Main gate-free, high-efficiency and back-contact solar battery backplane, assembly and preparation process

A solar cell, high-efficiency technology, applied in the field of solar cells, can solve the problems of difficulty in precise punching, easy leakage, and decreased filling factor, and achieve the effects of eliminating shading loss, increasing contact area, and improving cell efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

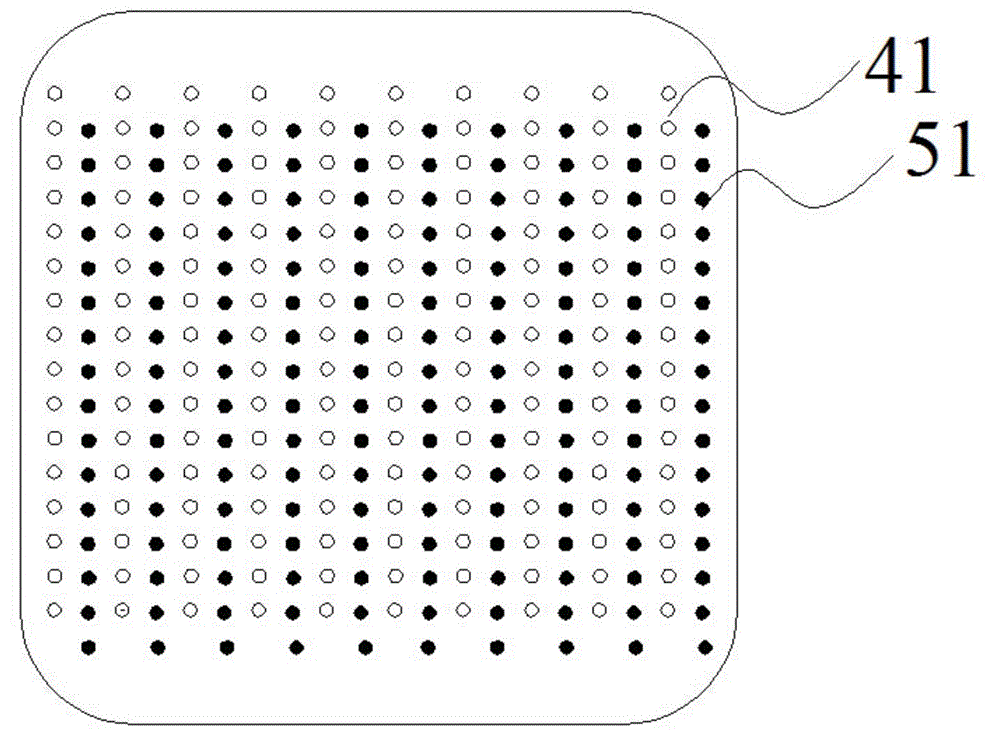

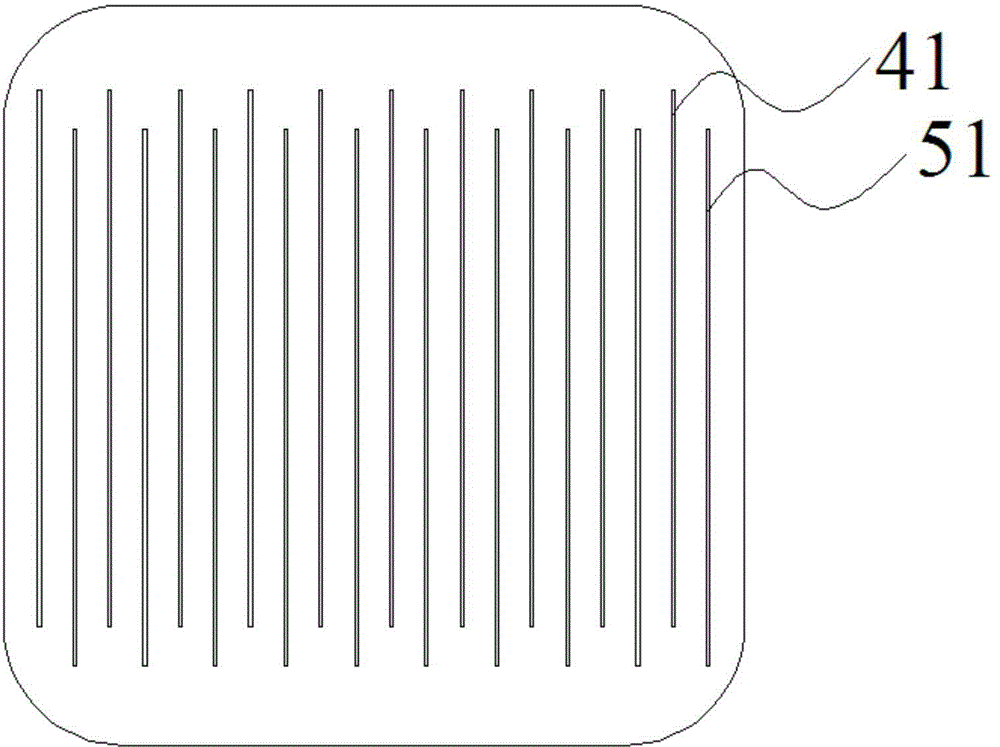

[0069] Such as Image 6 As shown, a busbar-free high-efficiency back-contact solar cell backsheet 8 includes an electrical connection layer and a base layer 82, and the electrical connection layer 81 and the base layer 82 are connected by an adhesive; the electrical connection layer 81 includes conductive wires 11, The insulated wires 12 , the conductive wires 11 and the insulated wires 12 are braided to form a mesh structure, and the insulated wires 12 are braided between adjacent conductive wires 11 . The solar battery backplane 8 has a width of 651mm and a length of 662mm.

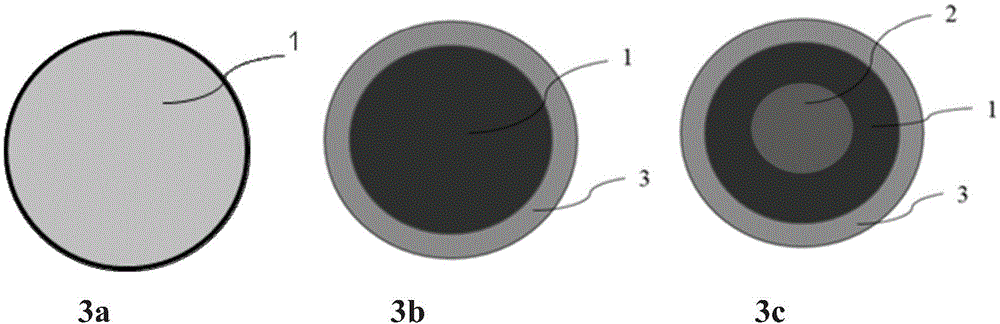

[0070] Such as Figure 8 As shown, a solar cell module comprising the above-mentioned busbar-free high-efficiency back-contact solar cell backsheet 8 includes a front layer material 13, a solar cell layer 10, and a backsheet 8 connected from top to bottom, wherein the solar cell layer 10 includes several cells, such as figure 1 As shown, a P electrode connected to the P-type doped layer 5 and an N el...

Embodiment 2

