

Embodiment 2

[0059] On the basis of Embodiment 1, a back pressure valve 8 is provided on the mixed steam outlet section of the flowing wet steam humidity measurement system in this embodiment, and the back pressure valve 8 is located near the outlet end of the mixed steam outlet section. The operating pressure of the system and the flow rate of the mixed steam can be adjusted through the steam back pressure valve 8.

Embodiment 3

[0061] On the basis of Embodiment 1 or 2, in order to minimize the heat exchange between the wet steam and superheated steam in the steam mixing device and the outside, resulting in heat loss, the outer surface of the steam mixing device 4 is provided with an insulating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com