Food additive for lupine milk as well as preparation method and application of food additive for lupine milk

A technology for food additives and lupins, which is applied in the field of food additives to achieve the effects of mellow flavor, excellent emulsifying effect, and enhancing system suspending ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of food additives for lupine soymilk and preparation of lupine soymilk thereof

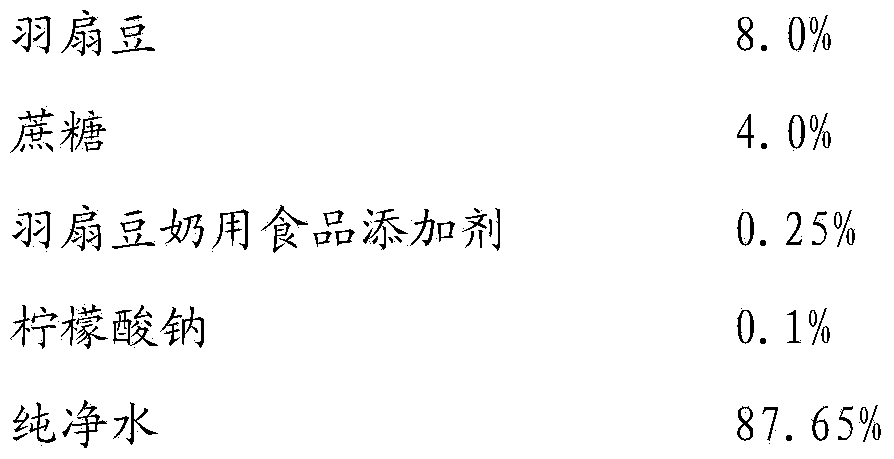

[0030] Each embodiment of table 1 lupine soybean milk food additive formula table (w / w%)

[0031]

Example 1

Example 2

Example 3

Example 4

Example 5

[0032]

40

20

25

20

30

Sucrose Fatty Acid Ester

20

30

25

20

22

Sodium Carboxymethyl Cellulose (FH9)

20

30

22

40

25

7

10

8

5

6

13

10

20

15

17

[0033] 1. Preparation of food additives for lupine soybean milk

[0034] The formula is shown in Table 1. The preparation method is as follows:

[0035] (1) Weighing: take by weighing above-mentioned each monomer component according to proportioning weight requirement;

[0036] (2) Mixing: Add the weighed compone...

Embodiment 2

[0051] Embodiment 2: Preparation of food additives for lupine soymilk and preparation of lupine soymilk thereof

[0052]1. Preparation of food additives for lupine soybean milk

[0053] The formula is shown in Table 1. See Example 1 for the preparation method.

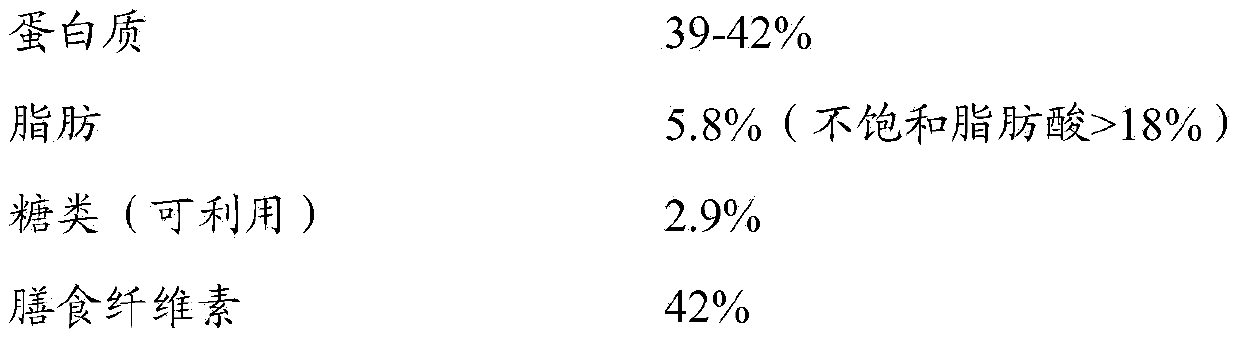

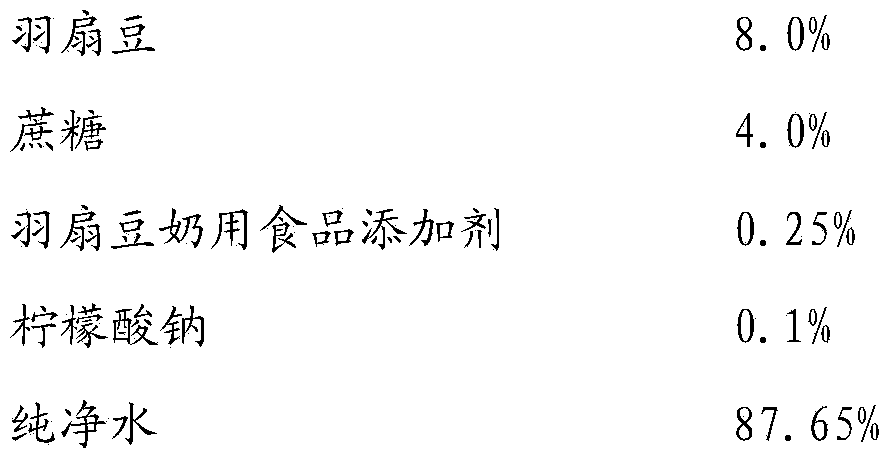

[0054] 2. Preparation of Lupine Soymilk

[0055] The formula is the same as in Example 1 (the food additive for lupine milk used is obtained in Step 1 of Example 2), and the preparation method is the same as in Example 1.

[0056] The finished product is in a stable state during the shelf life of 6-8 months, no obvious precipitation, no flocculation, the height of the floating fat circle is less than 1mm, the viscosity is 29.8mPa·s, the taste is thick, mellow and smooth.

Embodiment 3

[0057] Embodiment 3: Preparation of food additives for lupine soymilk and preparation of lupine soymilk thereof

[0058] 1. Preparation of food additives for lupine soybean milk

[0059] The formula is shown in Table 1. See Example 1 for the preparation method.

[0060] 2. Preparation of Lupine Soymilk

[0061] The formula is the same as in Example 1 (the food additive for lupine milk used is obtained in Step 1 of Example 3), and the preparation method is the same as in Example 1.

[0062] The finished product is in a stable state during the shelf life of 6-8 months, no obvious precipitation, no flocculation, the height of the floating fat circle is less than 1mm, the viscosity is 26.3mPa·s, the taste is thick, mellow and smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com