A dual-head 3D printer that can rotate and switch print heads

A 3D printer and print head technology, applied in the field of 3D printers, can solve problems such as damage to the surface, printing can not continue, affect the surface quality of the workpiece, etc., to achieve the effect of solving poor printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

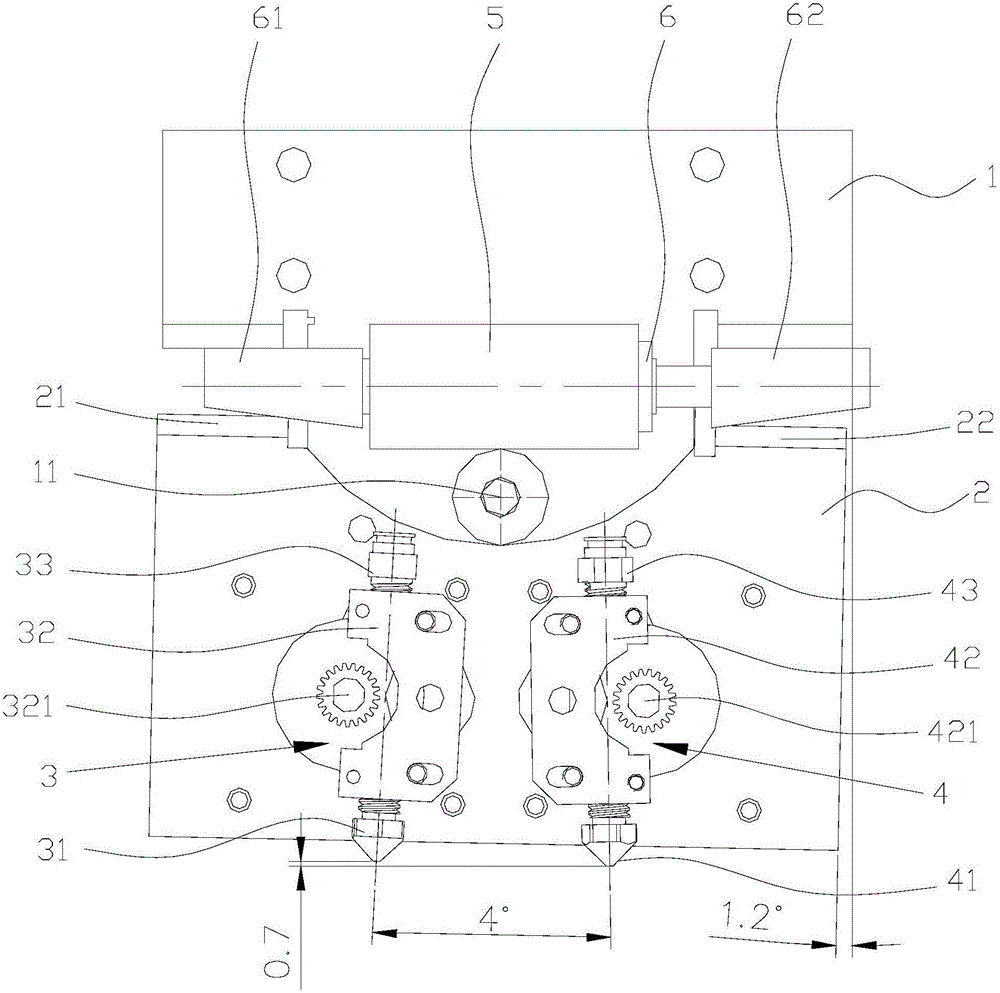

[0026] see figure 1 , a dual-head 3D printer that can rotate and switch print heads, it includes a fixed plate 1, a mounting plate 2 rotatably connected to the fixed plate 1, a first print head 3 and a second print head mounted on the mounting plate 2 in parallel print head 4.

