Large-sized green brick storing method and device used in front of kiln

A billet storage and large-scale technology, applied in the field of billet storage methods and devices, can solve the problems of limited ability to store adobe, complicated civil engineering, and the inability of adobe to leave the billet storage machine first, achieving time balance, simple civil engineering and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

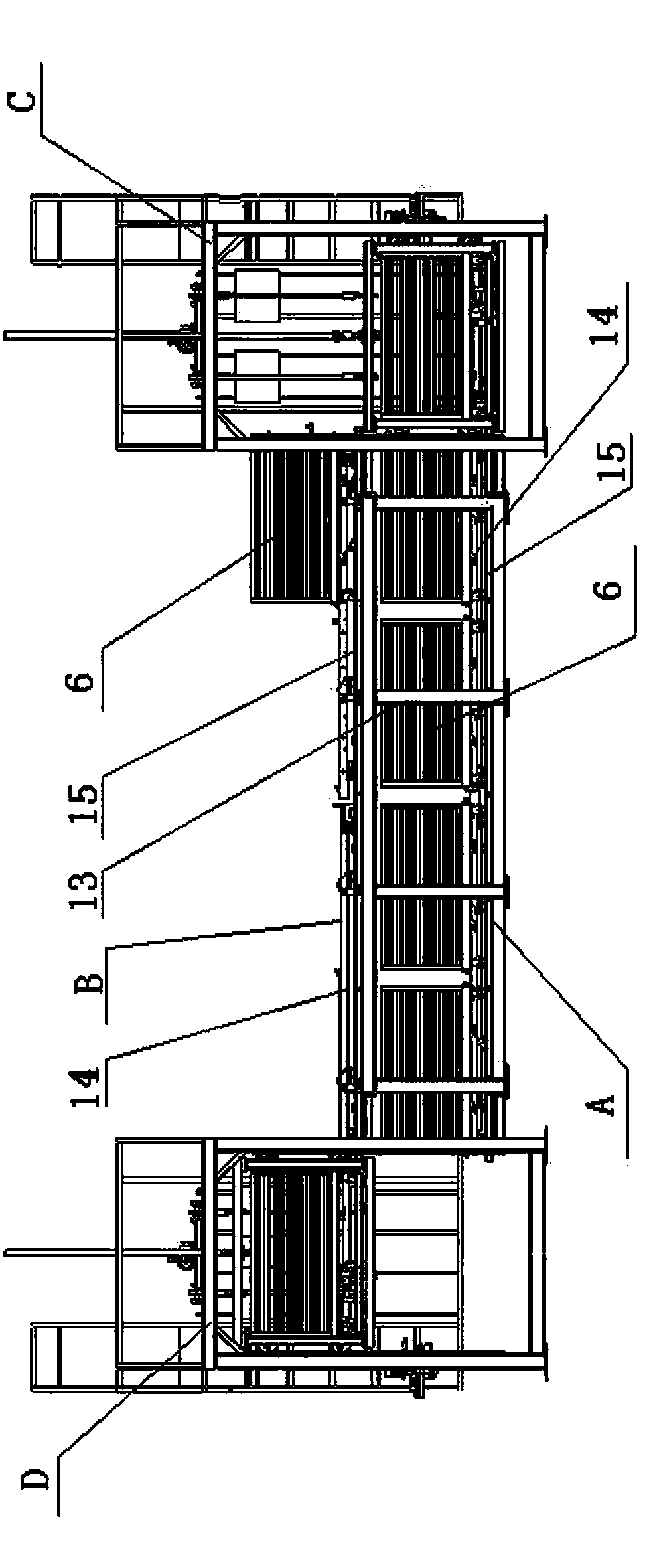

