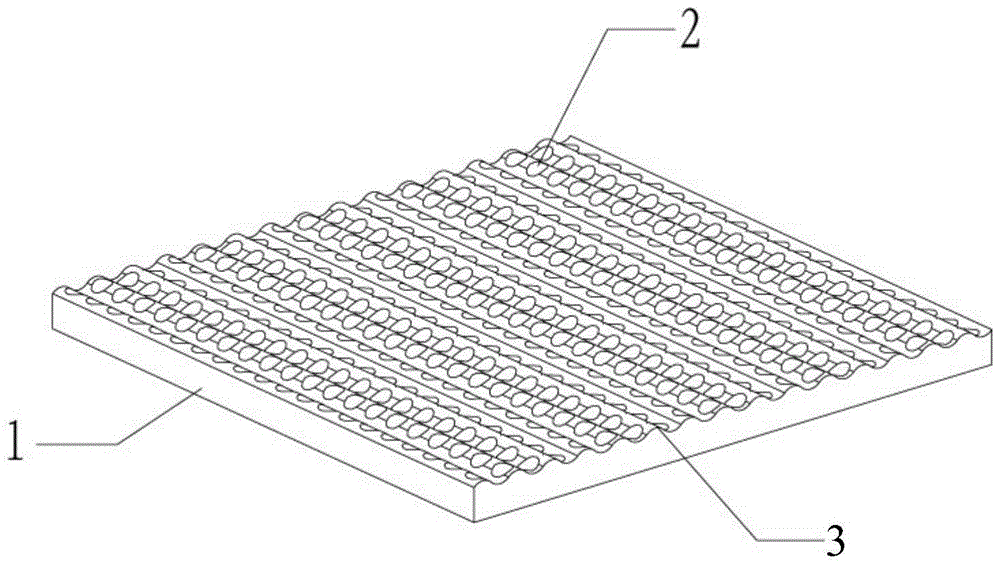

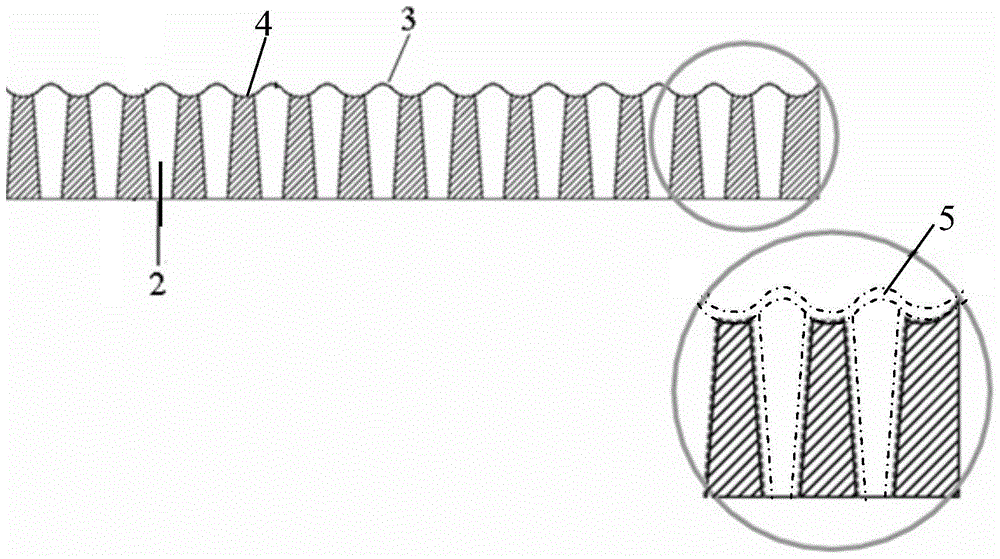

Preparation Technology of Nanometer TiO2 Photocatalyst Thin Film

A nano-titanium dioxide and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of insufficient photocatalyst adhesion, insufficient adhesion, short service life, etc., and achieve shortened removal time, high formaldehyde removal rate, and reduced raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of preparation technology of nano titanium dioxide photocatalyst film, comprises the following steps:

[0046] Step 1. Put 5 grams of metal titanium into a 500 ml glass beaker, add 85 ml of hydrogen peroxide aqueous solution, the molar ratio of metal titanium to hydrogen peroxide is 1:8, and the metal titanium is granular sponge titanium;

[0047] Step 2, place the glass beaker in an ice-water bath, the temperature of the ice-water bath is controlled at about 10°C, and the mixed solution is stirred at a medium speed to form an intermediate reactant;

[0048] Step 3: Pour 75ml of ammonia water into a 500ml flask with a branch pipe and a piston, place the flask in a temperature-controlled hot water bath at about 60°C, heat the ammonia to form ammonia vapor, and the ammonia vapor enters the medium-speed stirring tank through the branch pipe In the intermediate reactant, when the pH value of the intermediate reactant reaches about 9, close the piston on...

Embodiment 2

[0061] Embodiment 2: a kind of preparation technology of nano titanium dioxide photocatalyst film, comprises the following steps:

[0062] Step 1. Put 5 grams of metallic titanium into a glass beaker, add 107 mL of hydrogen peroxide aqueous solution to form a mixed solution, the molar ratio of metallic titanium to hydrogen peroxide is 1:10, and the metallic titanium is granular sponge titanium;

[0063] Step 2, place the glass beaker in an ice-water bath, the temperature of the ice-water bath is controlled at about 12°C, and stir the mixed solution at a medium speed to form an intermediate reactant;

[0064] Step 3: Pour 91mL of ammonia water into a flask with a branch pipe and a piston, place the flask in a hot water bath, control the temperature of the water bath at about 60°C, and heat to volatilize the ammonia to form ammonia vapor, which enters the intermediate reaction through the branch pipe In the product, adjust the pH value of the intermediate reactant to the range o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com