Mixed Sugar Granular Powder And Method For Preparing Same

A technology of mixing sugar and powder, which is applied in sugar products, sugar production, sucrose production, etc. It can solve the problems of poor convenience, uneven mixing and re-separation, and difficulty in keeping allulose in powder state, so as to achieve dispersibility and Improvement of fluidity, improvement of physical properties, and improvement of sweetness quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0066] Preparation Example 1: Preparation of Allulose

[0067] 1-1: Preparation of a psicose-producing strain

[0068] Synthesis of the gene encoding psicose epimerase (DPE gene; GenBank: EDS06411.1) derived from Clostridium flickering bacteria (Clostridium flickering ATCC 35704) as a modified form of polynucleotide optimized for Escherichia coli And known as CDPE. The polynucleotide optimized for Escherichia coli (SEQ ID NO: 2) and the sod promoter and the T7 terminator obtained from the pET21a vector were obtained by PCR as respective templates, and they were connected as a template by overlapping PCR method, and passed T Vector cloning It was cloned into the pGEM T-easy vector, thereby confirming the sod promoter (SEQ ID NO: 1), the optimized CDPE sequence (SEQ ID NO: 8) and the polynucleotide sequence containing the T7 terminator.

[0069] Using the restriction enzymes NotI and XbaI (NEB), all confirmed polynucleotides were inserted into the same restriction sites of t...

