A feal soft magnetic alloy with high magnetostriction coefficient

A technology of magnetostriction coefficient and soft magnetic alloy, which is applied in the field of oscillator components and FeAl soft magnetic alloy, can solve the problems that hinder the miniaturization and light weight of modern devices, cannot meet application requirements, and difficult machining, and achieve good machining. Good performance, good plasticity, comprehensive performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

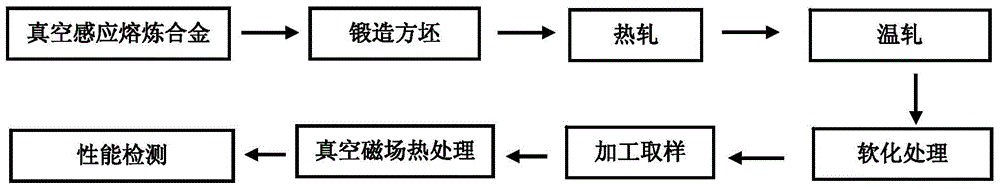

[0043] The concrete preparation method of the FeAl soft magnetic alloy of high magnetostriction coefficient of the present invention comprises the following steps:

[0044] a) Proportioning the raw materials and melting the alloy in a vacuum induction furnace;

[0045] b) High temperature forging, the forging temperature is 1150±20℃;

[0046] c) Continuously hot rolling the forged block to 2.5-3.5mm;

[0047] d) Warm rolling processing of plates to 0.2-0.4mm;

[0048] e) Use a muffle furnace to soften the alloy, and then oil quench, that is, heat the alloy to 650±20°C in the air with the furnace, and keep it warm for 120±10min;

[0049] f) Processing and sampling;

[0050] g) Vacuum heat-treat the alloy at 950±20°C, keep it warm for 120±10min, and at the same time, apply a DC magnetic field with a magnetic field strength of 40±5Oe;

[0051] h) Perform corresponding performance tests on the alloy samples treated according to steps a-g.

Embodiment

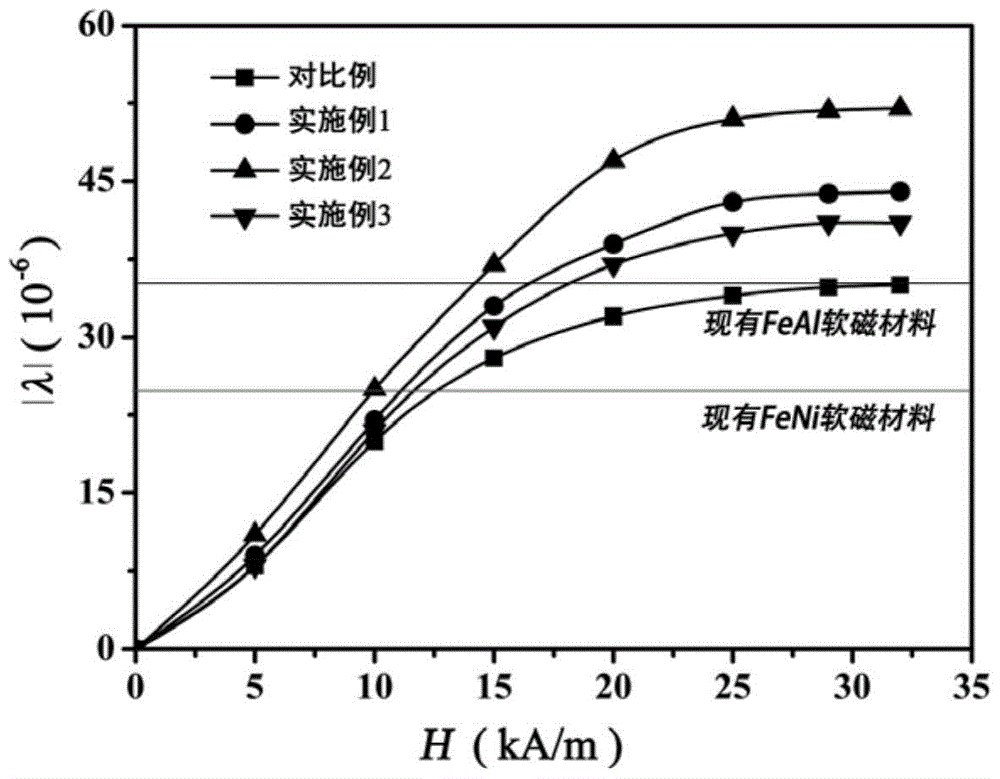

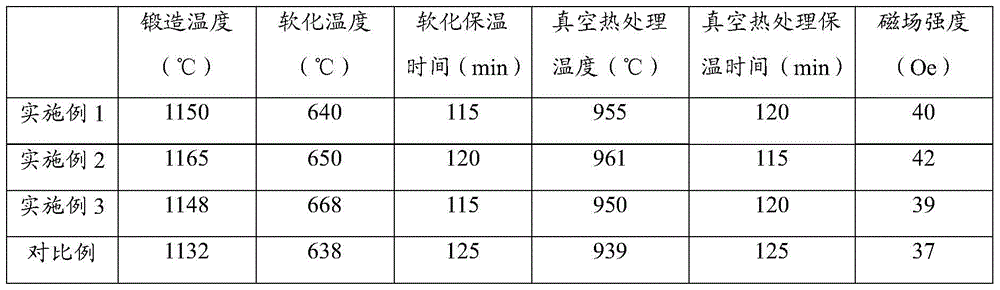

[0053] The chemical composition of the present invention is used to prepare FeAl soft magnetic alloy with high magnetostriction coefficient taking into account both magnetic properties and processability, and its chemical composition is shown in Table 1 (Example 1, Example 2 and Example 3). For the convenience of comparison, the FeAl alloy (comparative example) prepared by the prior art is also listed in Table 1 at the same time.

[0054] Table 1 Chemical Composition of Smelted Alloy (wt.%)

[0055] Al Mg Tb Mn Si C P S Fe Example 1 11.6 0.010 5.0 0.10 0.11 0.03 0.010 0.010 margin Example 2 14.0 0.005 5.9 0.05 0.12 0.02 0.010 0.008 margin Example 3 16.3 0.002 6.8 0.08 0.10 0.03 0.005 0.009 margin comparative example 13.6 — — 0.10 0.15 0.03 0.009 0.010 margin

[0056] The preparation process adopted for the alloy of the above composition: vacuum induction melting alloy→forging billet→hot rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com