A device for realizing mobile micro-die-casting of metal components

A metal component and micro-die-casting technology, which is applied in the field of devices for metal component movement and micro-die-casting, can solve the problems of low processing efficiency, no metal component, high manufacturing cost, etc., and achieve the effect of compact structure and effective control of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

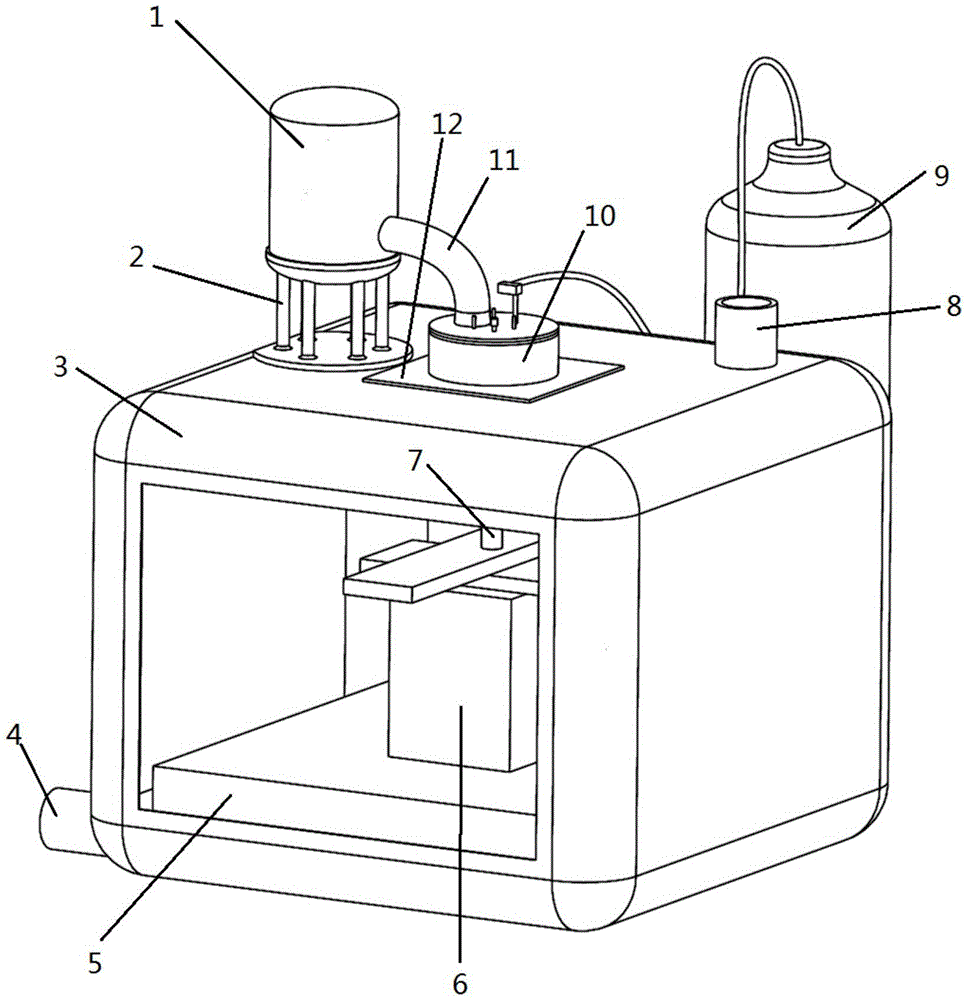

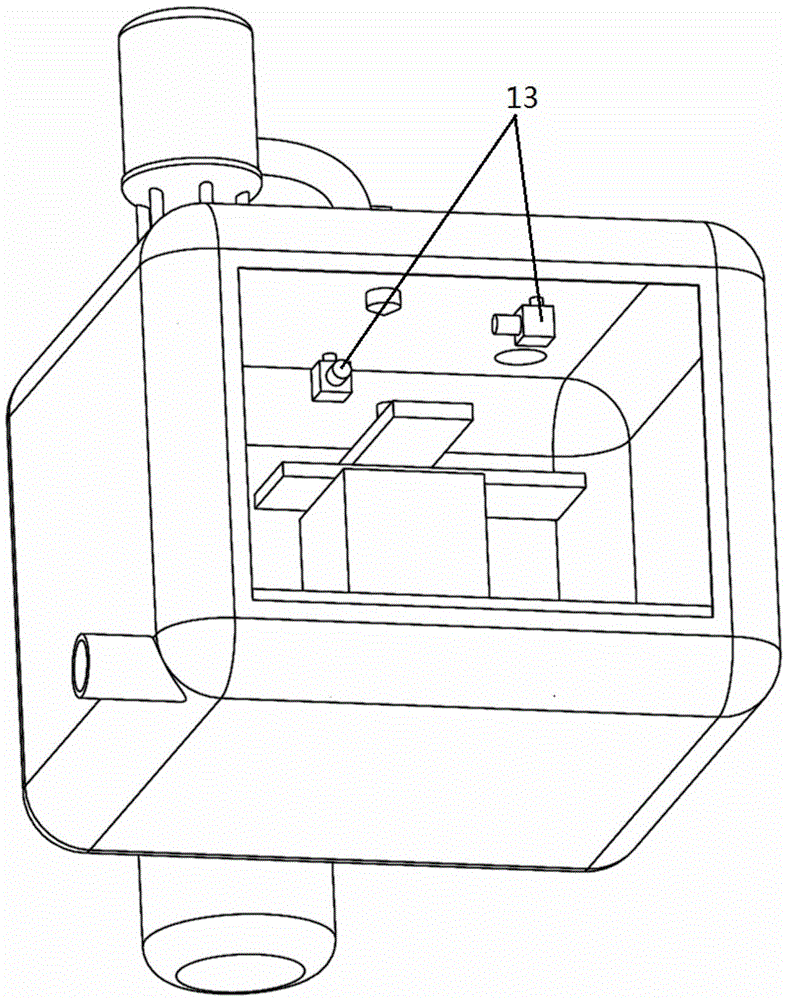

[0029] The basic parts and specific structure of the concrete device of the present invention are shown in figure 1 Shown:

[0030] The smelting furnace 1 is placed on the smelting furnace bracket 2 . During processing, materials required for smelting are added to the smelting furnace 1, and the raw materials are melted by induction or resistance heating.

[0031] One end of the conveying pipeline 11 is arranged at the outlet of the molten metal of the smelting furnace 1, and the other end is arranged at the entrance of the investment casting furnace 10, and is used for transporting the molten metal melted in the smelting furnace 1 to the investment casting furnace 10 by gravity, and the investment casting furnace 10 Insulation and stirring, stirring can be mechanical stirring or electromagnetic stirring.

[0032] 3 is an environmental box, and the environmental protection gas enters through the air inlet 4 and is discharged from the exhaust port 8. Before processing, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com