Electric automatic control system for full-automatic supersonic nozzle high-flow standard devices

A technology of electrical automatic control and sonic nozzle, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of high cost, achieve the effects of strong debugging and simulation, high program reliability and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

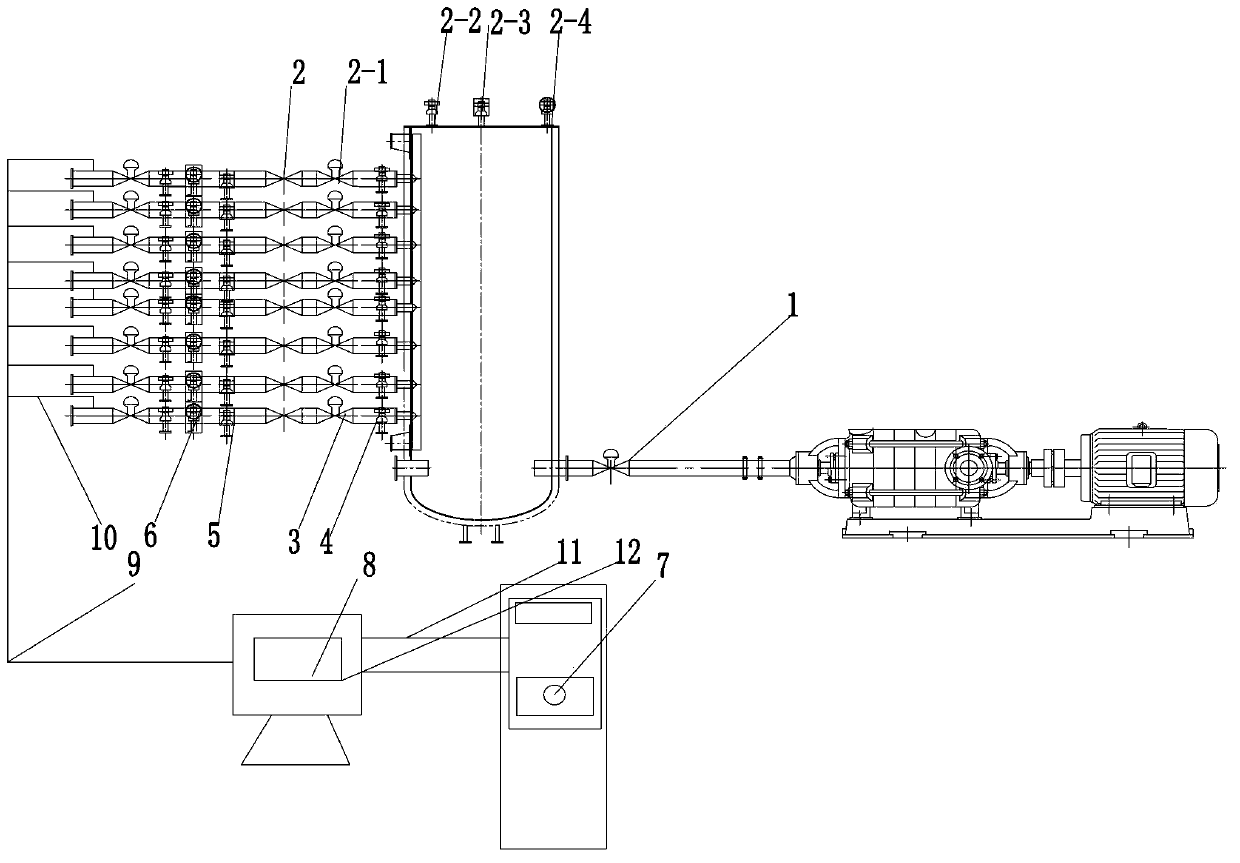

[0021] Example 1 For the composition and function of a fully automatic sonic nozzle large-flow standard device, see figure 1

[0022] The electrical automatic control system of the full-automatic sonic nozzle standard device consists of two parts: detection and control, of which the detection part is the vacuum pump regulating valve 1, the sonic nozzle control component 2, the flow regulating valve 3, the standard turbine flowmeter 4, and the differential pressure transmitter in the working section 5, temperature transmitter 6, the realization of the control part is mainly composed of PLC programmable controller 7, PC 8, PROFIBUS-DP bus 9, RS-23210 bus, RS48511 bus, monitoring software 11 and so on. The vacuum pump regulating valve 1 is used to control the jet air of the vacuum pump. The sonic nozzle assembly 2 includes 8 adjustable pneumatic valves 2-1, 1 temperature sensor 2-2, 1 pressure sensor 2-3, and 1 precision pressure gauge 2-4, which are used to control the jet a...

Embodiment 2

[0023] Embodiment 2 Working process of a fully automatic sonic nozzle large flow standard device

[0024] When the device starts to work, turn on the vacuum pump, and at the same time, the operator inputs the flow value of the meter to be measured into the host computer, and at this time, the PLC automatically opens the corresponding nozzle switch valve according to the input measurement value. Then the vacuum pump sucks the air from the inlet of the upstream straight pipe section of the meter under test, flows through the test pipe section and the flowmeter under test, enters the air storage tank, and flows through a certain combination of critical flow Venturi nozzles for buffering. When the gas device enters a stable state and the pressure before and after the nozzle reaches the critical pressure ratio, start collecting data and record it in the CPU. At the end of the test, the standard cumulative flow is calculated, and compared and calculated with the collected indicate...

Embodiment 3

[0025] Embodiment 3 Realization of control function

[0026] Data acquisition includes digital and analog acquisition: when the system enters a stable critical flow state, data acquisition can be performed by controlling the PLC system. In the gas standard device, the data is mainly collected in three channels, one of which is the analog measurement of the pressure and temperature of the gas storage tank and the meter to be tested. This data requires high real-time performance and high precision, so the PROFIBUS-DP bus and On-site temperature and pressure transmitters transmit data directly, so that the accuracy and real-time performance of the data can be guaranteed. Another channel of analog data is the pressure in the buffer tank and the meter value of the measured meter. This set of data does not require high precision, so it can be collected and converted through the analog input module AI of the PLC. The third channel of data is the digital signal of each switching va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com