Method for extracting araboxylan from astragalus medicine residues by using ionic liquid

A technology of arabinoxylan and ionic liquid, which is applied in the field of traditional Chinese medicine extraction, can solve problems such as the difficulty of separating and purifying arabinoxylan, achieve good social and economic benefits, avoid low yields of enzymatic methods, and avoid environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

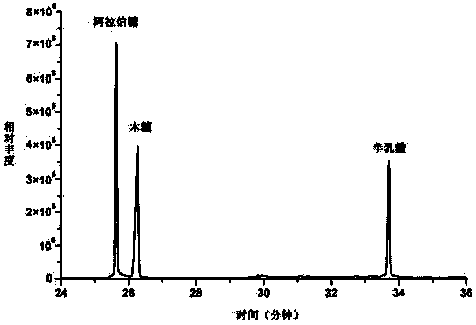

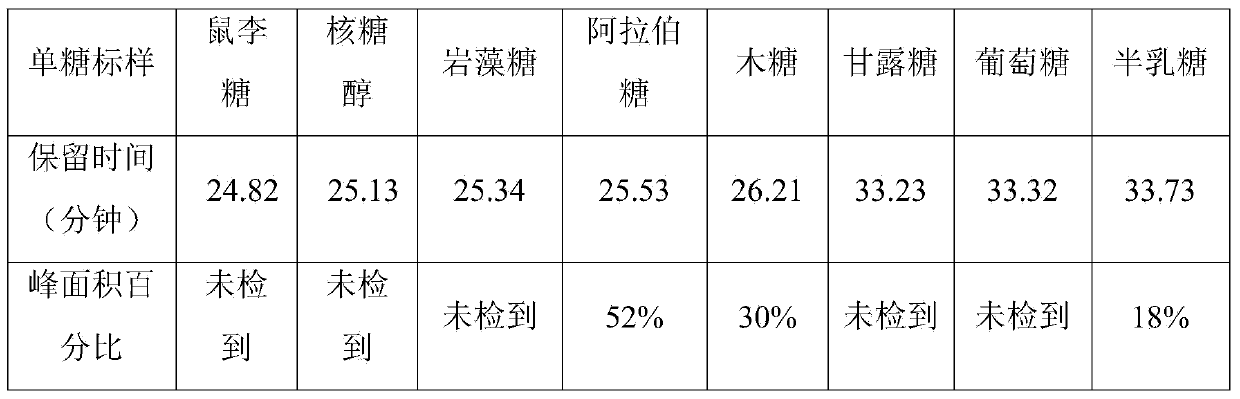

[0019] 1) Extraction of arabinoxylan: the dried astragalus medicinal residues are crushed, passed through a 100-mesh sieve, and set aside; the above powder is added to porcine pancreatic α-amylase (Tris-HCl buffer solution, pH 7.0, 200U / mL) Solution (mass ratio of powder to porcine pancreatic α-amylase solution 1:10), shake overnight at 37°C. After removing the starch, centrifuge at 5000 rpm and discard the supernatant. The precipitate was washed with deionized water, centrifuged at 5000 rpm, and the supernatant was discarded to collect the precipitate. After repeated washing three times, dry it for later use. Add 5g of ionic liquid [Bmim]NO to 1g of the above-mentioned medicinal dregs powder after starch removal 3 (1-butyl-3-methylimidazole nitrate), magnetically stirred at 65°C for 36 hours. After stirring and cooling, add 200 mL of deionized water, let it stand and remove the precipitate, and recover the filtrate. Concentrate the filtrate to remove water, add 50 mL of t...

Embodiment 2

[0027] After the dried Radix Astragali dregs are crushed, pass through a 100-mesh sieve, and set aside; add the above powder into porcine pancreatic α-amylase (Tris-HCl buffer, PH 7.0, 200U / mL) solution (powder and porcine pancreatic α-amylase Solution mass ratio 1:20), shake overnight at 37°C. After removing the starch, centrifuge at 5000 rpm and discard the supernatant. The precipitate was washed with deionized water, centrifuged at 5000 rpm, and the supernatant was discarded to collect the precipitate. After repeated washing three times, dry it for later use. Add 50g of ionic liquid [Bmim]NO to 5g of the above-mentioned dregs powder after starch removal 3 (1-butyl-3-methylimidazole nitrate), magnetically stirred at 90°C for 18 hours. After stirring and cooling, add 600 mL of deionized water, let it stand and remove the precipitate, and recover the filtrate. Concentrate the filtrate to remove water, add 200mL tetrahydrofuran, and let it stand to collect the precipitate, ...

Embodiment 3

[0029] After the dried Radix Astragali dregs are crushed, pass through a 100-mesh sieve, and set aside; add the above powder into porcine pancreatic α-amylase (Tris-HCl buffer, PH 7.0, 200U / mL) solution (powder and porcine pancreatic α-amylase Solution mass ratio 1:15), shake overnight at 37°C. After removing the starch, centrifuge at 5000 rpm and discard the supernatant. The precipitate was washed with deionized water, centrifuged at 5000 rpm, and the supernatant was discarded to collect the precipitate. After repeated washing three times, dry it for later use. Add 40g of ionic liquid [Bmim]NO to 3g of the above-mentioned medicinal dregs powder after starch removal 3 (1-butyl-3-methylimidazole nitrate), magnetically stirred at 70°C for 36 hours. After stirring and cooling, add 400 mL of deionized water, let it stand and remove the precipitate, and recover the filtrate. Concentrate the filtrate to remove water, add 150mL tetrahydrofuran, and let it stand to collect the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com