A Melting and Electromagnetically Constrained Forming System with High Efficiency Electrothermal Conversion

An electrothermal conversion and high-efficiency technology, applied in the field of melting and electromagnetic restraint forming systems, can solve the problems of low superheat of high-niobium-titanium aluminum alloy liquid, difficult melting of high-niobium-titanium aluminum alloy, poor structure control effect, etc. Low-cost melting and solidification, high-purity prevention, and improved power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

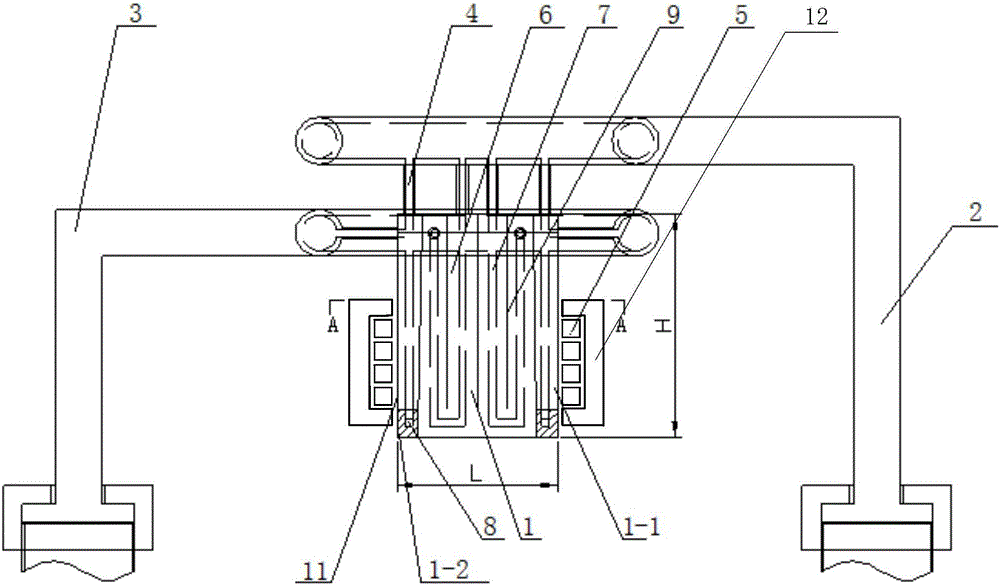

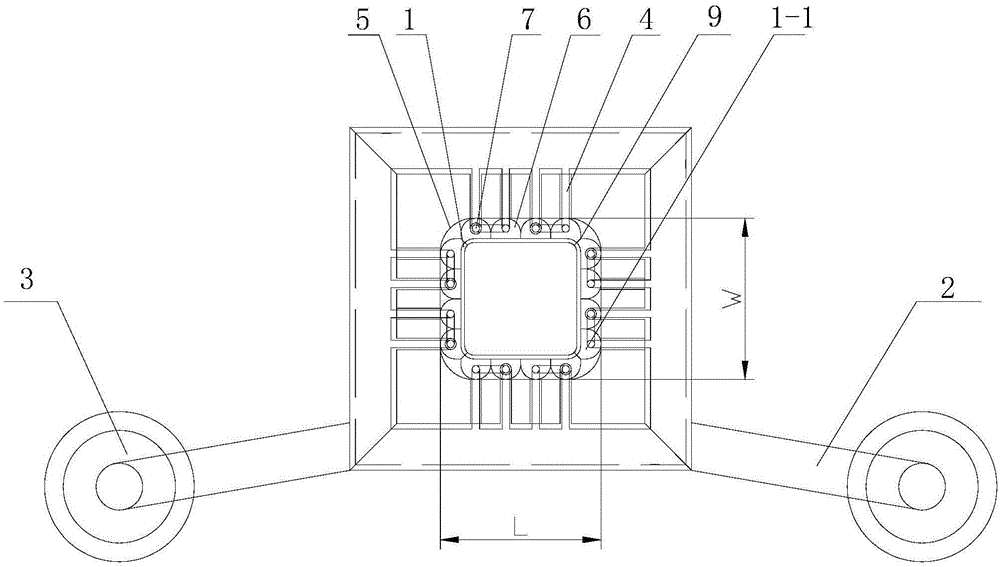

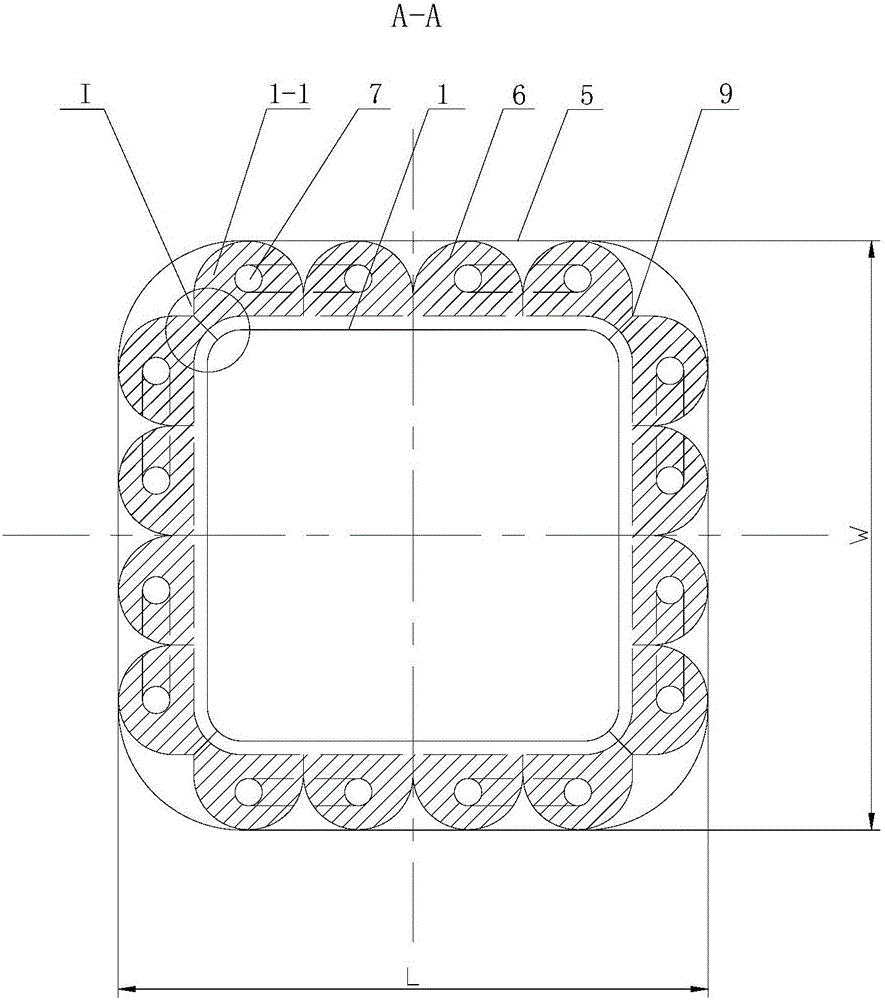

[0033]Specific Embodiment 1: A high-efficiency electrothermal conversion melting and electromagnetic constraining forming system of this embodiment includes: a crucible main body 1, a water inlet pipe 2, a water outlet pipe 3, several thin water pipes 4 and an induction coil 5. The crucible main body 1 is composed of an upper half body 1-1 and a lower half body 1-2, and the upper half body 1-1 and the lower half body 1-2 are processed by wire cutting and drilling from an integral copper block , the water inlet pipe 2 communicates with the lower half body 1-2 through the fine water pipe 4, the outlet pipe 3 communicates with the lower half body 1-2 through the thin water pipe 4, and the induction coil 5 is set on the upper half body 1-1 Above, the cross section of the crucible main body 1 is a square ring hollow body, the upper half body 1-1 is divided into sixteen petal-shaped cylinders 6, and the cylinders 6 are along the cross section of the crucible main body 1. The horizon...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment is different from Embodiment 1 in that: the insulating sealing material layer 10 is an insulating sealing material layer 10 made of natural mica sheet and epoxy resin.

[0045] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Specific embodiment three: This embodiment differs from specific embodiment one or two in that: the thin water pipe 4 and the water inlet pipe 2, the thin water pipe 4 and the water outlet pipe 3, the thin water pipe 4 and the lower half of the crucible main body 1- 2 are connected by welding.

[0047] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com