Wiring board

A technology of wiring substrates and insulating substrates, which is applied to the layout details of conductive patterns, printed circuits, printed circuits connected with non-printed electrical components, etc., can solve problems such as cracks, and achieve the effect of improving joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

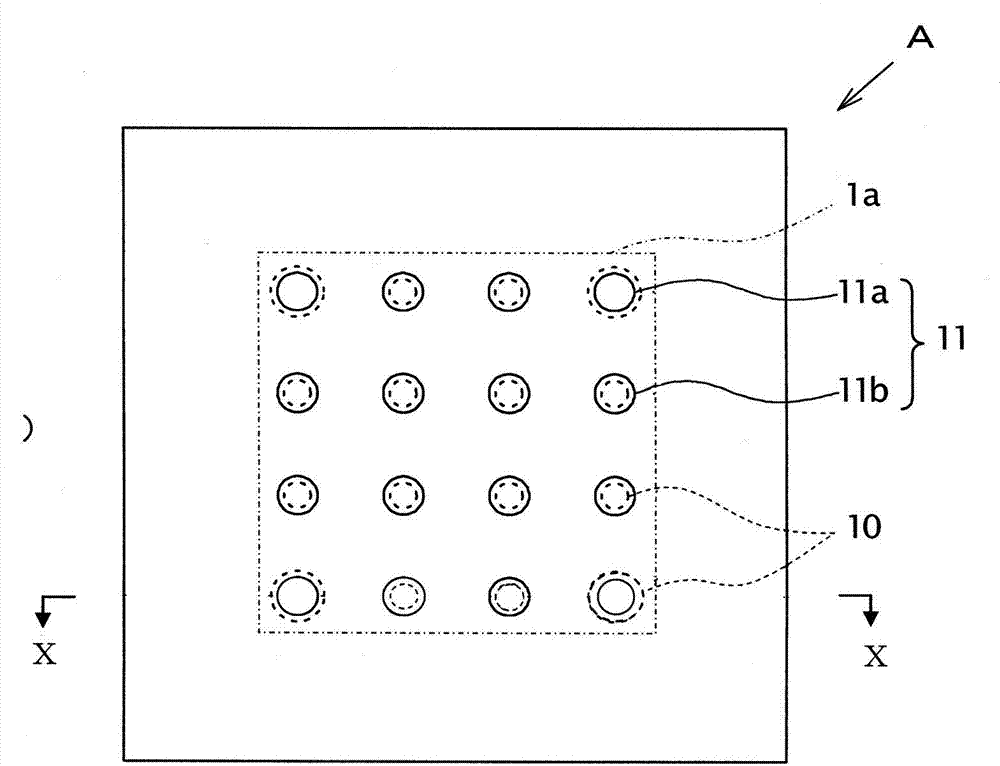

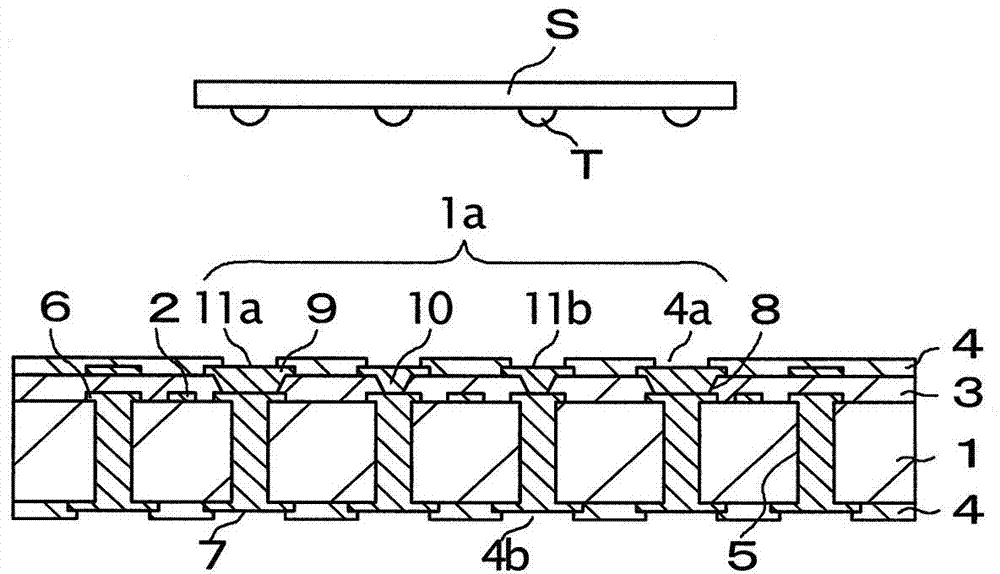

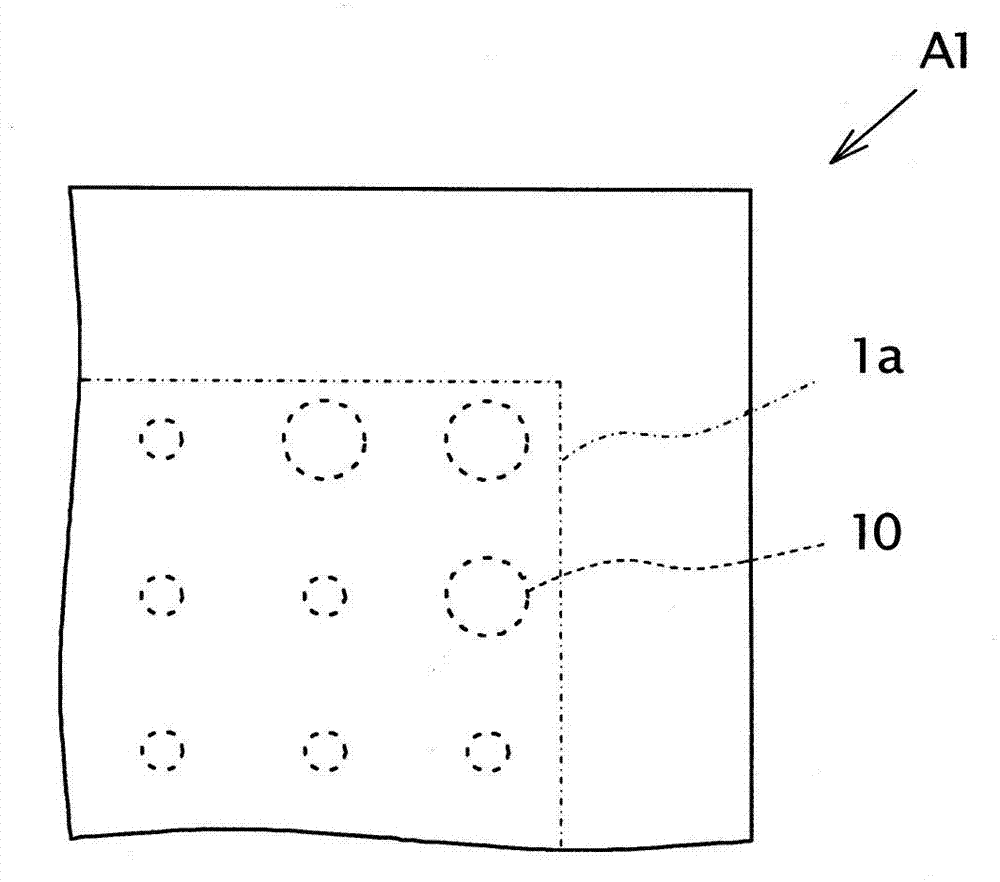

[0043] Next, an embodiment of a wiring board in the first aspect of the present invention will be described based on FIG. 1 . Figure 1A is a schematic plan view of the wiring board A, Figure 1B yes Figure 1A XX-line side cross-sectional view. Such as Figure 1B As shown, the wiring board A includes an insulating substrate 1 , a wiring conductor 2 , an insulating layer 3 , and a solder resist layer 4 . In the central portion of the upper surface of the wiring board A, for example, a semiconductor element mounting portion 1 a for mounting a large semiconductor element S for arithmetic processing or the like is formed in a quadrangular shape.

[0044] The insulating substrate 1 is made of, for example, glass-epoxy resin. A plurality of through holes 5 penetrating from the upper surface toward the lower surface are formed in the insulating substrate 1 . Part of the wiring conductor 2 is covered on the upper and lower surfaces of the insulating substrate 1 and the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com