[0027] A fixed rotating shaft 11 is arranged on the fixed plate 1 , and the axial direction of the fixed rotating shaft 11 in this embodiment is arranged along the horizontal direction. The mounting plate 2 is rotatably connected to the fixed rotating shaft 11 with the axis of the fixed rotating shaft 11 as the center line of rotation. The first printing head 3 is located on the lower left side of the fixed rotating shaft 11 , and the second printing head 4 is located on the lower right side of the fixed rotating shaft 11 . The first print head 3 and the second print head 4 are arranged left and right symmetrically with the vertical line where the axis of the fixed rotating shaft 11 is located as the...

Embodiment 2

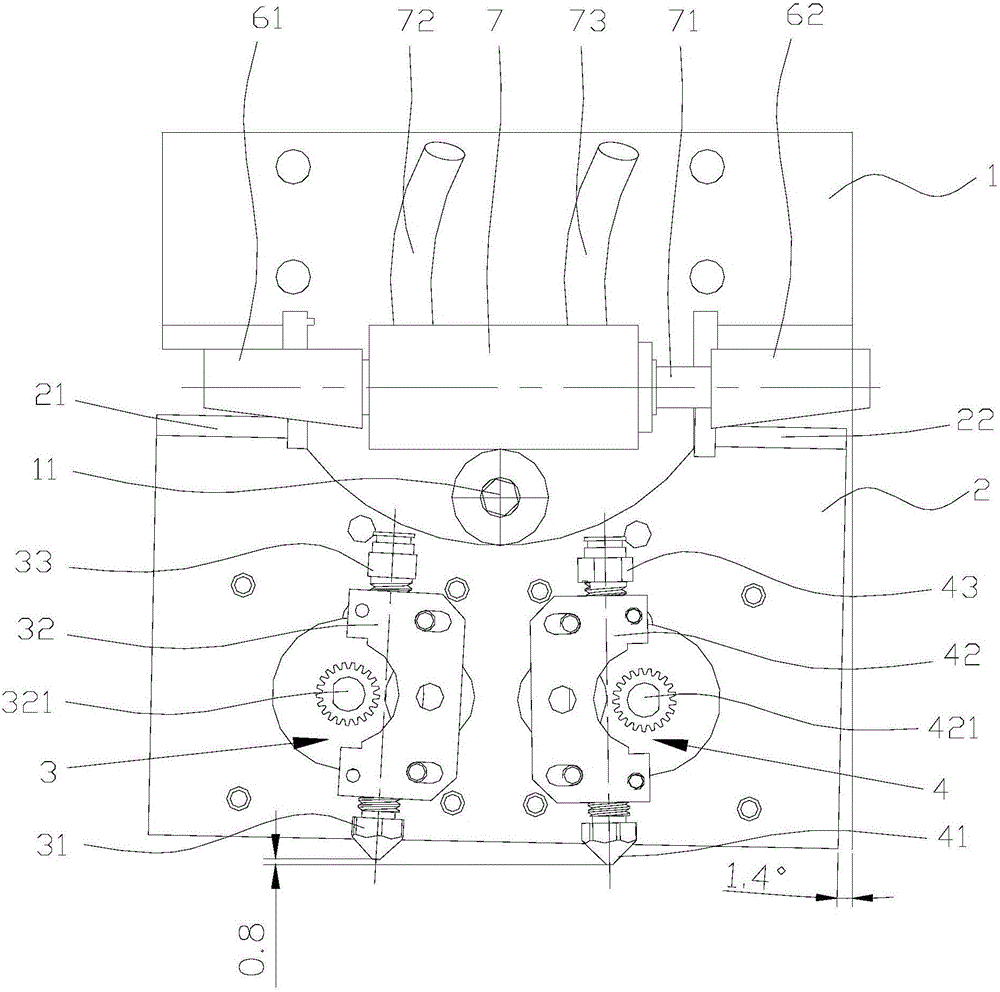

[0046] like figure 2 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the electromagnetic coil 5 is replaced by a double-acting cylinder 7, and the double-acting cylinder 7 is arranged horizontally, and a piston rod that can move left and right along its own axis is arranged inside it. 71. Left wedge block 61 is installed on the left end of piston rod 71, and right wedge block is installed on the right end of piston rod 71. The left and right sides of the double-acting cylinder 7 are respectively provided with a first air pipe 72 and a second air pipe 73, and the air source of the external air supply device supplies air to the first air pipe 72 and the second air pipe 73 respectively. Down, push the piston rod 71 to move left and right, so as to drive the mounting plate 2 to rotate counterclockwise or clockwise, so as to achieve the technical effect of swinging left and right to switch the print head for printing. ...

