Method and device for detecting cloth flaws based on adaptive orthogonal wavelet transform

An orthogonal wavelet and detection method technology, which is applied in the direction of optical detection of defects/defects, can solve the problems of insufficient detection accuracy of cloth defects and the inability to ensure the matching of wavelet bases and fabric textures, etc., achieving good application prospects, high accuracy, overcoming the effect of slowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

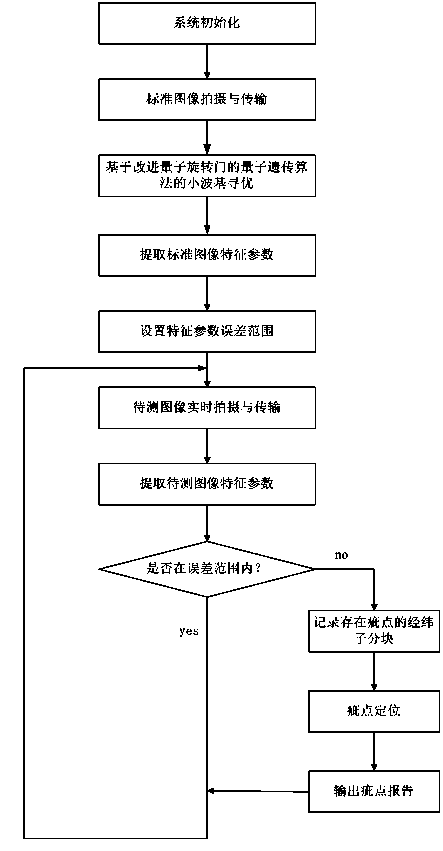

[0027] like figure 1 As shown, the cloth defect detection method based on adaptive orthogonal wavelet transform includes the following steps:

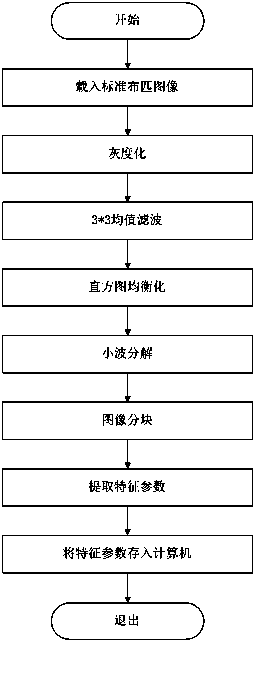

[0028] Step 1: Obtain a non-defective cloth image and input it into the computer as a standard cloth image. For example, an industrial camera can be used to capture a non-defective cloth image, and the acquired cloth image can be sent to the computer as a standard cloth image.

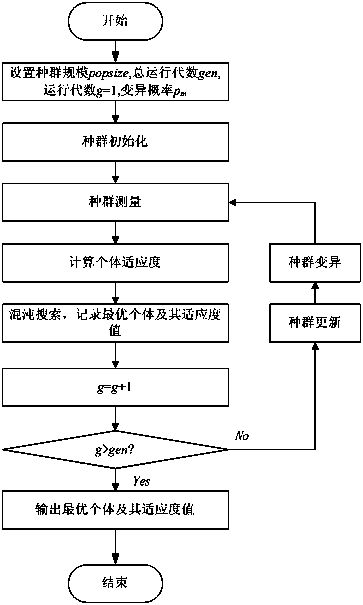

[0029] Step 2: Use the improved quantum revolving door quantum genetic algorithm to obtain the optimal wavelet base that matches the texture of the standard cloth image, and store the optimal wavelet base in the computer.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com