Low-frequency bending vibration type secondary ultrasonic atomizer

A technology of ultrasonic atomizer and bending vibration, applied in the direction of injection device, liquid injection device, etc., can solve the problems of high driving voltage, limited application prospect, heating of circuit and sprayer, etc., and achieve low production cost, light and simple overall structure, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

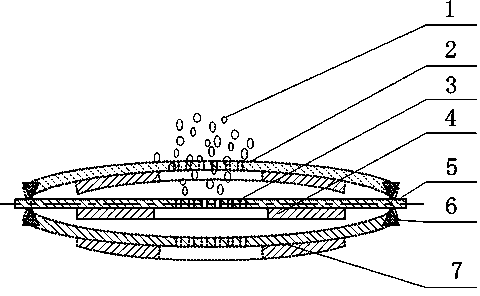

[0024] figure 1 It is a schematic diagram of the working principle of the low-frequency bending vibration ultrasonic nebulizer. Among them, the piezoelectric ceramic 4 is a new type of functional material. The piezoelectric ceramic 4 generates hundreds of thousands of first-order bending vibrations per second through the driving power supply, thereby driving the metal disc 5 to vibrate continuously. The central area of the wafer 5 has extremely small pores 3 . Thereby, the liquid is constantly beaten, so that water is sprayed out from the micropore 3, which ensures the size of the droplet 1 and the sprayed atomization amount per hour.

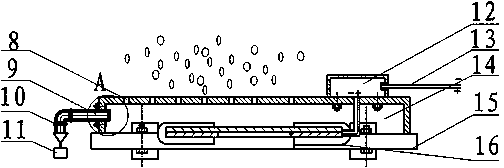

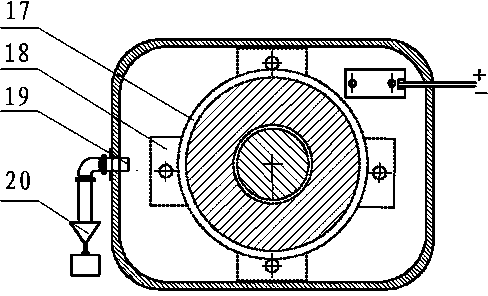

[0025] figure 2 , image 3 It is a cross-sectional view of an embodiment of the low-frequency bending-vibration ultrasonic nebuliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outside diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com