Circuit board and manufacture method thereof

A circuit board production and circuit board technology, which is applied in the directions of printed circuit components, electrical connection printed components, and the formation of printed component electrical connections, can solve the problem of unfavorable dense arrangement of conductive lines and cannot meet the needs of dense conductive lines on circuit boards Requirements and other issues, to achieve the effect of dense line distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The circuit board manufacturing method provided by the technical solution includes the following steps:

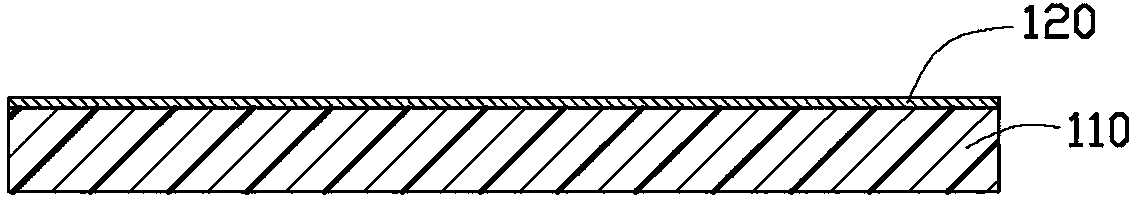

[0022] For a first step, see figure 1 , providing the carrier 110 and the first copper foil 120 .

[0023] The carrier 110 is used to support the first copper foil 120 . The first copper foil 120 is a thin copper foil, and the thickness of the first copper foil 120 is 2 microns to 5 microns. The carrier 110 is made of a metal material different from that of the first copper foil 120 or made of a non-metal material. The metal carrier 110 has sufficient mechanical strength to support the first copper foil 120 .

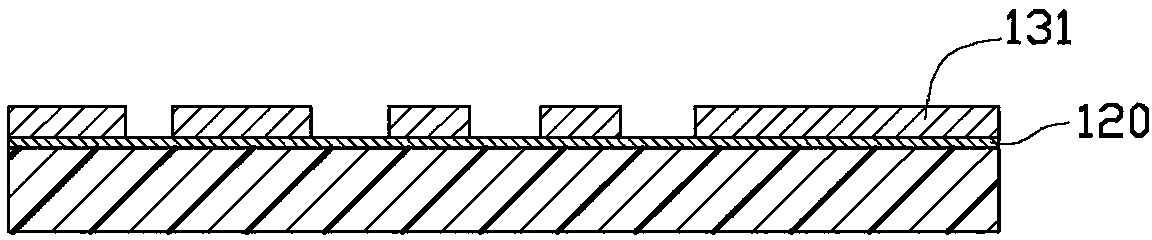

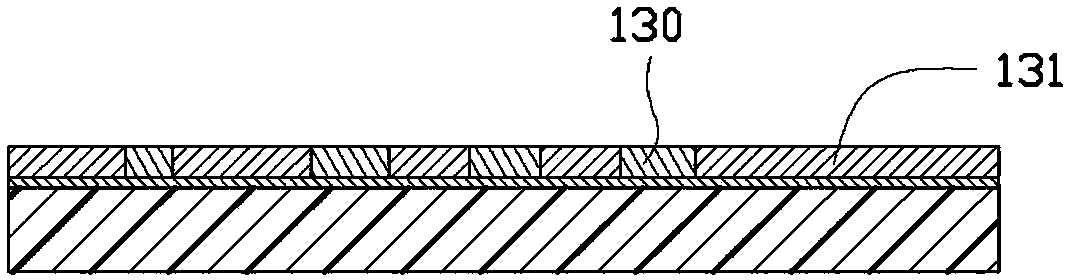

[0024] In the second step, please also refer to the Figure 2 to Figure 4 , forming the first conductive circuit layer 130 on the surface of the first copper foil 120 .

[0025] The formation of the first conductive circuit layer 130 may include the following steps:

[0026] First, a first photoresist pattern layer 131 is formed on the surface of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com