A chlorine dioxide gas preparation system and preparation method thereof

A chlorine dioxide and chlorine dioxide technology, applied in chlorine oxide and other directions, can solve problems such as affecting safe production, high preparation cost, equipment damage, etc., and achieve the effects of enhanced safety, easy operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

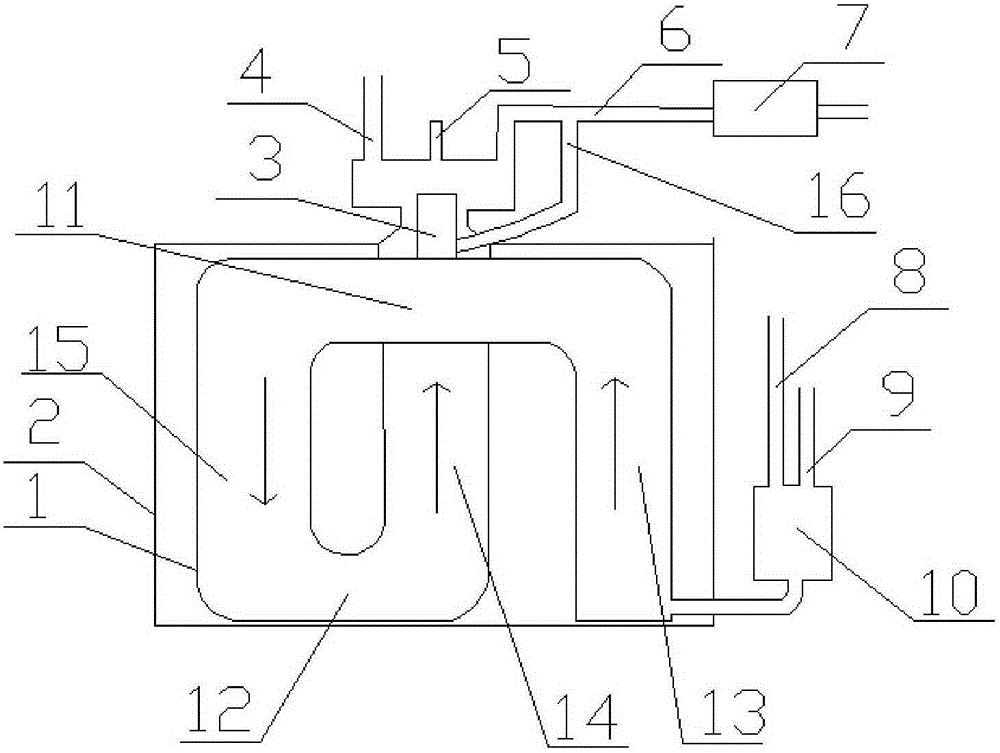

[0030] Such as figure 1 As shown, a chlorine dioxide gas preparation system includes a control cabinet, a mixer 10, a gas generator 1 and an aspirator 7; the gas generator 1 is a rotary type, and the inlet of the gas generator 1 is connected to the outlet of the mixer 10 Connection, the outlet end of the gas generator is connected to the inlet of the air extractor 7 through the outlet pipe 6; the outlet end of the gas generator is provided with a water inlet pipe 4 and a pressure sensor 5; the pressure sensor is connected to the control cabinet.

[0031] The above scheme can already complete the preparation of high-purity chlorine dioxide gas, and on this basis, the preferred scheme is given:

[0032] The gas generator 1 comprises a first horizontal pipeline 11, a second horizontal pipeline 12, a first vertical pipeline 13, a second vertical pipeline 14 and a third vertical pipeline 15; the top of the first vertical pipeline 13 and the third vertical pipeline The top of the p...

Embodiment 2

[0034] A method for preparing high-purity chlorine dioxide gas using the chlorine dioxide gas preparation system of embodiment 1, comprising the steps of:

[0035] A. Pretreat the feed liquid and the gas generator: first fill the gas generator 1 with clean water through the water inlet pipe 4, and then mix the sodium chlorite solution with a mass fraction of 8% and the sodium chlorite solution with a mass fraction of 8-9% The hydrochloric acid solution is injected into the static mixer 10 through the sodium chlorite solution delivery pipe 8 and the hydrochloric acid solution delivery pipe 9 according to the molar ratio of 1:2.4 to 1:2.75, and pre-mixed in the static mixer 10;

[0036] B. After the feed liquid is pre-mixed in the static mixer 10, it is injected into the gas generator 1 from the inlet end of the gas generator 1, where it reacts to generate chlorine dioxide gas, and the reaction temperature of the feed liquid in the gas generator 1 is At normal temperature, the r...

Embodiment 3

[0040] A method for preparing high-purity chlorine dioxide gas using the chlorine dioxide gas preparation system of embodiment 1, comprising the steps of:

[0041] A. Pretreat the feed liquid and the gas generator: first fill the gas generator 1 with clean water through the water inlet pipe 4, and then fill the gas generator 1 with 8% sodium chlorite solution and 8% hydrochloric acid solution Inject the static mixer 10 through the sodium chlorite solution delivery pipe 8 and the hydrochloric acid solution delivery pipe 9 according to the molar ratio of 1:2.42, and pre-mix in the static mixer 10;

[0042] B. After the feed liquid is mixed in the static mixer 10, it is injected into the gas generator 1 from the inlet end of the gas generator 1, where it reacts to generate chlorine dioxide gas, and the reaction temperature of the feed liquid in the gas generator 1 is normal temperature , the reaction time is 0.4h; Then chlorine dioxide gas and the reacted feed liquid are extracte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com