Energy-saving vibration sieve

A technology of vibrating screen and screen body, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high motor cost, large screen load loss, large impact on production efficiency, etc., to reduce structural strength requirements, reduce Force demand, the effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

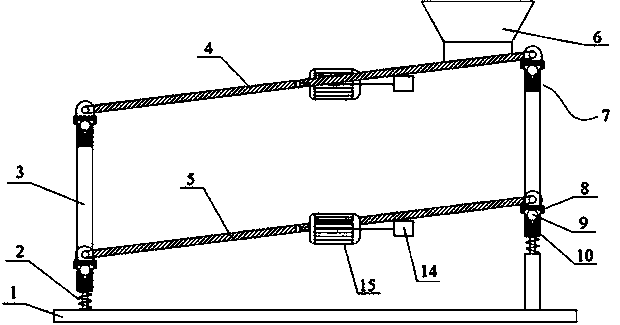

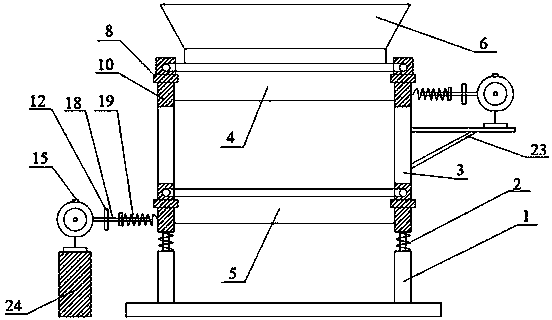

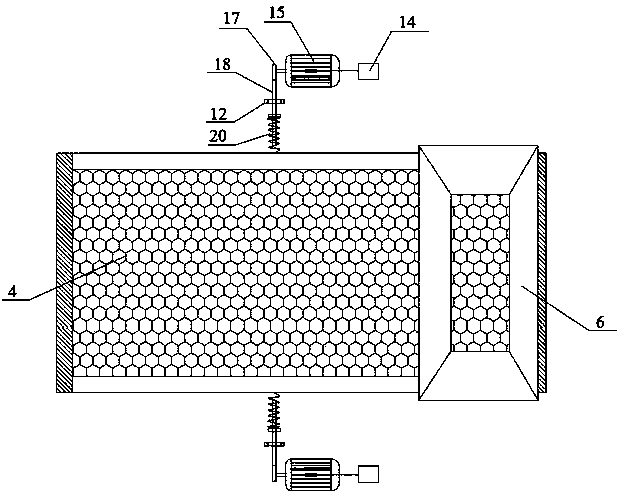

[0022] An example of an energy-saving vibrating screen of the present invention is Figure 1~Figure 7 As shown, it includes a vibrating screen base 1, a frame 3 supported on the vibrating screen base 1 by a damping spring 2, and an upper screen body 4 and a lower screen body 5 arranged at intervals up and down on the frame 3, the vibrating screen base 1, The damping spring 2 and the frame 3 constitute a support device for supporting the screen body.

[0023] Both the upper sieve body 4 and the lower sieve body 5 are rectangular, arranged obliquely relative to the horizontal plane, and ball bearings 7 are respectively provided at the respective four corners. The ball support 7 includes a sieve body support 8 , a support seat 10 and a ball 9 rollingly supported between the sieve body support 8 and the support seat 10 . The sieve body support 8 is a groove structure with the opening downward and the upper part is provided with a hinged seat, and the sieve body can be connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com