4dB attenuator with 100w power capacity

A technology of power capacity and attenuation sheet, which is applied in the direction of electrical components, circuits, waveguide devices, etc., can solve problems such as increased return loss, attenuation accuracy that cannot meet the requirements, and attenuation accuracy that is difficult to control, so as to improve standing waves, Effect of improving circuit structure and optimizing power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

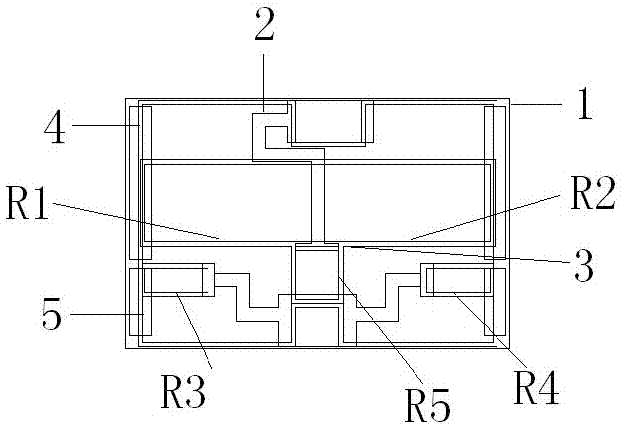

[0013] like figure 1 As shown, the 4dB attenuator with a power capacity of 100 watts includes an aluminum nitride substrate 1, and a conductive layer is printed on the back of the aluminum nitride substrate 1, and the conductive layer is printed by printing silver paste. The front side of the aluminum nitride substrate 1 is printed with resistors R1, R2, R3, R4, R5 and silver paste wires 2. The resistors R1, R2, R3, R4, and R5 connect the silver paste wires 2 to form an attenuation circuit. The resistors R1, R2 , R3, R4, and R5 are all printed with a glass protective film 3, and the glass protective film 3 is used to protect the resistors R1, R2, R3, R4, and R5. Also be printed with one deck protective film 4 on the upper surface of whole circuit i.e. silver paste conductor 2 and glass protective film 3, on protective film 4, be printed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com