Conveyor system, textile plant with same and method for starting textile plant

A technology of transmission system, textile equipment, applied in the field of transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

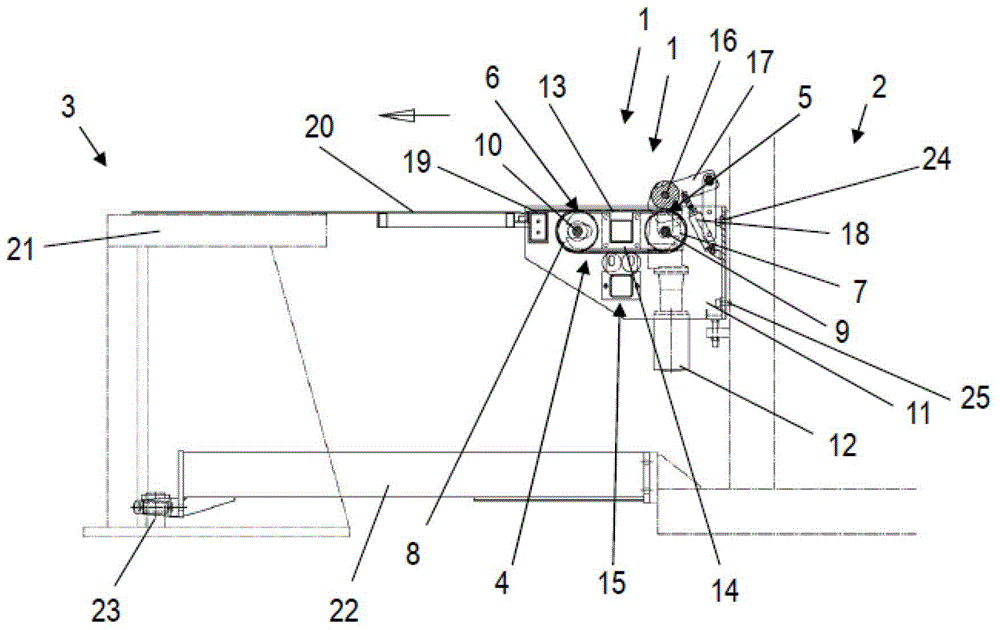

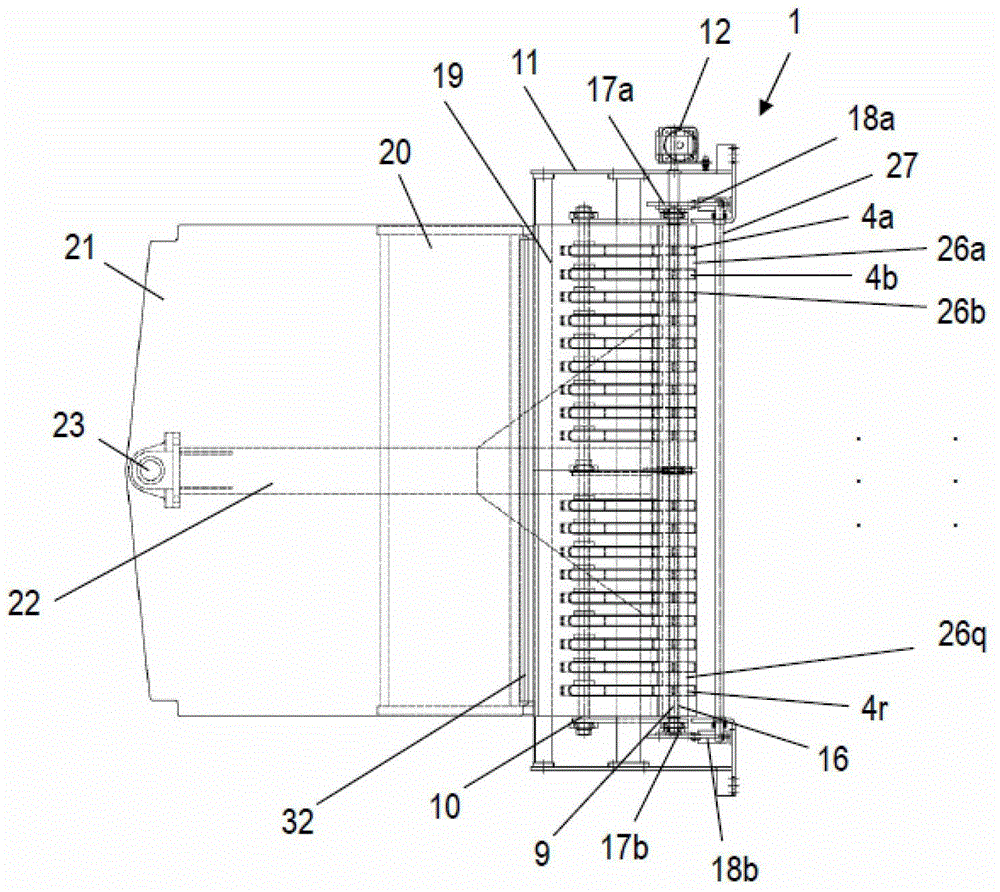

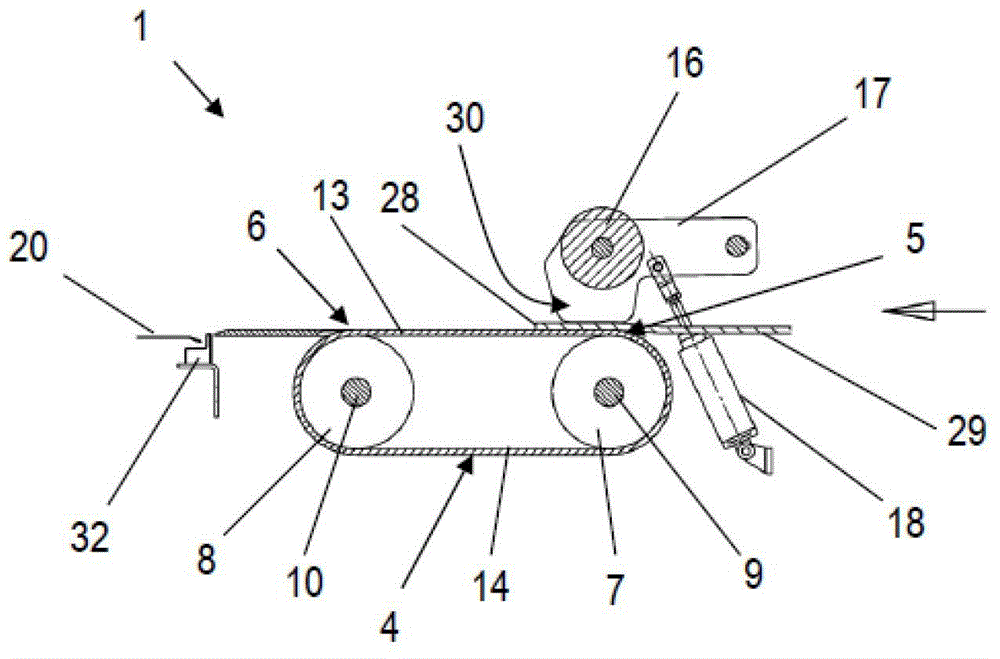

[0045] exist figure 1 A side view of the conveyor system 1 is shown in . The conveyor system 1 is located between two adjacent plant parts: the uncoiling station 2 and the cutting device 3 . In this case, the conveyor system 1, the uncoiling station 2 and the cutting device 3 are part of a textile Figure 6 and 7 is schematically shown in and is used for processing thin and sticky ply strips.

[0046] The conveyor system 1 has a plurality of conveyor belts 4 arranged parallel to one another, which are guided in a loop at a conveyor start 5 and a conveyor end 6 via deflection wheels 7 , 8 . In this case, the deflecting wheels 7 , 8 are mounted rotatably via shafts 9 , 10 in the frame 11 of the conveyor system 1 , respectively. In this case, the shaft 9 arranged at the delivery start 5 can be driven via a drive 12 . The movement of the shaft 9 is transmitted via the deflection pulley 7 to the conveyor belt 4 and to the deflection pulley 8 with its shaft 10 . The strip of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com