Pollen pini water washing impurity removing equipment and production process method of high-purity pollen pini

A technology of pine pollen and equipment, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as inability to effectively separate impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

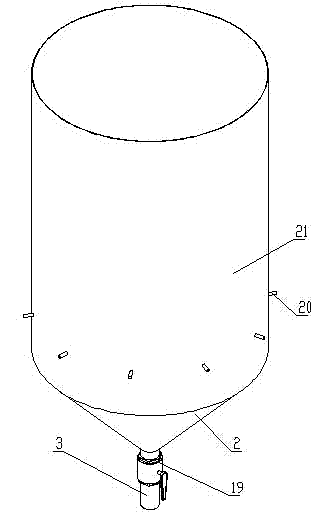

[0040] Embodiment 1: One of the equipment for washing and removing impurities of pine pollen

[0041] see figure 1 , one of the pine pollen water washing and impurity removal equipment, consists of a material tank containing pine pollen slurry and a bubbling device that introduces air inside the slurry; the material tank is composed of an open cylindrical container A21 and a cone-shaped container 2, and the cylindrical The lower part of the conical container A21 is connected and communicated with the large end of the conical container 2, and the small end of the conical container 2 is equipped with a sand discharge pipe 3 with a valve 19; the bubbling device is inserted into the air pipe C20 inside the material tank, and the air pipe C20 is imported Linked to each other with high-pressure gas source, trachea C20 diameter is 15 millimeters, has 12 pieces.

Embodiment 2

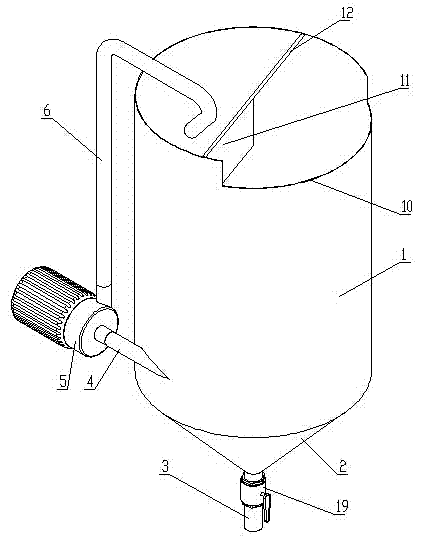

[0042] Embodiment 2: Pine pollen water washing impurity removal equipment two

[0043] see figure 2 , the second of pine pollen washing and impurity removal equipment is composed of a material tank and a bubbling device; the material tank is composed of an open cylindrical container 1 and a cone-shaped container 2, and the lower part of the cylindrical container 1 is connected with the bulk of the cone-shaped container 2 And connected, the small end face of the cone-shaped container 2 is equipped with a sand discharge pipe 3 with a valve 19; the upper part of the cylindrical container 1 is provided with a foam overflow port 10, and the foam overflow port 10 is a section of the upper part of the cylindrical container 1. Foam overflows; the cylindrical container 1 is also provided with a foam baffle, and the foam baffle is made up of a baffle 11 and a fixture 12, and one end of the baffle 11 is fixed on one side of the foam overflow port 10 on the cylindrical container 1, and t...

Embodiment 3

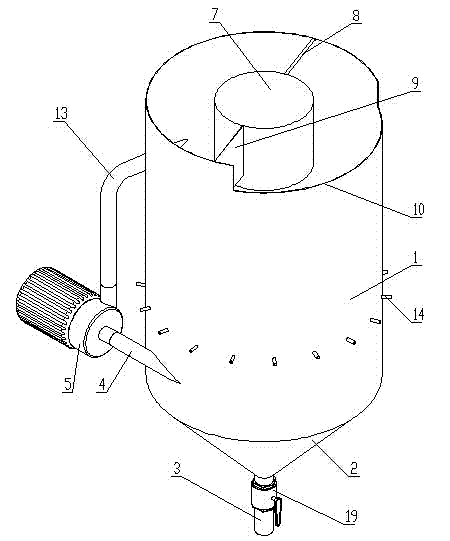

[0044] Embodiment 3: Pine Pollen Water Washing and Impurity Removal Equipment No. 3

[0045] see image 3 , the third of the pine pollen washing and impurity removal equipment is composed of a material tank and a bubbling device; the material tank is composed of an open cylindrical container 1 and a cone-shaped container 2, and the lower part of the cylindrical container 1 is connected with the big end of the cone-shaped container 2 And connected, the small end face of the cone-shaped container 2 is equipped with a sand discharge pipe 3 with a valve 19; the upper part of the cylindrical container 1 is provided with a foam overflow port 10, and the foam overflow port 10 is a section of the upper part of the cylindrical container 1. Foam overflow; the foam baffle is composed of a cylindrical isolator 7, a baffle 9 and a fixing member 8, the cylindrical isolator 7 is arranged in the middle of the upper end of the tank, and one end of the baffle 9 is fixed on the foam overflow por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com