A kind of LED molding sealing device and sealing method thereof

A sealing device and molding technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of packaging glue sticking to the mold, reducing the yield of molded products, and residual air bubbles in sealing glue products, so as to ensure the integrity of the glue, Increased yield and reduced thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

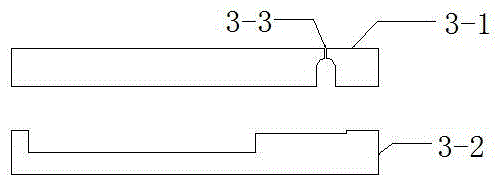

[0040] A LED molding and sealing device, the schematic diagram, cross-sectional view and perspective view of its components are as follows Image 6 , Figure 7 with Figure 8 As shown, it includes an upper mold 3-1, a lower mold 3-2 and a rubber channel partition structure. The upper part of the upper mold 3-1 is provided with a glue injection port 3-3, and the upper part of the lower mold 3-2 is provided with a cavity 3-6. The injection port 3-3 is connected to the cavity 3-6 through the rubber channel 3-5 arranged at the lower part of the upper mold 3-1 and the upper part of the lower mold 3-2, and the upper mold 3-1 and the lower mold 3-2 are locked After the parts are locked, it also includes the glue channel partition structure set in the glue channel 3-5. When injecting glue, the glue thrust will make the glue channel partition structure shift and connect the glue channel 3-5. When the glue injection is completed, the glue thrust will disappear. Reset the rubber channe...

Embodiment 2

[0043] In this embodiment, on the basis of embodiment 1, the rubber channel partition structure is specifically designed, and the schematic diagrams, cross-sectional views and perspective views of each component are as follows Image 6 , Figure 7 with Figure 8 As shown, the rubber channel partition structure includes an inner rubber pool 3-4, a steel ball 3-8 and an elastic member 3-9, one side of the inner rubber pool 3-4 communicates with the rubber channel 3-5, and the upper half of the inner rubber pool 3 -10 and the lower half of the inner glue pool 3-11 are correspondingly arranged on the lower part of the upper mold 3-1 and the upper part of the lower mold 3-2, and the top of the inner glue pool 3-4 is provided with an opening communicating with the injection port 3-3, and The opening is a spherical fitting surface 3-12, the elastic member 3-9 is arranged at the bottom of the inner rubber pool 3-4, the steel ball 3-8 is placed in the inner rubber pool 3-4 and is loca...

Embodiment 3

[0049] In this embodiment, on the basis of embodiment 2, the shape of the inner rubber pool 3-4 is improved, and replaced with a spherical cavity that is more convenient for cleaning and demoulding. Schematic diagrams and cross-sectional views of its components are shown in Figure 9 , Figure 10 As shown, the upper half 3-10 of the inner glue pool and the lower half 3-11 of the inner glue pool are hemispherical.

[0050] The working principle of this embodiment is the same as that of embodiment 2, but, compared with embodiment 2, the inner glue pool 3-4 of this embodiment is spherical, and its capacity is smaller than that of a cuboid, thereby reducing the amount of glue injected and removing It is easier to mold and clear the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com