Formula for firing light ceramic once and production method of light ceramic

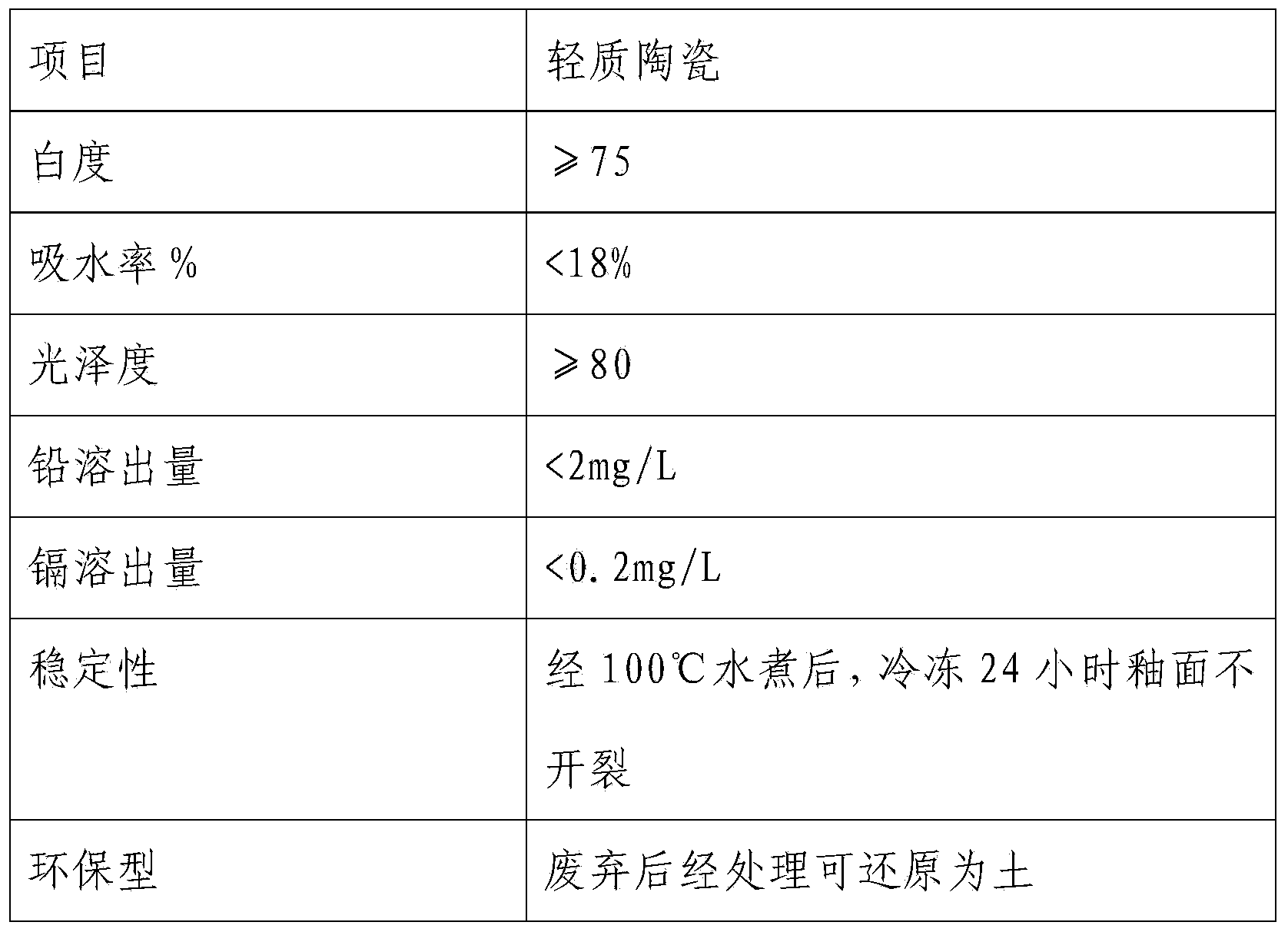

A technology of lightweight ceramics and manufacturing methods, applied in the field of ceramic manufacturing, can solve the problems that the products are difficult to reach high-end products, the product has a high water absorption rate, and affects the quality of the product, so as to achieve the effect of reducing energy consumption, reducing the water absorption rate, and alleviating energy shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] Specific embodiment one: according to parts by weight, the blank formula of the lightweight ceramics is as follows: 25 parts of kaolin, 8 parts of low-temperature sand, 15 parts of pyrophyllite, 20 parts of clay, 22 parts of wollastonite, 5 parts of feldspar, magnesia 5.

specific Embodiment 2

[0027] Specific embodiment two: according to parts by weight, the blank formula of the lightweight ceramics is as follows: 28 parts of kaolin, 5 parts of low-temperature sand, 8 parts of pyrophyllite, 22 parts of clay, 20 parts of wollastonite, 7 parts of feldspar, magnesia 10;

[0028] According to mass percent, the chemical composition of the blank formula of the lightweight ceramics of specific embodiments one to four is as follows: SiO 2 58.87%, Al 2 o 3 17.04%, Fe 2 o 3 0.24%, CaO 10.70%, MgO 4.52%, K 2 O 2.35%, Na 2 O 0.85%, IL 5.33%.

specific Embodiment 3

[0029] Specific embodiment three: according to parts by weight, the blank formula of the lightweight ceramics is as follows: 21 parts of kaolin, 6 parts of low-temperature sand, 20 parts of pyrophyllite, 20 parts of clay, 14 parts of wollastonite, 4 parts of feldspar, magnesia 15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com