Method for measuring and compensating absolute positioning accuracy of precise positioning platform

An absolute positioning accuracy and precise positioning technology, which is applied in the photoplate making process, optics, and instruments of the patterned surface, can solve the problems of high cost, high price, and high environmental requirements, and achieve low cost, easy operation, and measurement accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

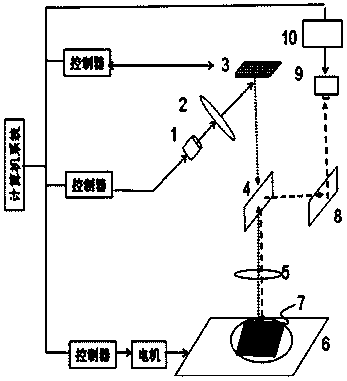

[0028] like figure 1 As shown, the hardware system of the direct writing lithography equipment includes an exposure light source 1, a spatial light modulator 3, a substrate 7 installed on a mobile platform 6, the mobile platform 6 is connected to a motor, the motor is connected to a platform controller, the exposure light source 1, the spatial light modulator An optical integration system 2 is installed between the modulators 3, an inclined beam splitter 4 and a lens or lens group 5 are arranged between the spatial light modulator 3 and the substrate 6, and the reflected light of the beam splitter 4 enters the CCD in the imaging module Camera 9, CCD camera 9 is connected with image processing module 10.

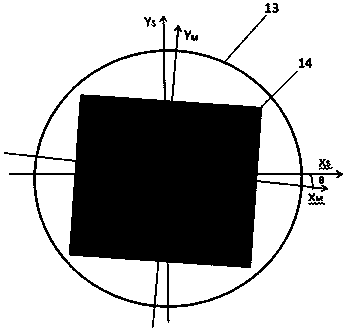

[0029] like Figure 2-6 As shown, a method for measuring and compensating the absolute positioning accuracy of a precision positioning platform includes the following steps:

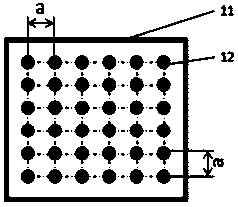

[0030] 1. If figure 2 As shown, the mask plate 11 is fixed on the sucker of a lithography equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com