A method for preparing porous nanofibrous materials by high-voltage electrospinning

A high-voltage electrospinning and nanofiber technology, which is applied in electrospinning, fiber treatment, chemical instruments and methods, etc., can solve the problems of high cost of organic sewage treatment, poor reuse times, and limited application of porous nanofiber materials. , to achieve excellent adsorption effect, uniform shape, and enhance the effect of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

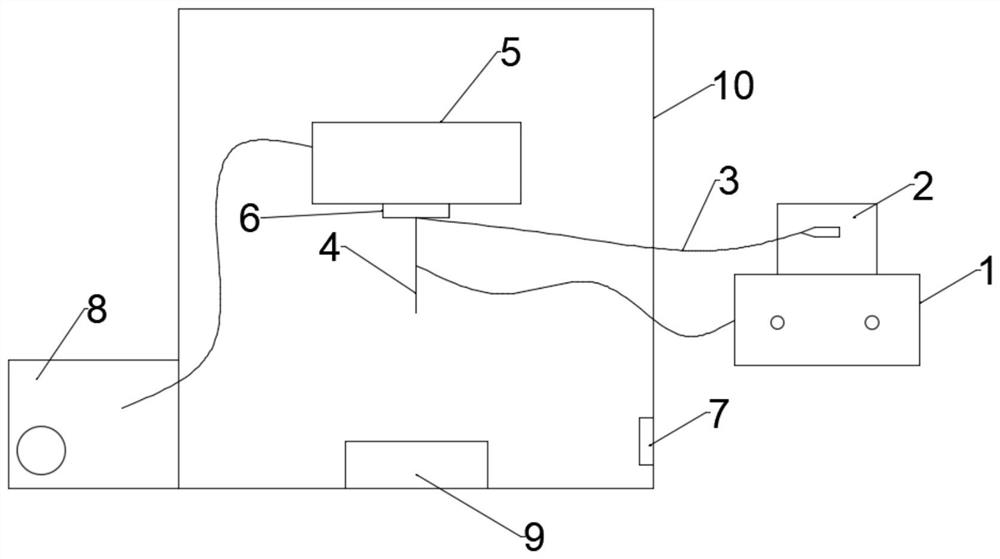

Image

Examples

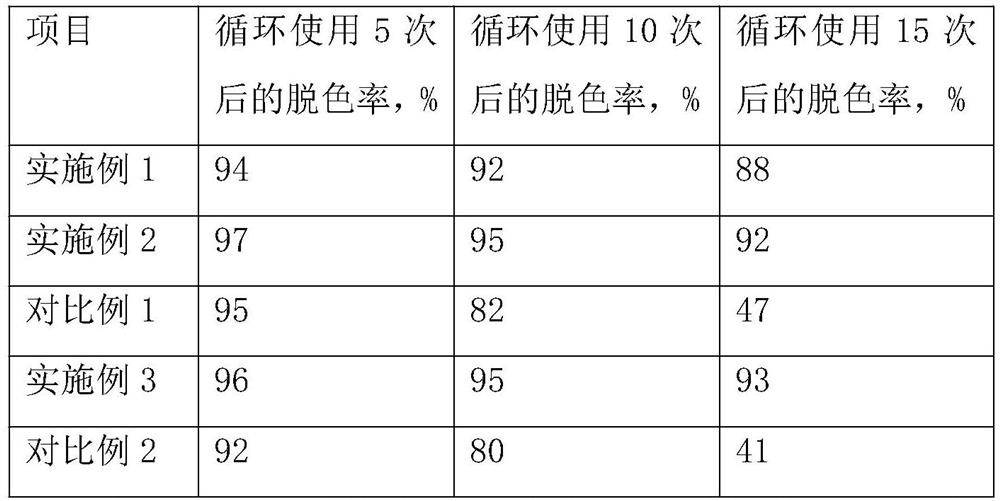

Embodiment 1

[0024] A method for preparing a porous nanofibrous material by high-voltage electrospinning, comprising the following steps:

[0025] (1) Poly-L-lactic acid is dissolved in a solvent system with chloroform as the main solvent and methanol and isopropanol as co-solvents to obtain a spinning solution, wherein the volume ratio of chloroform, methanol and isopropanol 10:1:1, the mass fraction of poly-L-lactic acid dissolved in the spinning solution is 10%;

[0026] (2) After dissolving praseodymium oxide and zirconia with nitric acid solution, the rare earth nitric acid solution is prepared, which is added to the spinning solution, and after mixing and stirring evenly, ammonia water is continuously added to it, stirring while adding, until the pH value is After 2.6, obtain the spinning solution, finally add its mass 1% magnesium stearate in the spinning solution, wherein the mass fraction of nitric acid solution is 10%, and the mass ratio of praseodymium oxide, zirconium oxide and...

Embodiment 2

[0031] A method for preparing a porous nanofibrous material by high-voltage electrospinning, comprising the following steps:

[0032] (1) Poly-L-lactic acid is dissolved in a solvent system with chloroform as the main solvent and methanol and isopropanol as co-solvents to obtain a spinning solution, wherein the volume ratio of chloroform, methanol and isopropanol 10:1:1, the mass fraction of poly-L-lactic acid dissolved in the spinning solution is 13%;

[0033] (2) After dissolving praseodymium oxide and zirconia with nitric acid solution, the rare earth nitric acid solution is prepared, which is added to the spinning solution, and after mixing and stirring evenly, ammonia water is continuously added to it, stirring while adding, until the pH value is After 2.8, the spinning solution is obtained, wherein the mass fraction of nitric acid solution is 10-15%, the mass ratio of praseodymium oxide, zirconium oxide and nitric acid solution is 1:5:30, and the mass ratio of rare earth...

Embodiment 3

[0037] A method for preparing a porous nanofibrous material by high-voltage electrospinning, comprising the following steps:

[0038] (1) Poly-L-lactic acid is dissolved in a solvent system with chloroform as the main solvent and methanol and isopropanol as co-solvents to obtain a spinning solution, wherein the volume ratio of chloroform, methanol and isopropanol 10:1:1, the mass fraction of poly-L-lactic acid dissolved in the spinning solution is 15%;

[0039] (2) After dissolving praseodymium oxide and zirconia with nitric acid solution, the rare earth nitric acid solution is prepared, which is added to the spinning solution, and after mixing and stirring evenly, ammonia water is continuously added to it, stirring while adding, until the pH value is After 3.0, the spinning solution is obtained, wherein the mass fraction of nitric acid solution is 15%, the mass ratio of praseodymium oxide, zirconium oxide and nitric acid solution is 1:6:30, and the mass ratio of rare earth ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com