Paint remover and paint removing method thereof

A paint remover and thickener technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of inapplicability to PCB boards, inability to remove paint removal time, unsuitable for partial paint removal, etc., to improve Penetration, improvement of paint removal efficiency, effect of high paint removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations of the present invention are now described.

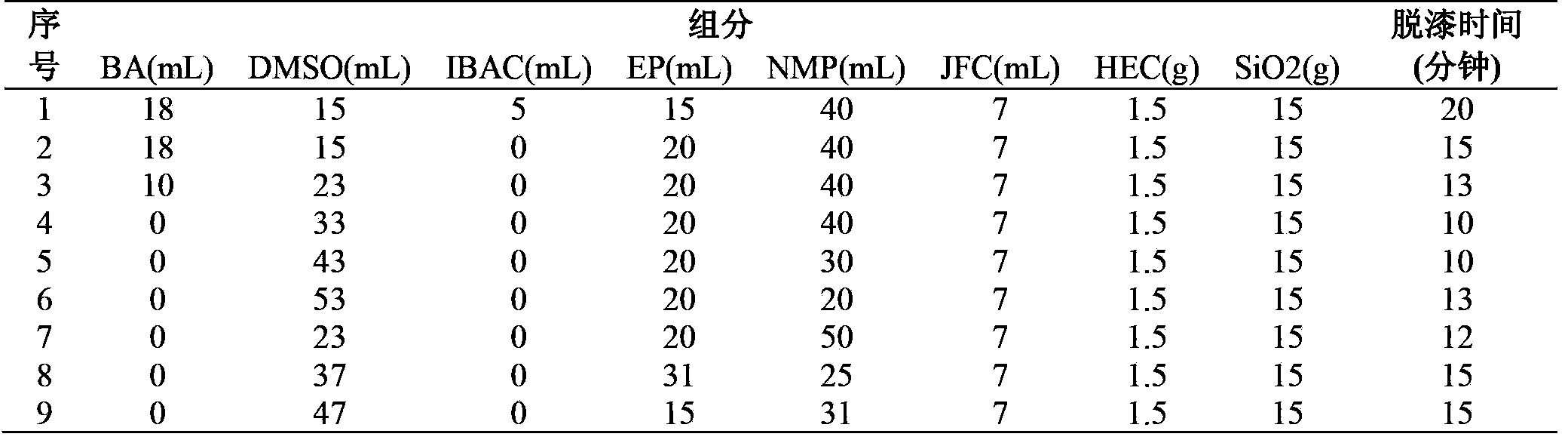

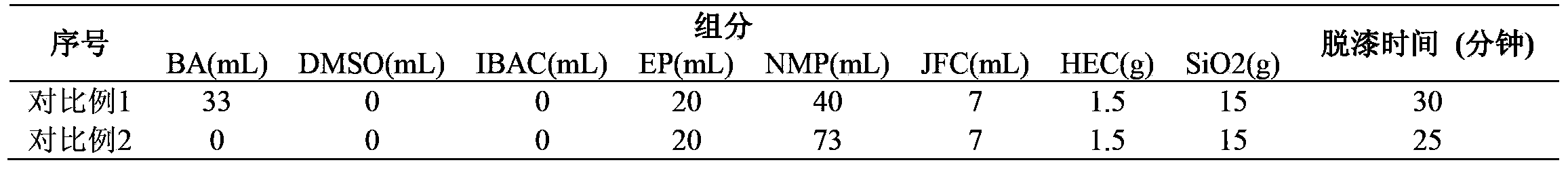

[0026] This embodiment provides a paint remover for partially removing the conformal paint on the PCB. The material of the conformal paint is polyurethane-modified alkyd resin, and the thickness of the paint film is about 60 microns. The specific contents of the various components of the paint remover provided in this embodiment are shown in Table 1. When the paint remover is partially coated on the part of the three anti-paint that needs to be removed, the three anti-paint material will swell after a period of time, so that it can be easily peeled off from the surface of the PCB board. Table 1 shows 10 paint remover formulations with different component ratios and the paint stripping time corresponding to each formulation (even the time required for the three anti-paint to swell e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com