Power station boiler make-up water system mixed bed regeneration method

A power plant boiler and supply water technology, applied in ion exchange regeneration, chemical instruments and methods, ion exchange water/sewage treatment, etc., can solve the problems of increased acid and alkali consumption, dry resin of anion resin, incomplete regeneration of anion resin, etc. problems, to achieve the effect of reducing acid consumption and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

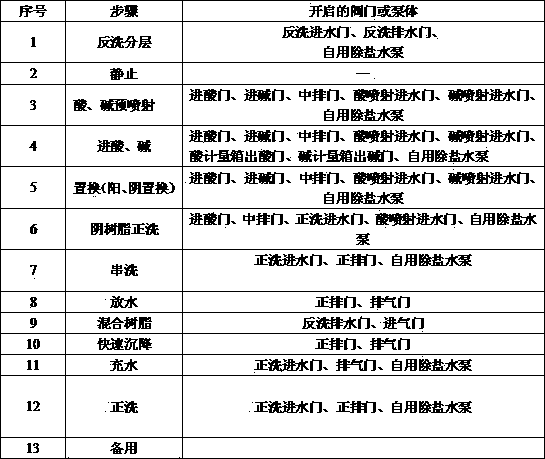

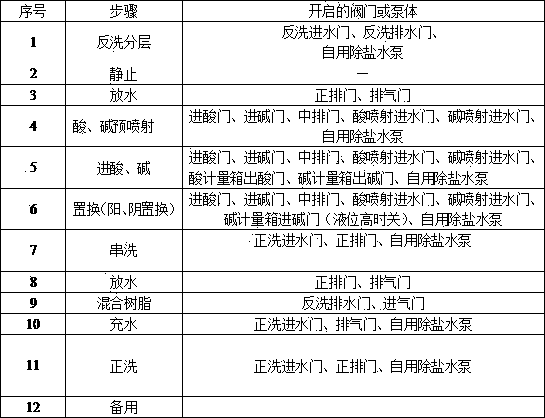

[0038] Improve the regeneration procedure, cancel the "water release" step, and change it to the full tank regeneration method. After "acid, alkali" and "replacement", add "anion resin positive washing" to ensure the regeneration effect; in the "mixed resin" step Finally, add the step of "rapid sedimentation" to prevent the re-separation of the mixed resin. The improved automatic control program is shown in Table 2.

[0039] Table 2 Sequence of regeneration steps of the improved mixed bed

[0040]

[0041] Beneficial effect: With the new regeneration procedure, the mixed bed can be successfully regenerated at one time, and the automatic regeneration can be truly realized, which saves a lot of human resources, reduces acid consumption and alkali consumption, and is of great significance to the energy saving and emission reduction of the power station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com