Insulating mineral foam

A foam and mineral technology, applied in solid waste management, sustainable waste treatment, building components, etc., can solve the problem of not providing enough stable mineral foam, achieve low density, good stability, and reduce thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

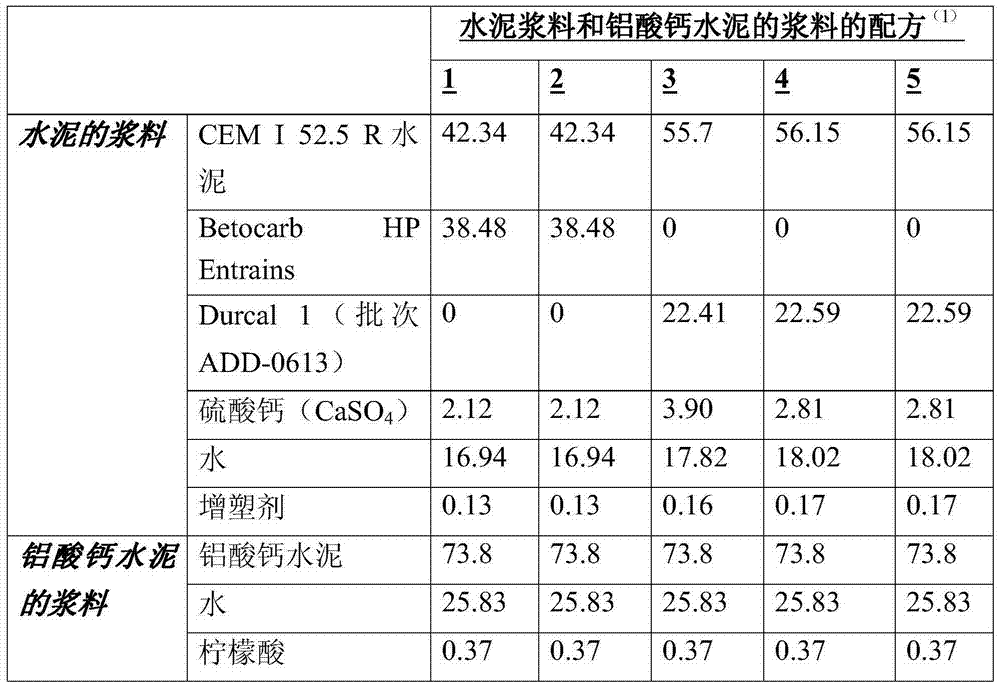

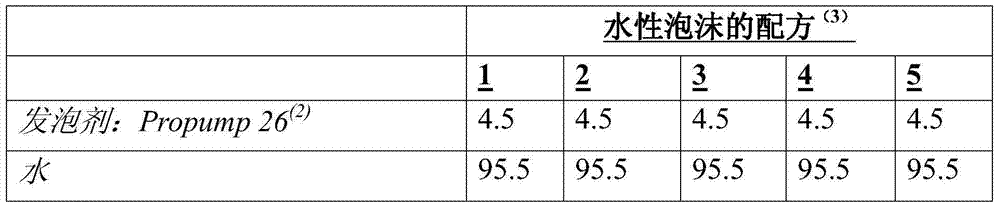

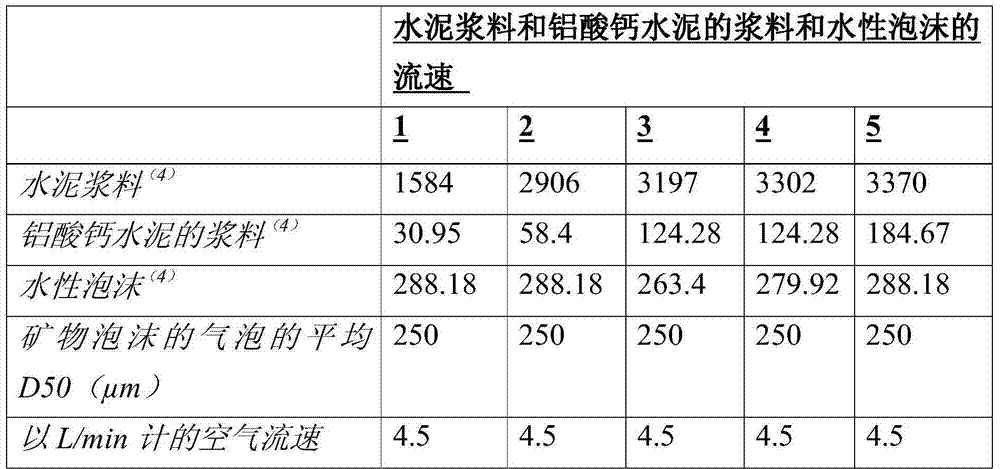

Method used

Image

Examples

Embodiment

[0199] laser particle size method

[0200] In this specification including the appended claims, particle size distribution and particle size are measured using a Malvern MS2000 laser particle sizer. Measurements are carried out in ethanol. The light source consists of a red He-Ne laser (632nm) and a blue diode (466nm). The optical model is Mie optical model, and the calculation matrix is polydisperse.

[0201] The device was checked against a standard of known particle size distribution (Sibelco C10 silica) prior to each work session.

[0202] The measurements were carried out with the following parameters: pump speed 2300 rpm, stirrer speed 800 rpm. Samples were introduced to produce a darkness between 10 and 20%. Measurements are taken after the darkness has stabilized. First apply ultrasound at 80% for 1 min to ensure deagglomeration of the sample. After about 30s (for cleaning up possible air bubbles), the test is performed for 15s (15000 analysis images). Withou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com