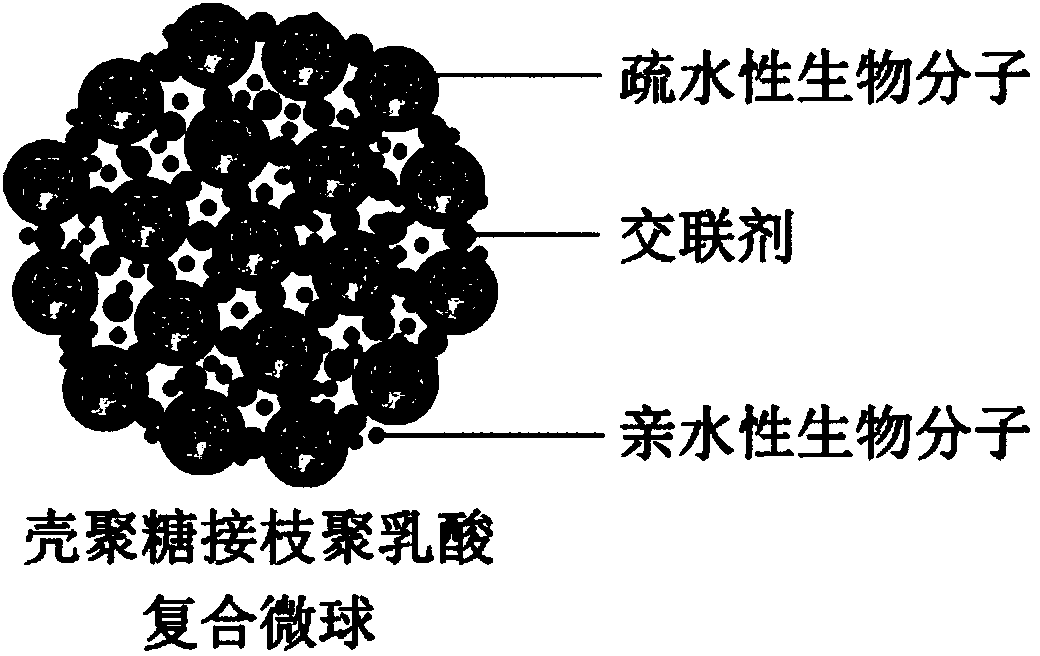

Chitosan grafted polylactic acid composite microsphere simultaneously carried with hydrophilic and hydrophobic biological molecules and preparation method of chitosan grafted polylactic acid composite microsphere

A technology of biomolecules and composite microspheres, which is applied in the field of functionalized polymer microspheres and drug controlled release, and biomedical materials, can solve the problems of not being able to dissolve solvents at the same time, chitosan and polylactic acid have too much difference in hydrophilic and hydrophobic properties, High glass transition temperature etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Chitosan-grafted polylactic acid composite microspheres loaded with hydrophobic biomolecules

[0026] Weigh 1.0 g of chitosan-grafted polylactic acid and dissolve it in 10 ml of dimethyl sulfoxide, and add 10 mg of the steroid hormone fluocinolone. After being completely dissolved, the obtained solution was transferred to a dialysis bag with a molecular weight cut-off of 6-8 kilodaltons, and dialyzed at room temperature for 24 hours, and the deionized water was replaced every 6 hours to obtain chitosan coated with fluocinolone. Sugar-grafted polylactic acid core-shell micelles solution. The micellar solution is concentrated to a concentration of 3% (mass volume ratio), and under the effect of mechanical stirring, it is added dropwise to 100 milliliters of mineral oil containing 2% (mass volume ratio) Span 80 to form water-in-oil mixed emulsion. Add 2.5 grams of sodium tripolyphosphate solution with a concentration of 10% (mass volume ratio) to the mixed emu...

Embodiment 2

[0027] Example 2: Chitosan-grafted polylactic acid composite microspheres loaded with hydrophobic biomolecules

[0028] Weigh 1.0 g of chitosan-grafted polylactic acid and dissolve it in 10 ml of dimethyl sulfoxide, and add 10 mg of anticancer drug paclitaxel. After being completely dissolved, the resulting solution was transferred to a dialysis bag with a molecular weight cut-off of 6-8 kilodaltons, dialyzed at room temperature for 24 hours, and deionized water was replaced every 6 hours to obtain paclitaxel-coated chitosan Grafted polylactic acid core-shell micellar solution. The micellar solution is concentrated to a concentration of 3% (mass volume ratio), and under the effect of mechanical stirring, it is added dropwise to 100 milliliters of mineral oil containing 2% (mass volume ratio) Span 80 to form water-in-oil mixed emulsion. Add 2.5 grams of sodium tripolyphosphate solution with a concentration of 10% (mass volume ratio) to the mixed emulsion, and continue to stir...

Embodiment 3

[0029] Example 3: Chitosan-grafted polylactic acid composite microspheres loaded with hydrophilic biomolecules

[0030] Weigh 1.0 g of chitosan-grafted polylactic acid and dissolve it in 10 ml of dimethyl sulfoxide. After being completely dissolved, the obtained solution was transferred to a dialysis bag with a molecular weight cut-off of 6 to 8 kilodaltons, and was dialyzed at room temperature for 24 hours, and the deionized water was replaced every 6 hours to obtain chitosan grafted polysaccharides. Core-shell micellar solution of lactic acid. Concentrating the micellar solution to a concentration of 3% (mass volume ratio), adding 10 mg of growth factor bone morphogenetic protein 2, under the effect of mechanical stirring, it was added dropwise to 100 milliliters containing 2% (mass volume ratio) In mineral oil of class 80, a water-in-oil mixed emulsion is formed. Add 2.5 grams of sodium tripolyphosphate solution with a concentration of 10% (mass volume ratio) to the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com