[0077] Such as Image 6 As shown, a busbar-free high-efficiency back-contact solar cell backsheet 8 includes an electrical connection layer 81 and a base layer 82, and the electrical connection layer 81 and the base layer 82 are connected by an adhesive; the electrical connection layer 81 includes conductive wires 11 1. Insulated wires 12, the conductive wires 11 and the insulated wires 12 form a mesh structure through weaving, and the insulated wires 12 are braided between adjacent conductive wires 11. The solar battery backplane 8 has a width of 986mm and a length of 1662mm.

[0078] Such as Figure 8 As shown, a solar cell module comprising the above-mentioned busbar-free high-efficiency back-contact solar cell backsheet 8 includes a front layer material 13, a solar cell layer 10, and a backsheet 8 connected from top to bottom, wherein the solar cell layer Including several battery slices, such as figure 1 As shown, a P electrode connected to the P-type doped layer 5 and...

Embodiment 3

[0087] Such as Image 6As shown, a busbar-free high-efficiency back-contact solar cell backsheet 8 includes an electrical connection layer 81 and a base layer 82, and the electrical connection layer 81 and the base layer 82 are connected by an adhesive; the electrical connection layer 81 includes conductive wires 11 1. Insulated wires 12, the conductive wires 11 and the insulated wires 12 form a mesh structure through weaving, and the insulated wires 12 are braided between adjacent conductive wires 11. The solar battery backplane 8 has a width of 651mm and a length of 662mm.

[0088] Such as Figure 9 As shown, a solar cell module comprising the above-mentioned busbar-free high-efficiency back-contact solar cell backsheet 8 includes a front layer material 13, a solar cell layer 10, and a backsheet 8 connected from top to bottom, wherein the solar cell layer 10 includes several cells, such as figure 2 As shown, the battery sheet includes an N-type monocrystalline silicon su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com