Automatic Backwash Combined Filter

A backwashing and filter technology, which is applied in the direction of fixed filter element filter, filter separation, filter circuit, etc., can solve the problems that affect the normal operation of the host equipment, large equipment space, difficult gas discharge, etc., and achieve the effect of overcoming technical wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

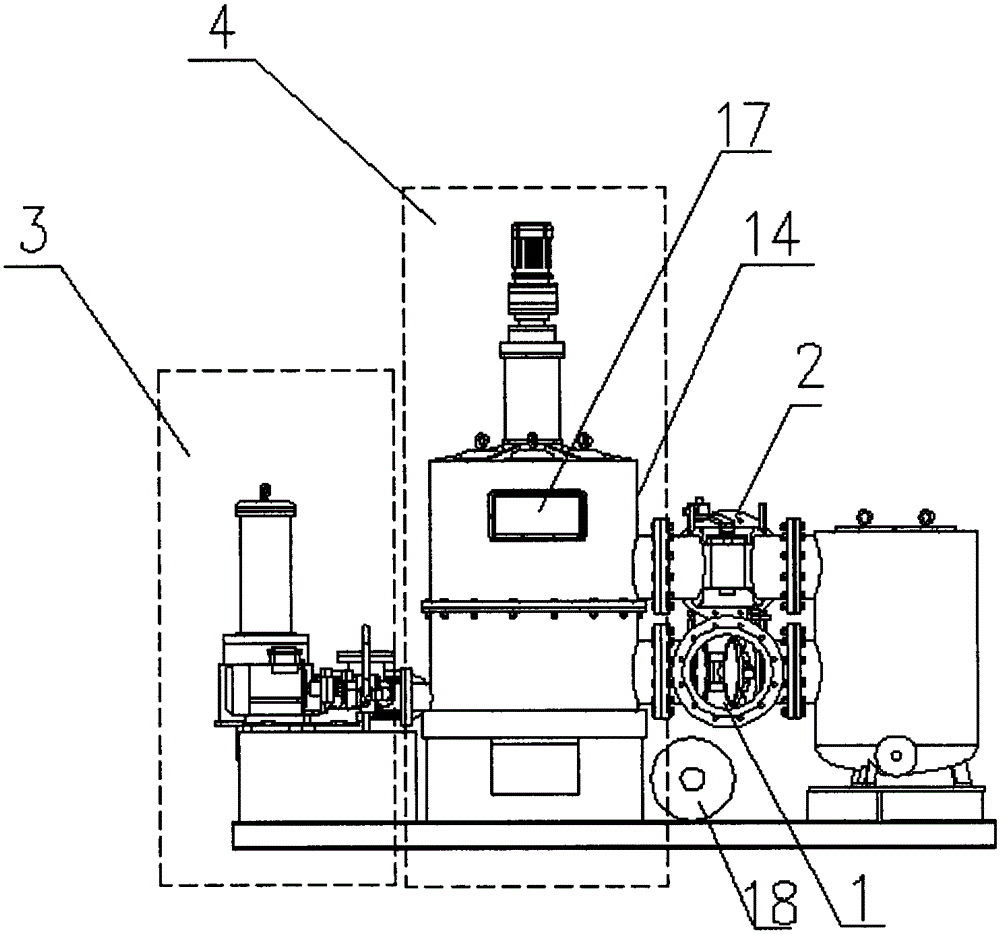

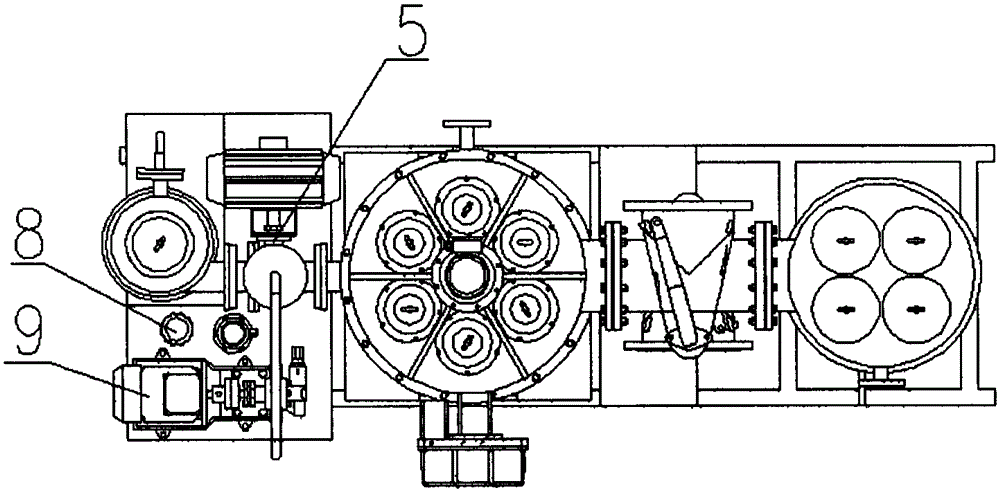

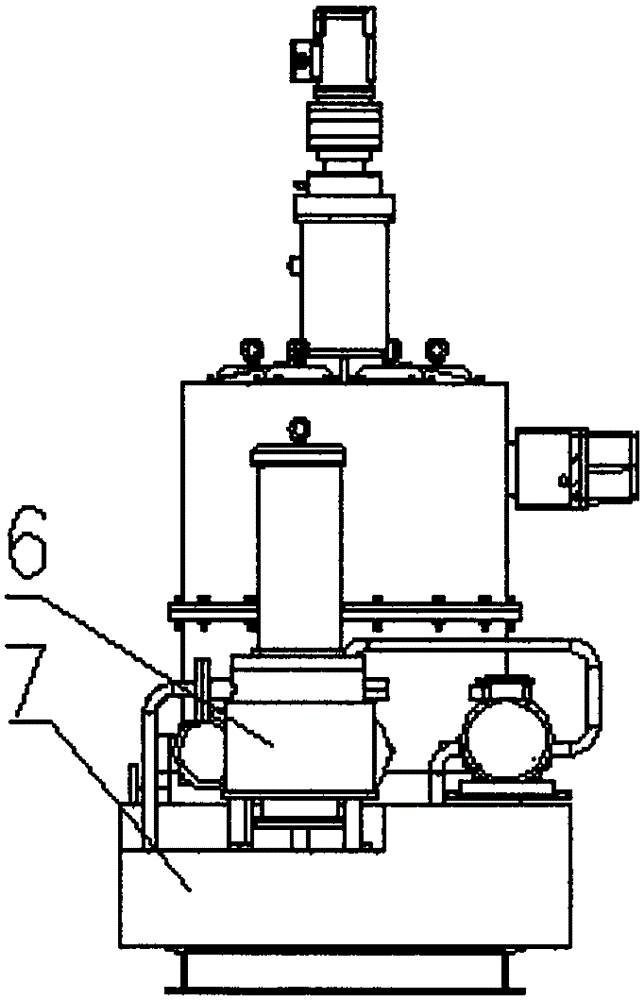

[0019] Such as figure 1 , 2 As shown in , 3 and 4, an automatic backwash combined filter includes a filter liquid inlet 1, a filter liquid outlet 2, an oil return pump oil replenishment device 3 and a backwash filter device 4, a filter liquid outlet 2 and a filter liquid inlet 1 The upper and lower parallel arrangements are connected with the recoil filter device 3. The oil return and replenishment device 3 of the oil transfer pump includes a pneumatic three-way valve 5, a dirty oil chamber 6, an oil tank 7, an air filter 8 and an oil transfer pump 9. The inlet direction of the oil tank 7 is connected with a dirty The oil outlet of the oil chamber 6 and the outlet direction of the oil tank 7 are connected to one end of the oil delivery pump 9 through a pipeline, the other end of the oil delivery pump 9 is connected to one end of the pneumatic three-way valve 5, and the other two ends of the pneumatic three-way valve 5 are respectively connected to There is an oil inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com