Phase change energy storage greenhouse and working method

A phase-change energy storage and greenhouse technology, which is applied in the field of agricultural greenhouses, can solve the problems of unsatisfactory heat exchange efficiency and structural optimization design of energy storage modules, multi-equipment control, and high energy consumption, so as to reduce structural strength requirements and improve heat exchange efficiency High, saving installation and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

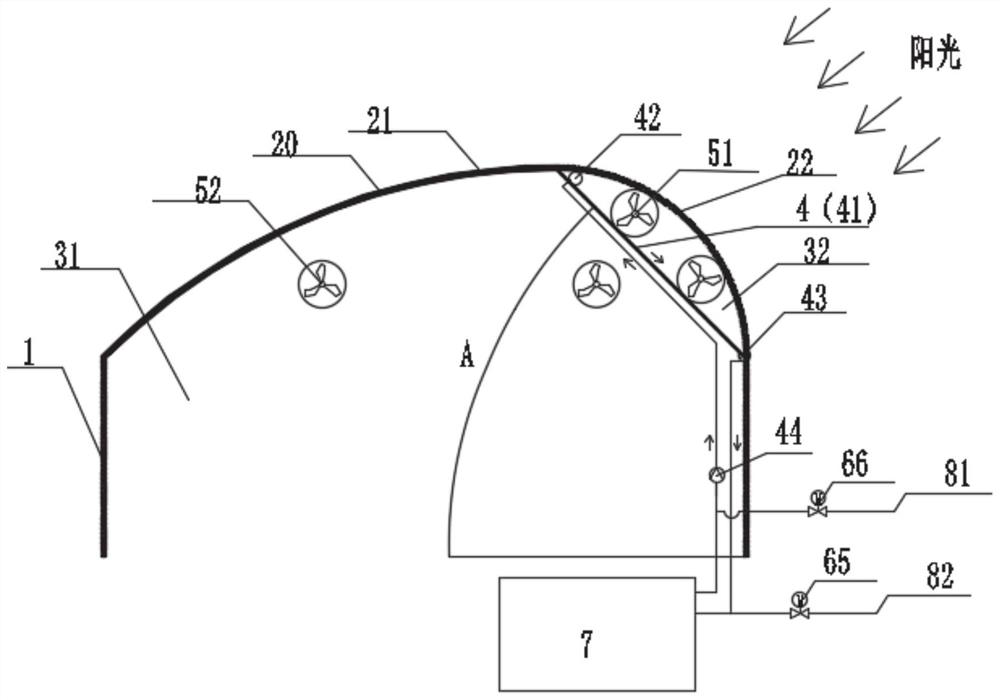

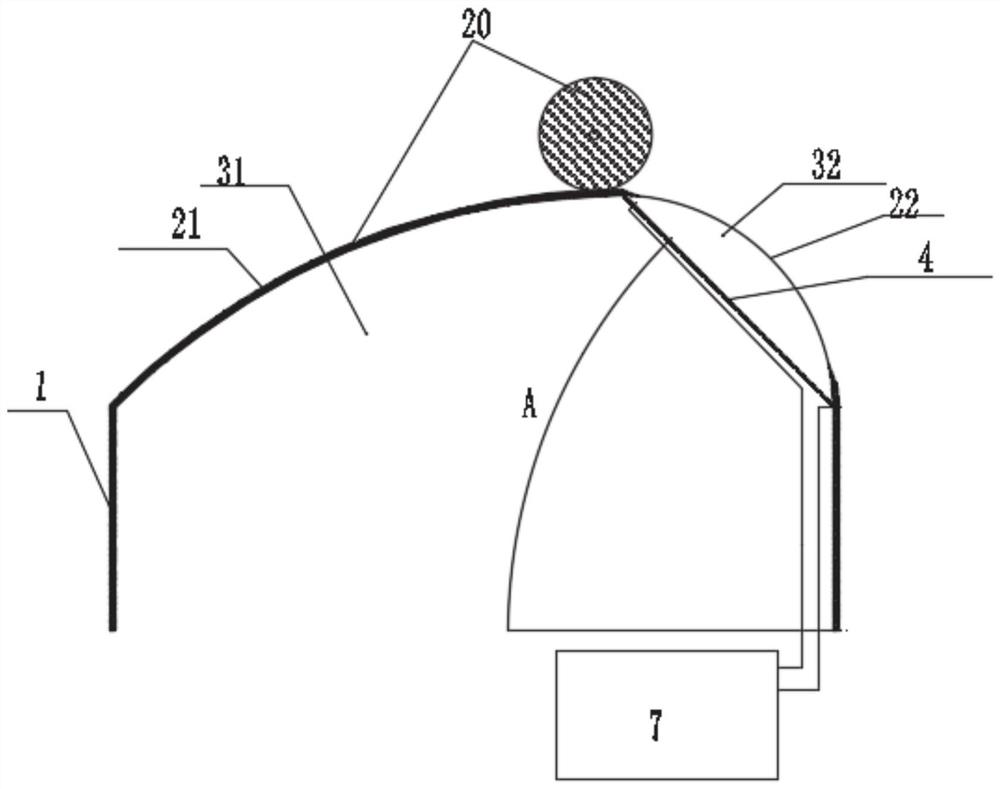

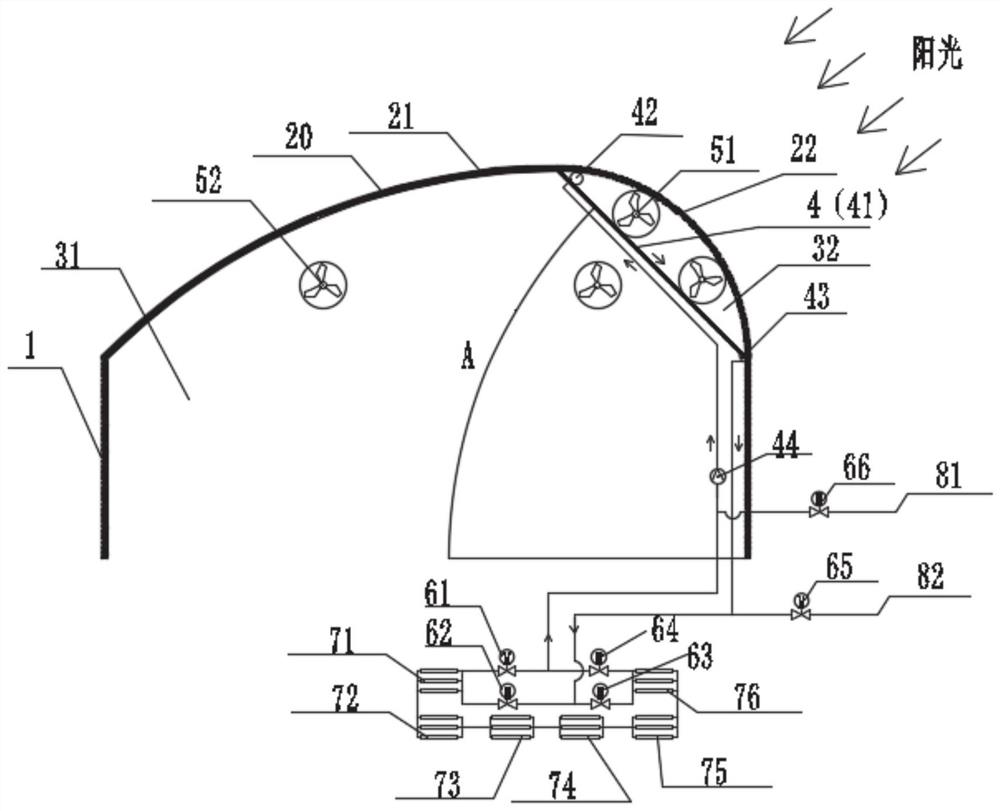

[0042] Such as Figure 1-3As shown, a phase-change energy storage greenhouse includes a frame and a vault at the top of the frame. The vault includes a south vault 22 on the side close to the sunlight and a north vault 21 on the side away from the sunlight. The vault reaches Diagonal braces 4 are set between the gables on the south side to physically divide the greenhouse into production chamber 31 and temperature regulation chamber 32. Set the angle range, specifically: not lower than the latitude value of the greenhouse location and not higher than 23.5 degrees of the greenhouse location latitude value; the side surface of the diagonal brace 4 facing the temperature adjustment cavity 32 is connected to the heat exchange component 41, and the heat exchange component 41 passes through The pipeline connects the phase change energy storage components located underground in the greenhouse;

[0043] The working medium in the heat exchange component 41 transfers the heat in the su...

Embodiment 2

[0056] The working method of the phase change energy storage greenhouse with the above structure is as follows:

[0057] Setting: the phase change temperature of the first phase change energy storage module 71 is 10°C, the phase change temperature of the second to fourth phase change energy storage modules 72, 73, 74 is 20°C, and the phase change temperature of the fifth phase change energy storage module 75 The phase change temperature is 25°C, and the phase change temperature of the sixth phase change energy storage module 76 is 30°C;

[0058] The cultivated crop species is Pleurotus ostreatus, the mycelial growth temperature range is 5-32°C, the optimum temperature is 20-22°C, the fruiting body growth temperature is 2-30°C, and the optimum temperature is 16-20°C.

[0059] Heat storage:

[0060] At about 9:00 in the morning on a sunny day, roll up the insulation quilt on the south vault, and the heat exchange partition (membrane) is irradiated by the sun, and the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com