Embodiment 1

[0087] Example 1: Preparation of mixed granules of allulose and glucose

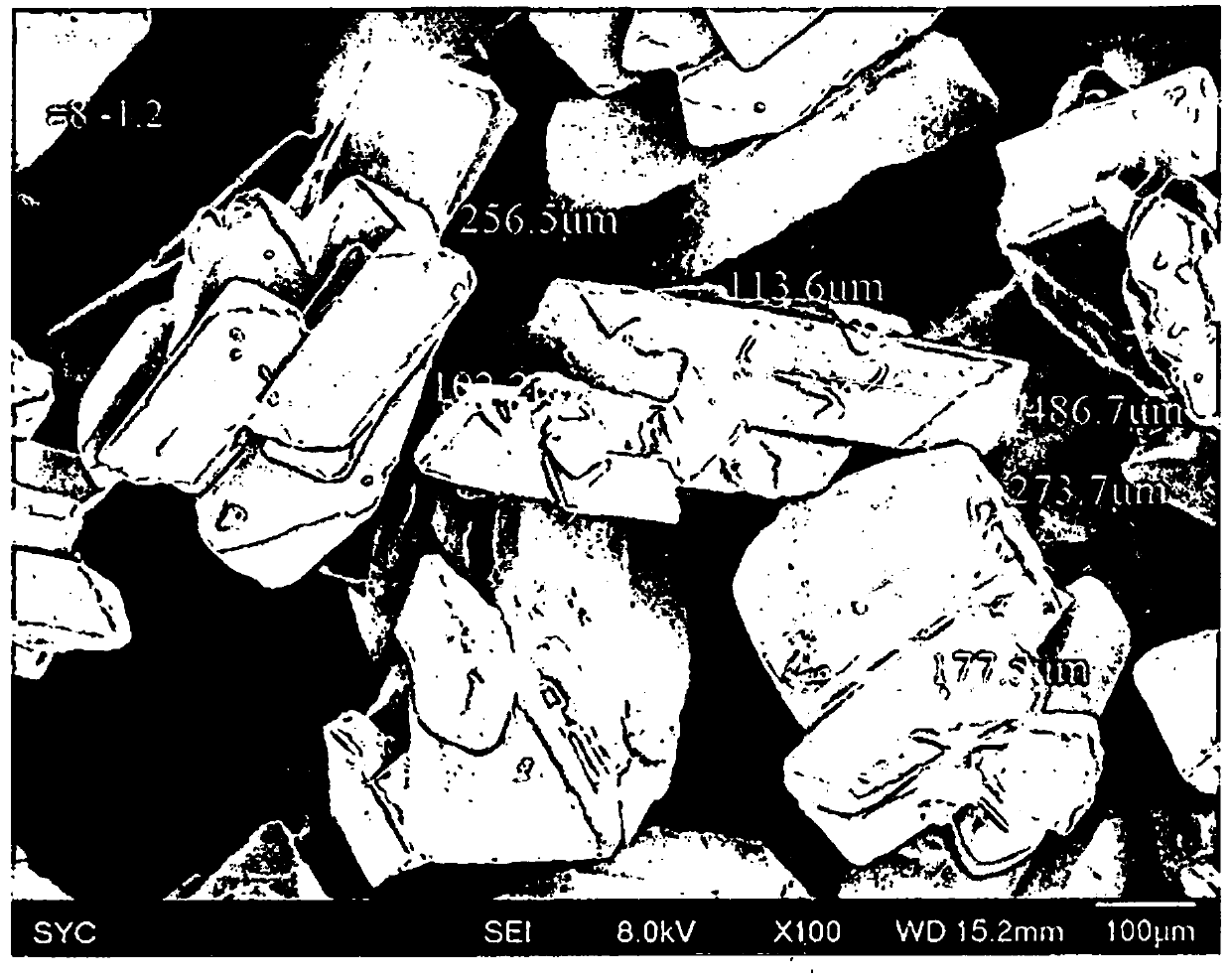

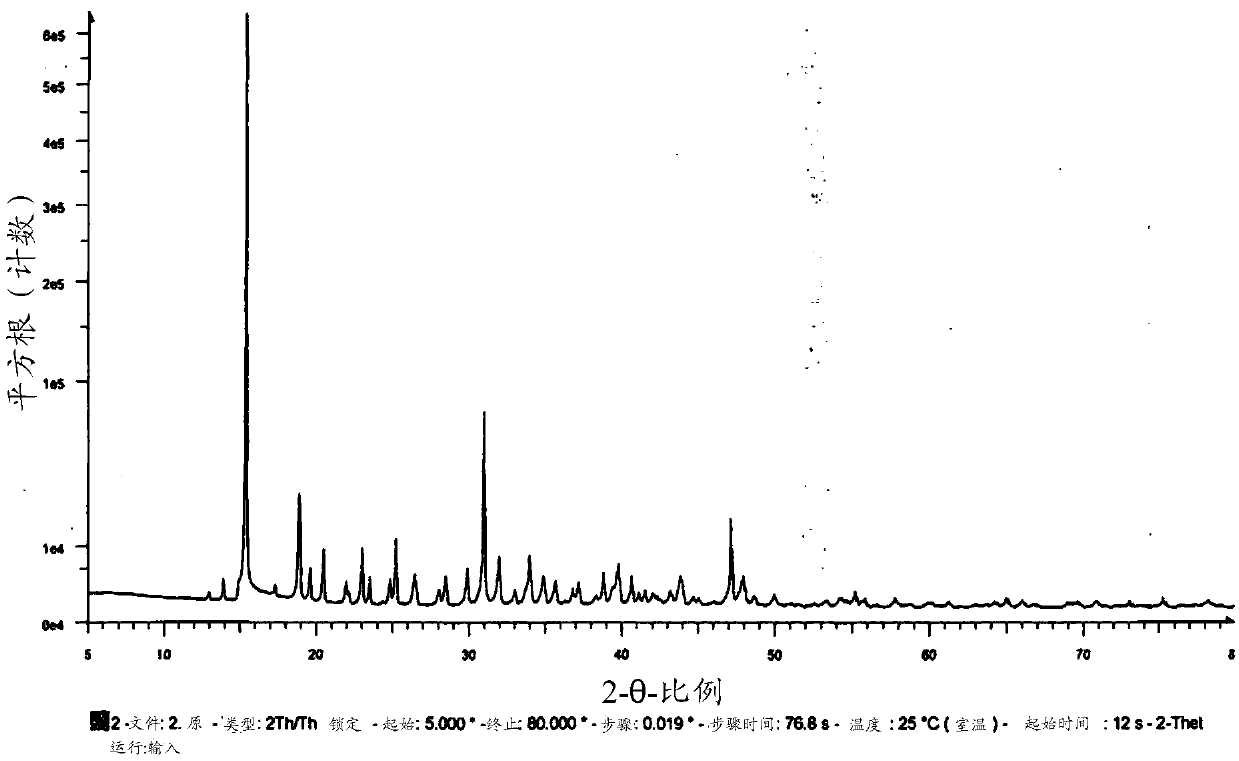

[0088] 1-1: Using anhydrous glucose with an average particle size of 295 μm

[0089] After mixing 150 g of each psicose powder prepared in Preparation Examples 1-3 with anhydrous glucose powder having an average particle size of 295 μm at a weight ratio (w / w) of 1:1, the powder-introduction condition was set as Input temperature 50°C, output temperature 40°C and air pressure 30m 2 / h fluidized bed granulation dryer (FBS, Germany manufacturing), thereby preparing granules and drying. At this time, in order to form particles well, the binding solution was sprayed at a rate of 10 rpm for 15 minutes in an amount of 10 to 20% of the total weight of the total mixed powder, wherein the purity of fermented alcohol was 95% or higher. The advantage of alcohol is that it volatilizes when spraying and does not exist in the powder, so it does not affect the content. When all the alcohol had been sprayed, the i...

Embodiment 2

[0092] Example 2: Preparation of mixed granules of psicose and sugar

[0093] 2-1: Using powdered sugar with an average particle size of 72 μm

[0094] 150 g of each psicose powder prepared in Preparation Examples 1-3 and powdered sugar having an average particle size of 72 μm (which was prepared by grinding sugar and disclosed in Table 1) were mixed at a ratio of 1:1 (w / w). After proportional mixing, granular powder was prepared in the same manner as in Example 1.

[0095] 2-2: Superfine granulated sugar with an average particle size of 230 μm is used

[0096] After mixing 150 g of each of the allulose powders prepared in Preparation Examples 1-3 with superfine granulated sugar (caster sugar) with an average particle size of 230 μm at a ratio of 1:1 (w / w), the same method as in Example 1 was used. way to prepare granular powder.

[0097] 2-3: Use fine granulated sugar with an average particle size of 392 μm

[0098] After mixing 150 g of each of the allulose powders p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com