Embodiment 3

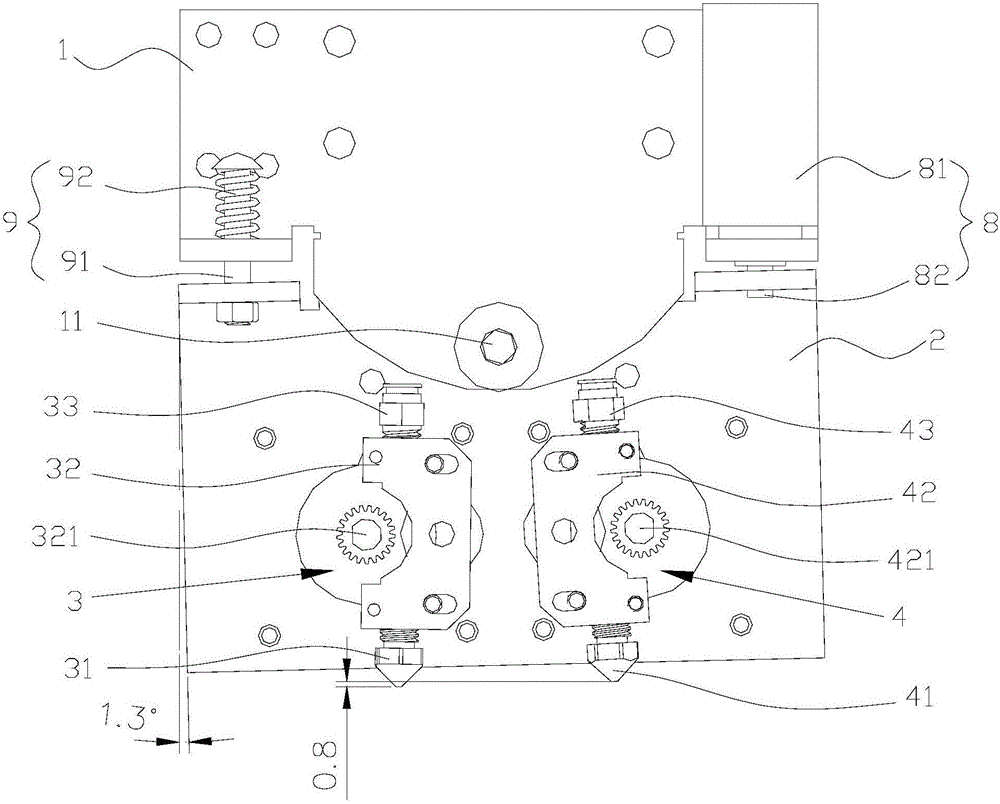

[0050] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that the driving mechanism includes a reversing electromagnetic device 8 installed on the right side of the fixed plate 1, and the reversing electromagnetic device 8 includes a reversing electromagnetic coil 81 and is arranged on a reversing electromagnetic coil that can move up and down. To the electromagnet core 82 in the electromagnetic coil 81 , the right upper end of the electromagnet core 82 is connected to the mounting plate 2 . The driving mechanism also includes an elastic reset device 9 installed on the left side of the mounting plate 2. The elastic reset device 9 includes a stop rod 91 with one end fixed on the install plate 2. The upper end of the stop rod 91 and the fixed plate 1 A spring 92 is provided in the sleeve.

[0051] When the print head is switched to print, the reversing electromagnetic coil 81 is powered on, and the electromagnetic core 82 moves upward, driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com