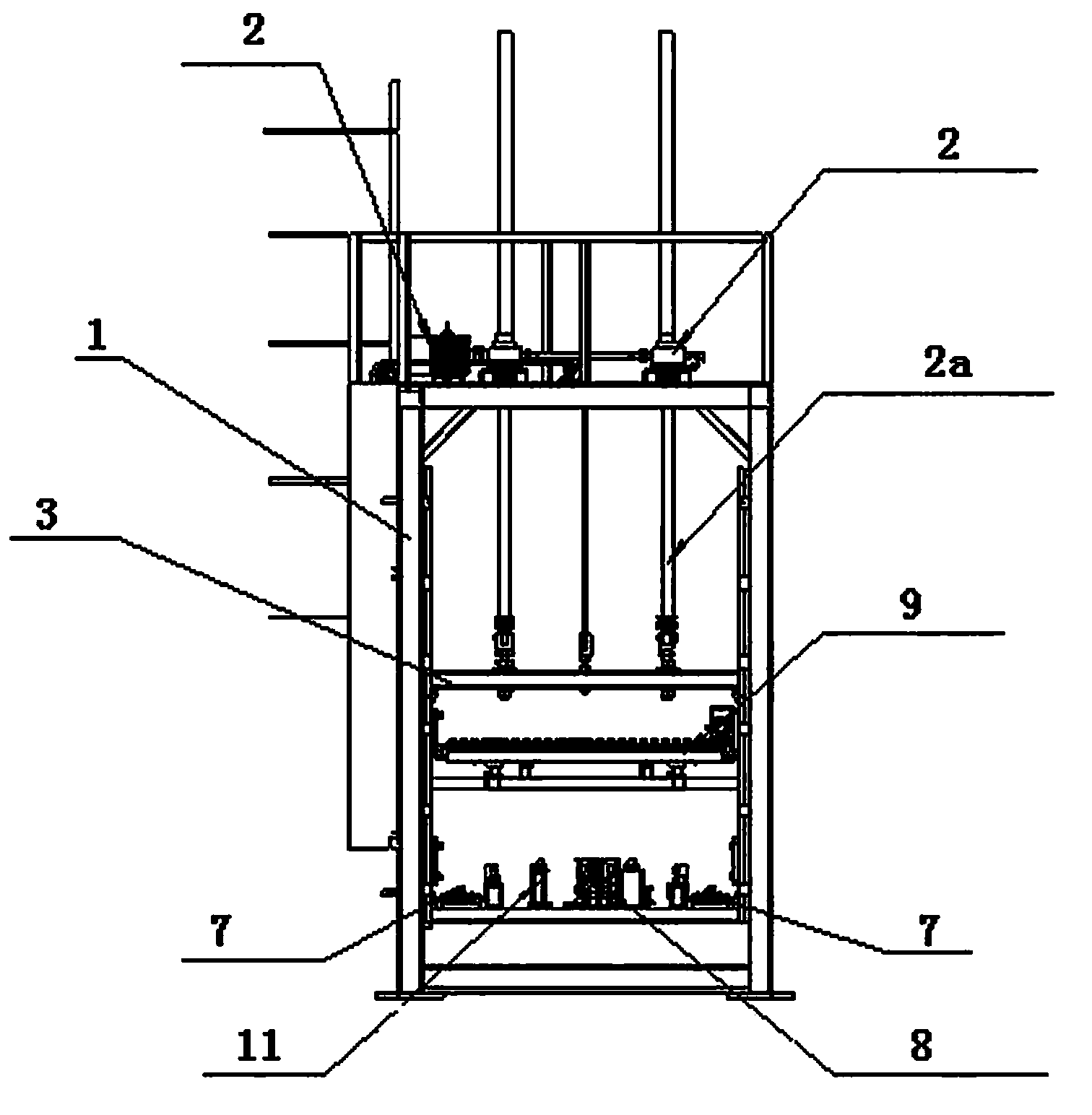

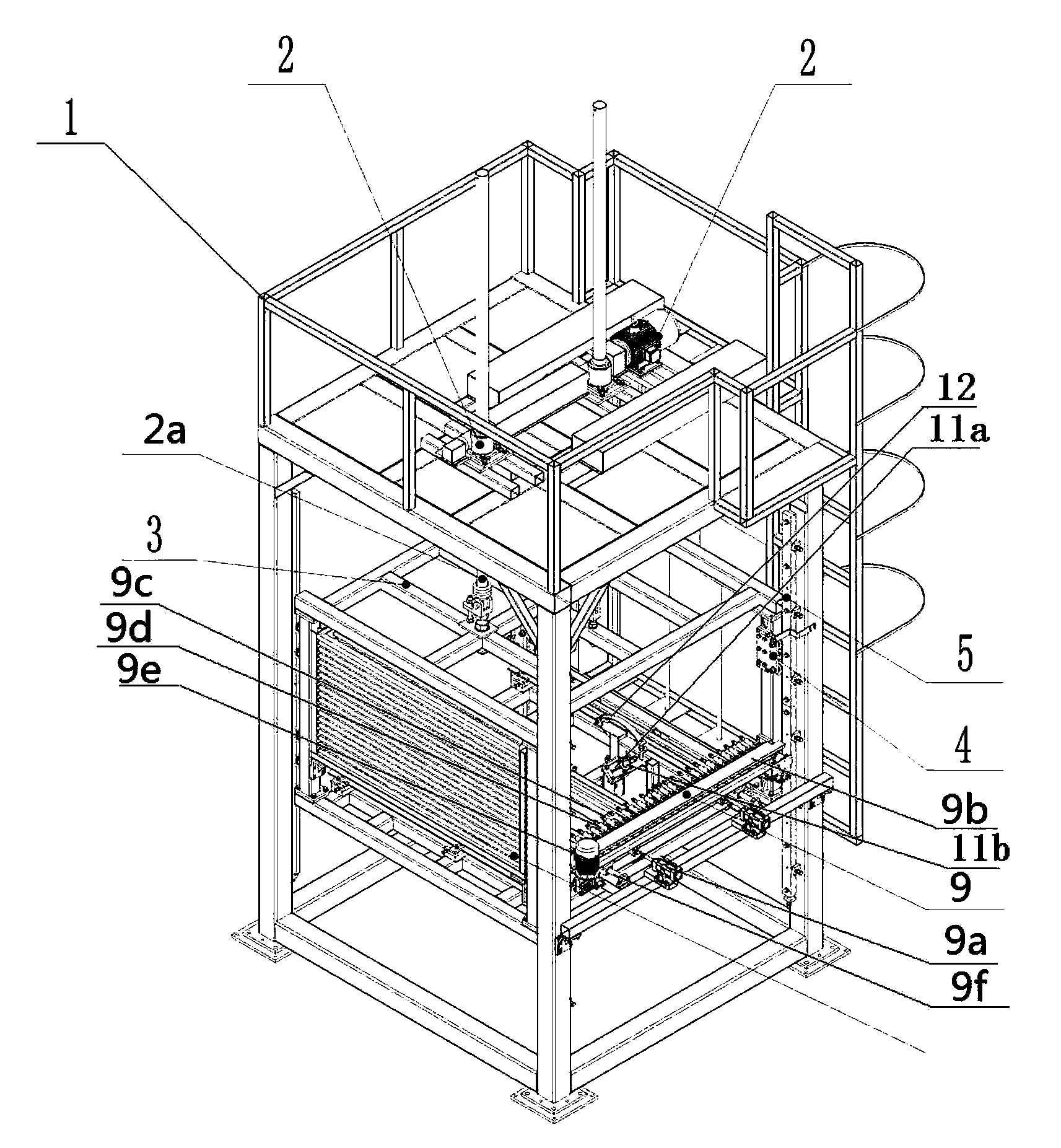

[0021] As shown in the figure, the large billet storage device in front of the kiln of the present invention is realized in this way, including a lower transmission mechanism A, an upper transmission mechanism B located above the lower transmission mechanism A, a lifting mechanism C located at one end of the lower transmission mechanism A, a The brick lifting mechanism D at the other end of the lower transmission mechanism A, the blank storage car 6, and the vehicle frame 6a with wheels of the blank storage vehicle 6d are provided with a multi-layer storage layer consisting of several transmission rollers 6c that rotate in parallel. 6b, the lifting mechanism C is provided with a storage car power transmission mechanism 8, and the brick output lifting mechanism D is provided with a storage car power transmission mechanism 8 and a brick transmission device 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com