Novel drilling machine

A new type of drilling rig technology, applied in drilling equipment, earthwork drilling, support devices, etc., can solve problems such as high work experience requirements, inconvenient inflow of cutting fluid into the interior of drilling processing, unsafe operation methods, etc., to expand the depth range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below with reference to the drawings and specific embodiments.

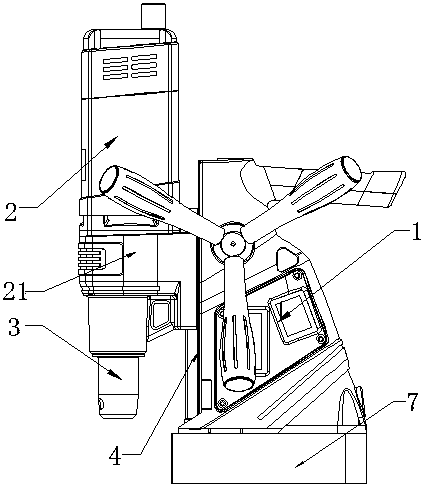

[0048] Such as figure 1 As shown, the drilling rig provided by the embodiment of the present invention includes a fixed body 1 and a machine head 2 that is perpendicular to the bottom of the machine body to move relatively back and forth. The machine head is provided with a spindle 3 for installing tools, and the spindle is installed inside the machine head. The motor is driven by a gear transmission mechanism, and the machine head is installed on the machine body through a guide rail mechanism 4.

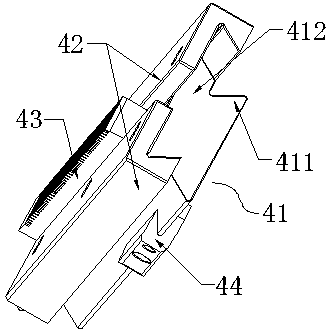

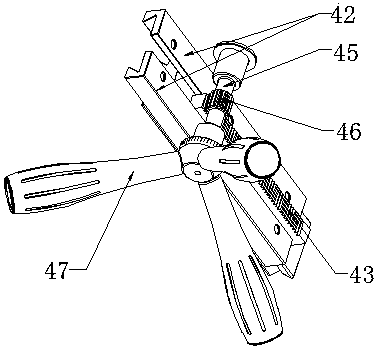

[0049] Such as figure 2 , image 3 , Figure 4 As shown, the guide rail mechanism 4 in this embodiment includes a sliding plate 41, a guide 42 and a block 44 that cooperate with each other. The guide 42 is vertically fixed on the fuselage 1, and the sliding plate 41 is provided with a first For the fixing portion 411 and the second fixing portion 412, two vertical sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com