Measuring head device for measuring crankshaft

A probe and crankshaft technology, applied in the field of probe devices for crankshaft measurement, can solve the problems of low measurement accuracy and efficiency, single measurement items, etc., and achieve the effects of simple structure, improved measurement accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below through the accompanying drawings and specific embodiments.

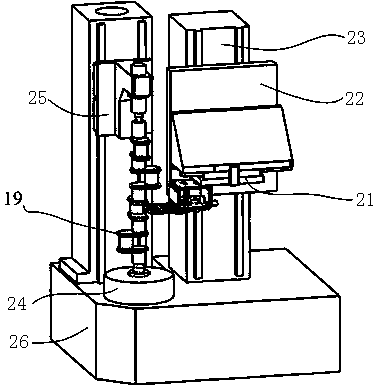

[0018] see figure 1 , the crankshaft measurement special probe device of the present invention is installed on the x-axis servo table 21 of the measuring machine, and is connected with the z-axis column 23 through the z-axis servo table 22, and the z-axis column 23 is fixed on the machine base 26, Servo turntable 24 and workpiece holder 25 are also installed on the machine base.

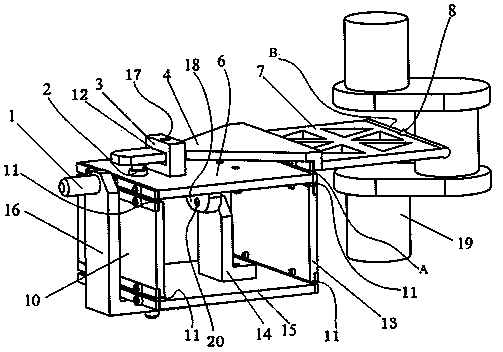

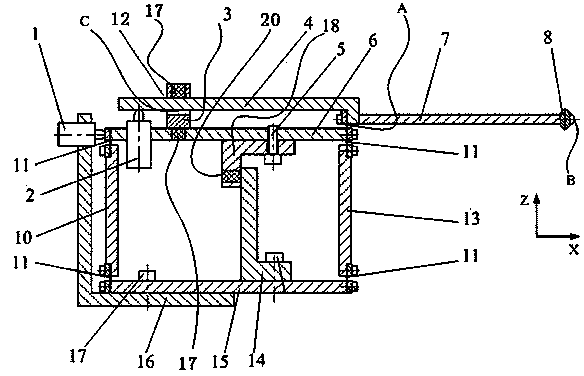

[0019] see figure 2 and image 3 , a probe device for crankshaft measurement, including an x-direction measurement assembly, a z-direction measurement assembly, and a precision reset assembly; the x-direction measurement assembly includes a flexible guide mechanism and an x-direction displacement sensor 1.1, and the flexible guide mechanism includes a spring The mobile plate 6 vertically connected successively, the left guide plate 10, the right guide plate 13 and the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com