Solar cell electrode machining method and device

A solar cell and electrode processing technology, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of affecting the photoelectric conversion efficiency of solar cells, long distribution distance, large series resistance, etc., to reduce the shading area, The effect of small series resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

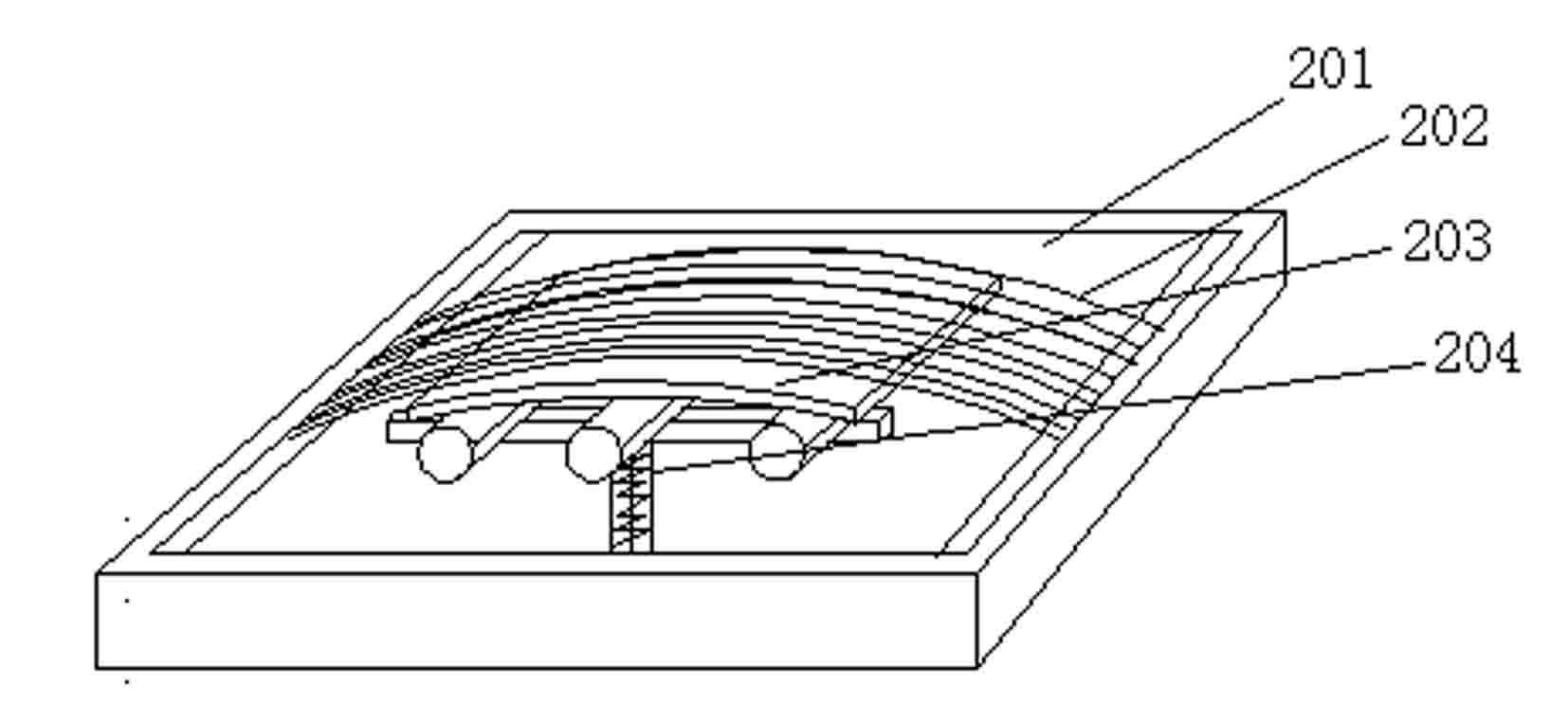

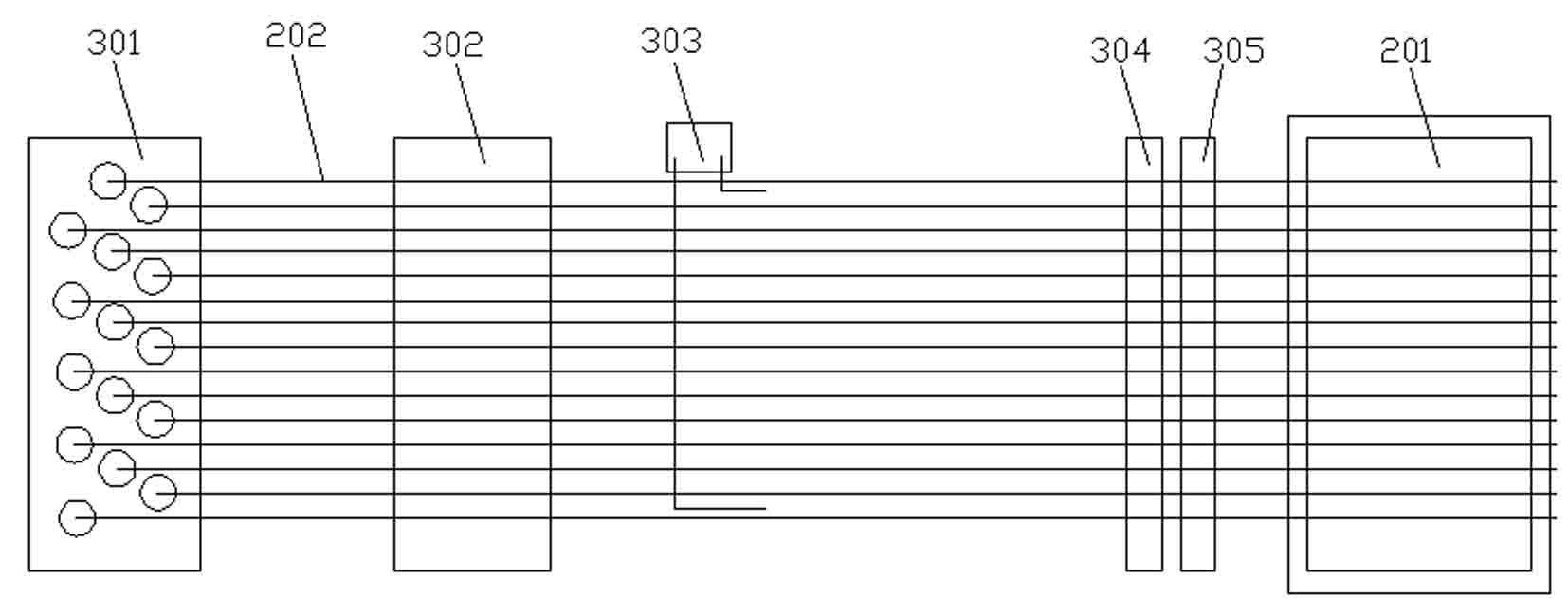

[0033] Such as Figure 1 to Figure 3 Shown, a kind of solar cell electrode processing method, it comprises the following steps:

