Metal plastic extrusion forging method

A forming method and plastic technology, applied in the field of metal extrusion forging, can solve the problems of large extrusion forging force, high extrusion forging difficulty, workpiece blank deformation, etc., meet the requirements and low requirements of the power system, improve internal structure performance, performance The effect of reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A metal plastic extrusion forging method, comprising the following steps:

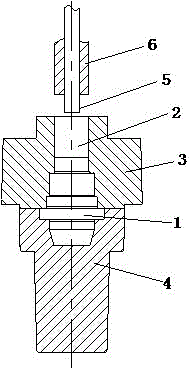

[0029] (1) Prepare extrusion forging equipment (such as figure 1 shown), the extrusion forging equipment has an openable and closed cavity 1 and a first extrusion channel 2 communicating with the cavity 1; the openable and closed cavity 1 is formed by the upper The mold 3 and the lower mold 4 are formed, and the first extrusion forging channel 2 is arranged on the upper mold 3;

[0030] (2) Steps of feeding and extrusion, to open the cavity 1, put the workpiece blank into the cavity 1 or the first extrusion forging channel 2, and close the cavity 1 after closing the mold, and adopt the extrusion end face size smaller than the first extrusion forging The first punching part 5 of the cross-sectional size of the channel 2 is inserted into the first extrusion forging channel 2 to squeeze holes on the workpiece blank, and the workpiece blank produces a plastic deformation;

[0031] (3) In the formi...

Embodiment 2

[0039] A metal plastic extrusion forging method, comprising the following steps:

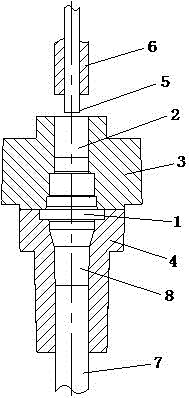

[0040] (1) Prepare extrusion forging equipment (such as figure 2 shown), the extrusion forging equipment has an openable and closed cavity 1 and a first extrusion channel 2 communicating with the cavity 1; the openable and closed cavity 1 is formed by the upper The mold 3 and the lower mold 4 are formed, and the first extrusion forging channel 2 is arranged on the upper mold 3 . The extruding and forging molding equipment also has a second extruding hole member 7 and a second extruding forging channel 8 communicated with the cavity 1, the second extruding forging channel 8 is arranged in the lower die 4, and the cross-sectional size of the second extruding hole member 7 is the same as that of the first forging channel. The cross-sectional dimensions of the two extrusion forging channels 8 are consistent, and the second extrusion forging channel 8 is coaxial and opposite to the first extrusion ...

Embodiment 3

[0049] A metal plastic extrusion forging method, comprising the following steps:

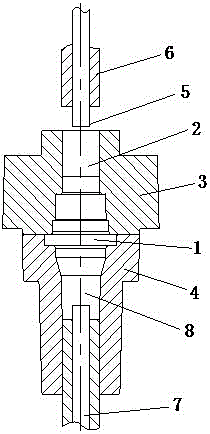

[0050] (1) Prepare extrusion forging equipment (such as image 3 shown), the extrusion forging equipment has an openable and closed cavity 1 and a first extrusion channel 2 communicating with the cavity 1; the openable and closed cavity 1 is formed by the upper The mold 3 and the lower mold 4 are formed, and the first extrusion forging channel 2 is arranged on the upper mold 3 . The extruding and forging molding equipment also has a second extruding hole member 7 and a second extruding forging channel 8 communicated with the cavity 1, the second extruding forging channel 8 is arranged in the lower die 4, and the cross-sectional size of the second extruding hole member 7 is the same as that of the first forging channel. The cross-sectional dimensions of the two extrusion forging channels 8 are consistent, and the second extrusion forging channel 8 is coaxial and opposite to the first extrusion f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com