Method for improving horizontal lateral air sending refrigeration efficiency

A refrigeration efficiency and level technology, applied in the direction of heating, space heating and ventilation, cooling/ventilation/heating transformation, etc., can solve the problems of not meeting high heat density, achieve high heat density problem, efficient and reliable operation, reduce unbalanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

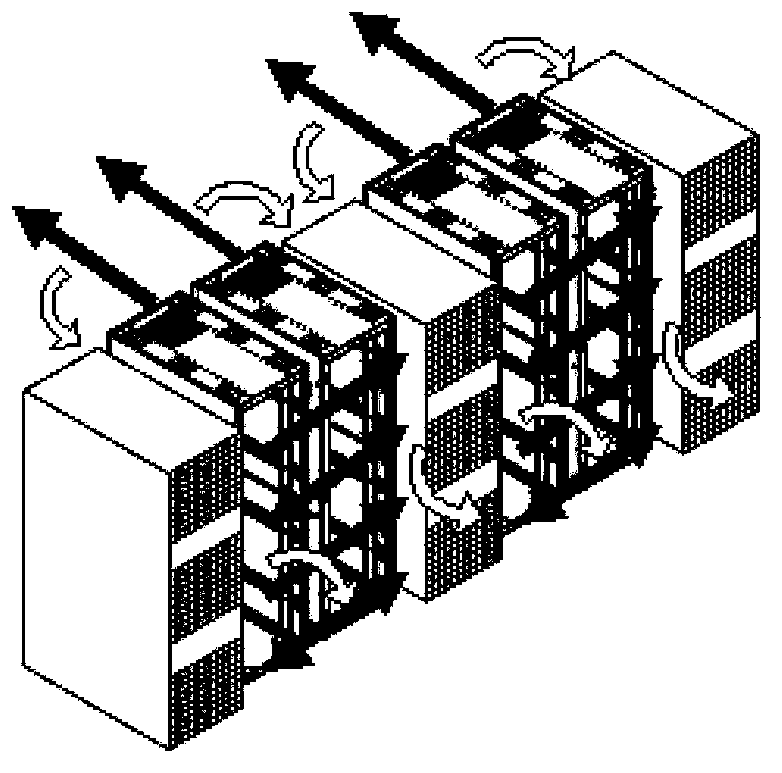

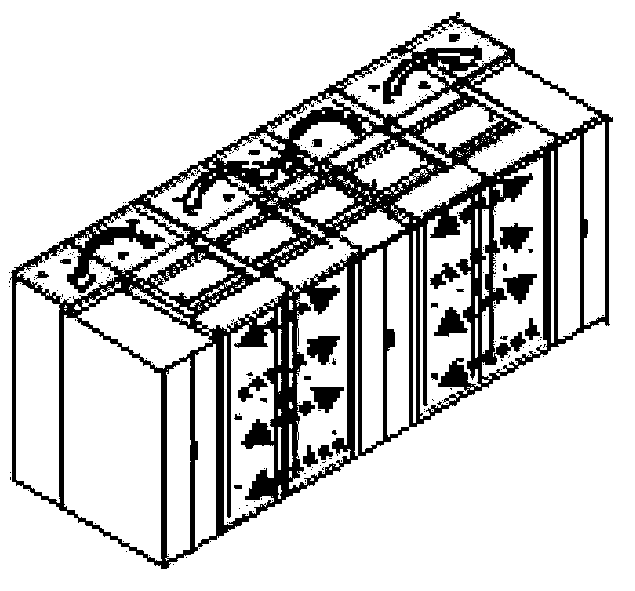

[0027] Embodiment 1: as figure 1 , figure 2 as shown,

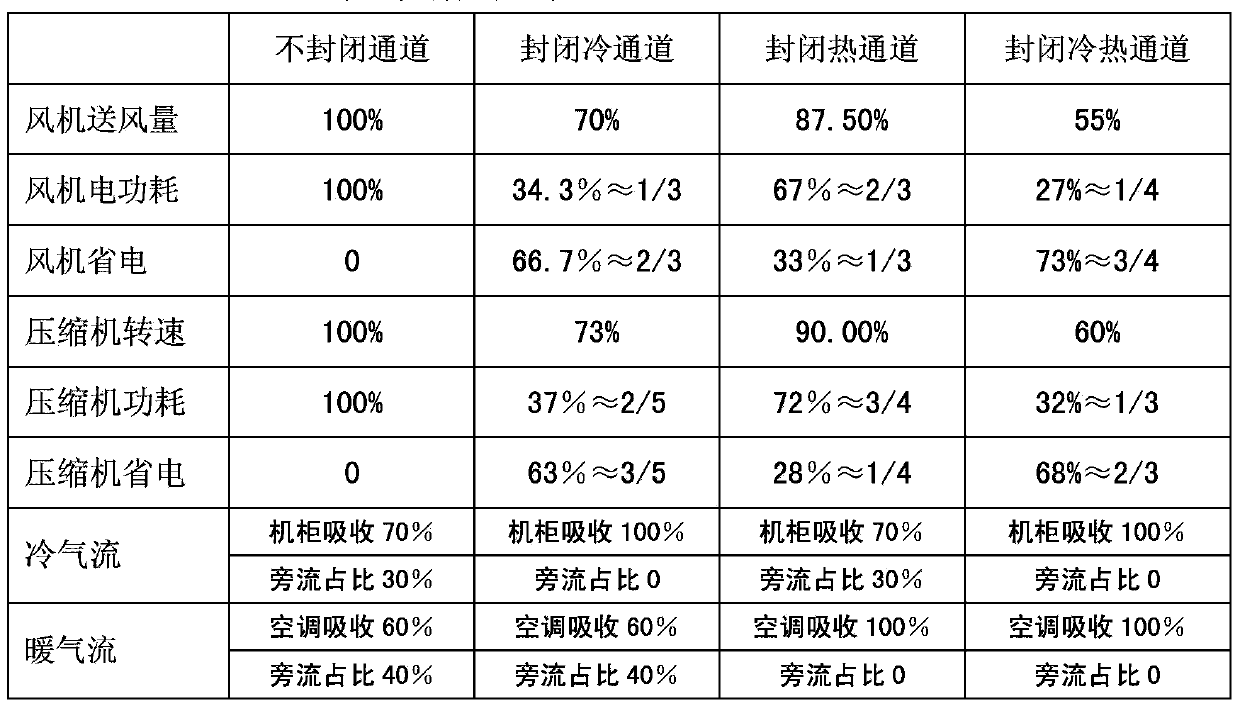

[0028] A method to improve the cooling efficiency of the horizontal side air supply. The horizontal side air supply cooling exhaust cabinet does not close the channel, which solves the problem of heat dissipation in the computer room with high heat density, but the air conditioner will still generate side flow and circulation, which will cause waste and lead to The unbalanced effect of the cooling layout of the computer room environment. Row of cabinets adopts closed components to close the cold and hot aisles. This method seals and isolates the front cold aisle and the rear hot aisle separately, which solves the problem of side flow and circulation, and avoids the impact on the environment of the computer room. Improve the efficiency of the refrigeration system and reduce the PUE value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com