[0034] Step 1: printing silver electrodes on the back of the solar cell 203, and then drying;

[0035] Step 2: Brush an aluminum electric field on the back of the solar cell 203 printed with silver electrodes, and then dry it;

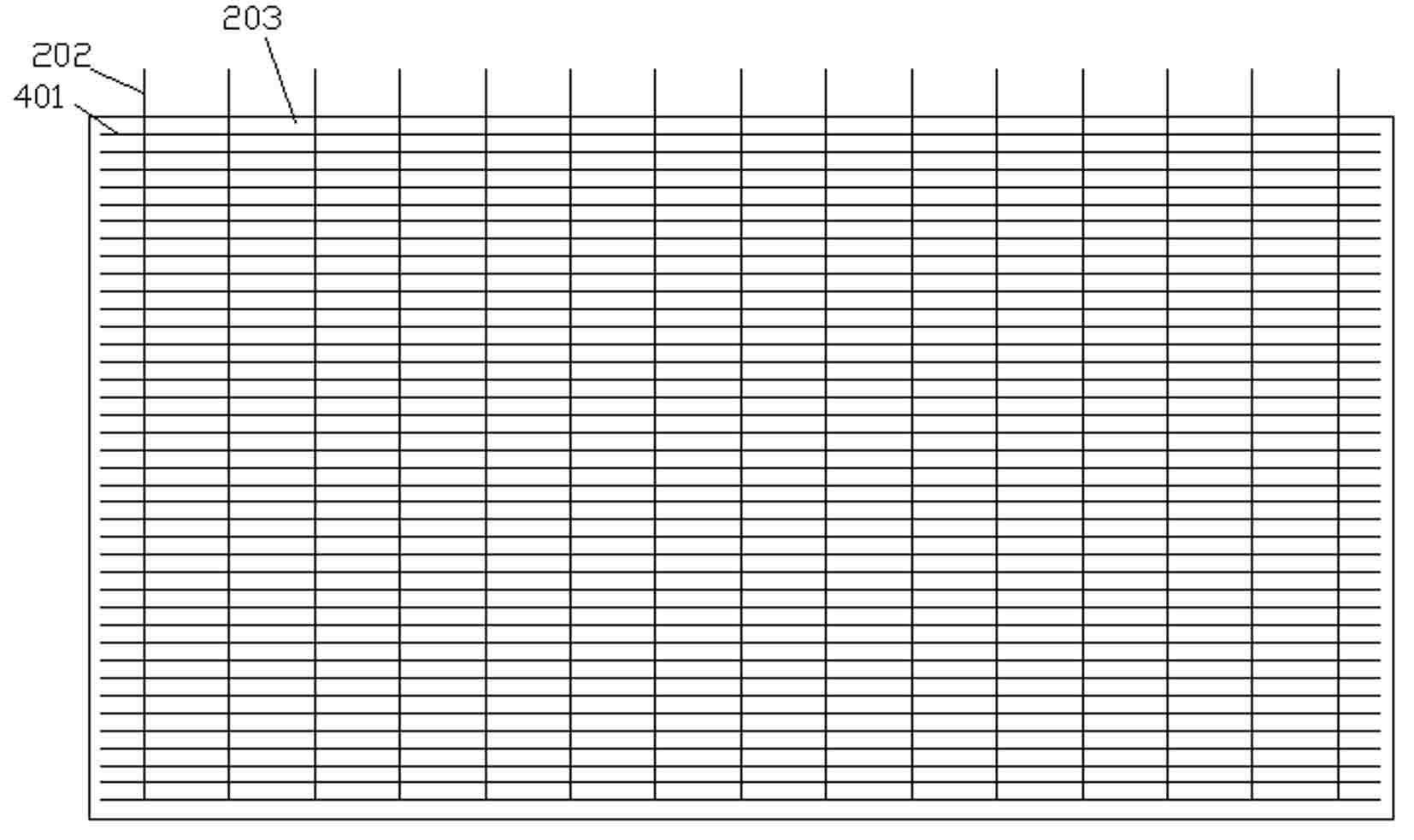

[0036] Step 3: printing horizontal silver grid lines 401 on the front side of the solar cell 203;

[0037] Step 4: The manipulator places the solar cell that has completed the above steps on the jacking mechanism 204, and places it in the center;

[0038] Step 5: The clamping mechanism 201 intercepts the resistance wire 202 dipped in silver paste from the autom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com