Drilling fluid weighting agent and preparation method thereof

A technology of weighting agent and drilling fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of oil and gas layer damage, high barite settlement rate, uneven density of drilling fluid, etc., and achieve simple preparation method , easy to popularize and apply, and avoid precipitation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

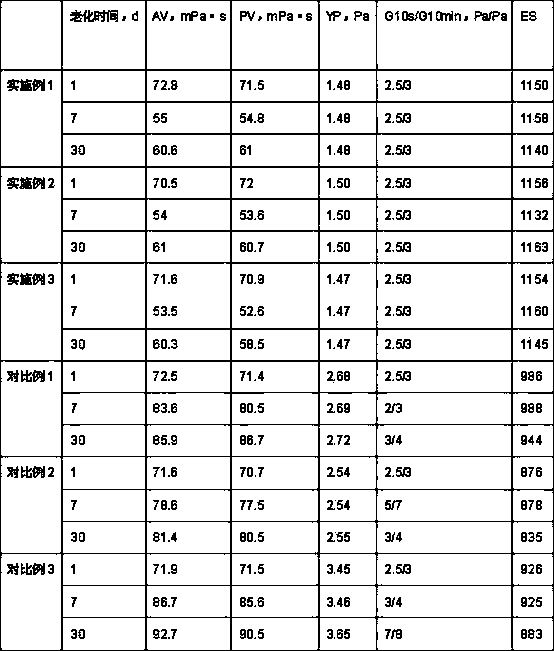

Examples

Embodiment 1

[0024] A weighting agent for drilling fluid, comprising the following components in parts by weight:

[0025] 60 parts of bauxite, 0.5 parts of lapis lazuli, 1 part of ceresite, 10 parts of silicon micropowder, 0.08 parts of cetyl ethylhexanoate, 0.2 parts of polyoxyethylene (20) sorbitan monolaurate , 0.5 parts of sodium metasilicate pentahydrate, 0.5 parts of modified attapulgite, and 20 parts of water.

[0026] The preparation method of the modified attapulgite is to soak the attapulgite with 11% sodium hydroxide for 1.5 hours, then soak it with 11% hydrochloric acid solution for 1 hour, and then wash it with deionized water to neutrality and dried to obtain modified attapulgite.

[0027] The preparation method of the weighting agent for drilling fluid in this embodiment comprises the following steps:

[0028] Step (1), pulverizing the celestite and phosphatite to 100-200 mesh to obtain celestite powder and phosphatite powder;

[0029] Step (2), add the lapis lazuli powd...

Embodiment 2

[0033] A weighting agent for drilling fluid, comprising the following components in parts by weight:

[0034] 80 parts of bauxite, 2 parts of lapis lazuli, 1.5 parts of phosphatite, 15 parts of silicon micropowder, 0.2 parts of cetyl ethylhexanoate, 0.45 parts of polyoxyethylene (20) sorbitan monolaurate , 2 parts of sodium metasilicate pentahydrate, 1 part of modified attapulgite, and 30 parts of water.

[0035] The preparation method of the modified attapulgite is to soak the attapulgite with 13% sodium hydroxide for 2 hours, then soak it with 12% hydrochloric acid solution for 3 hours, and then wash it with deionized water to neutrality and dried to obtain modified attapulgite.

[0036] The preparation method of the weighting agent for drilling fluid in this embodiment comprises the following steps:

[0037] Step (1), pulverizing the celestite and phosphatite to 100-200 mesh to obtain celestite powder and phosphatite powder;

[0038] Step (2), add the lapis lazuli powder...

Embodiment 3

[0042] A weighting agent for drilling fluid, comprising the following components in parts by weight:

[0043] 68 parts of bauxite, 0.9 parts of lapis lazuli, 1.3 parts of ceresite, 12 parts of silicon micropowder, 0.12 parts of cetyl ethylhexanoate, 0.33 parts of polyoxyethylene (20) sorbitan monolaurate , 0.14 parts of sodium metasilicate pentahydrate, 0.78 parts of modified attapulgite, and 24 parts of water.

[0044] The preparation method of the modified attapulgite is to soak the attapulgite with 12% sodium hydroxide for 1.8 hours, then soak it with 11.5% hydrochloric acid solution for 2 hours, and then wash it with deionized water to neutrality and dried to obtain modified attapulgite.

[0045] The preparation method of the weighting agent for drilling fluid in this embodiment comprises the following steps:

[0046] Step (1), pulverizing the celestite and phosphatite to 100-200 mesh to obtain celestite powder and phosphatite powder;

[0047] Step (2), add the lapis la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com