Process of making a hollow member having an internal coating and turbine components

A technology of inner coating and hollow casting, which is applied in the field of manufacturing a hollow casting component, and can solve the problem that the spraying process cannot be satisfactorily applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

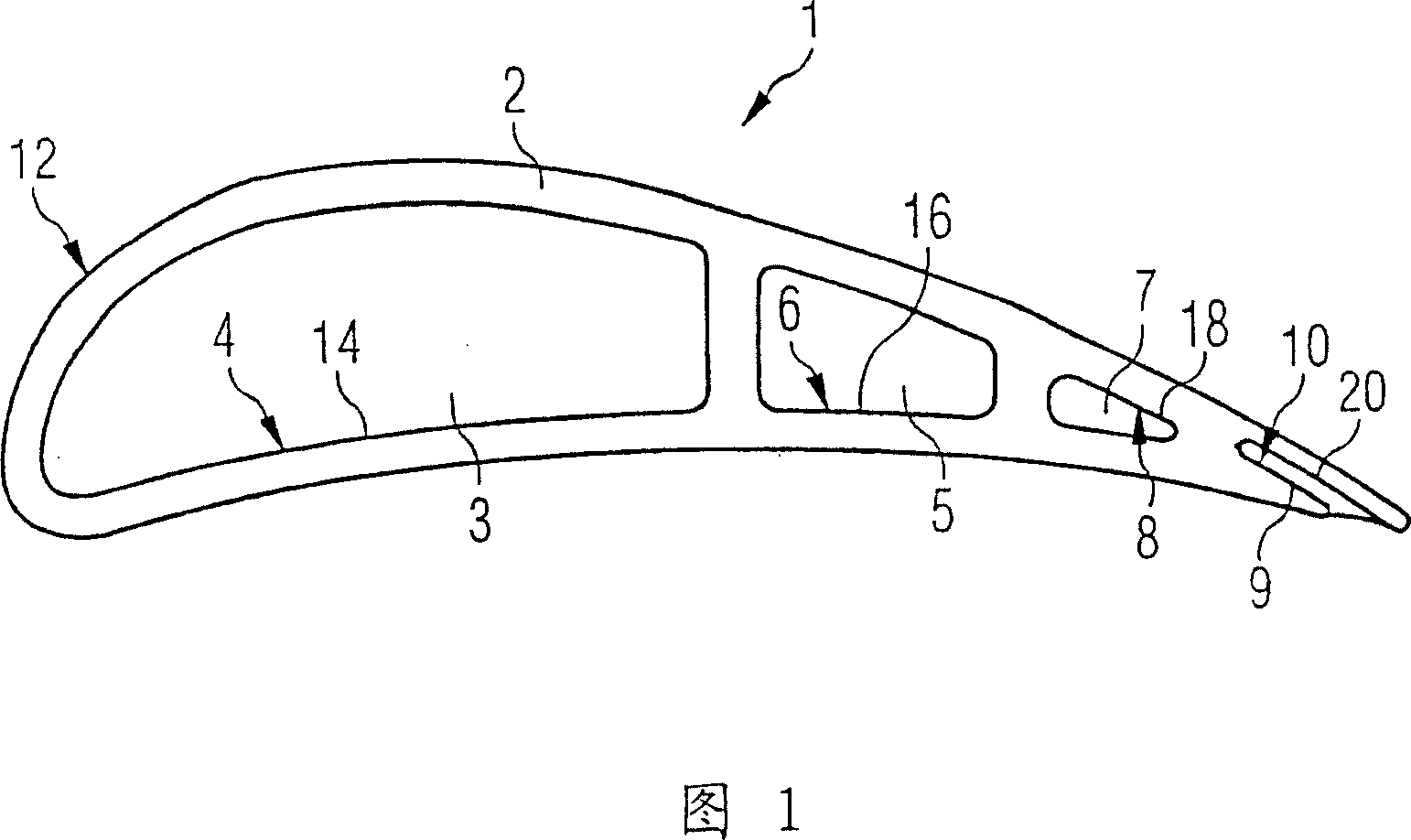

[0020] FIG. 1 is a schematic sectional view of a hollow cast turbine blade 1 . The turbine blade 1 includes a blade body 2 . In the exemplary embodiment shown, four cavities 3 , 5 , 7 , 9 are formed in the blade body 2 . These cavities are used, for example, for cooling air to flow through. The blade body 2 has an outer surface 12 . The outer surface is protected against oxidation and / or corrosion with a MCrAlY coating. In addition, the blade body 2 also has inner surfaces 4 , 6 , 8 , 10 . These inner surfaces define cavities 3, 5, 7, 9 and form the inner walls of these cavities. These inner surfaces 4, 6, 8, 10 are likewise provided with an MCrAlY coating 14, 16, 18, 20 to protect against corrosion and / or oxidation.

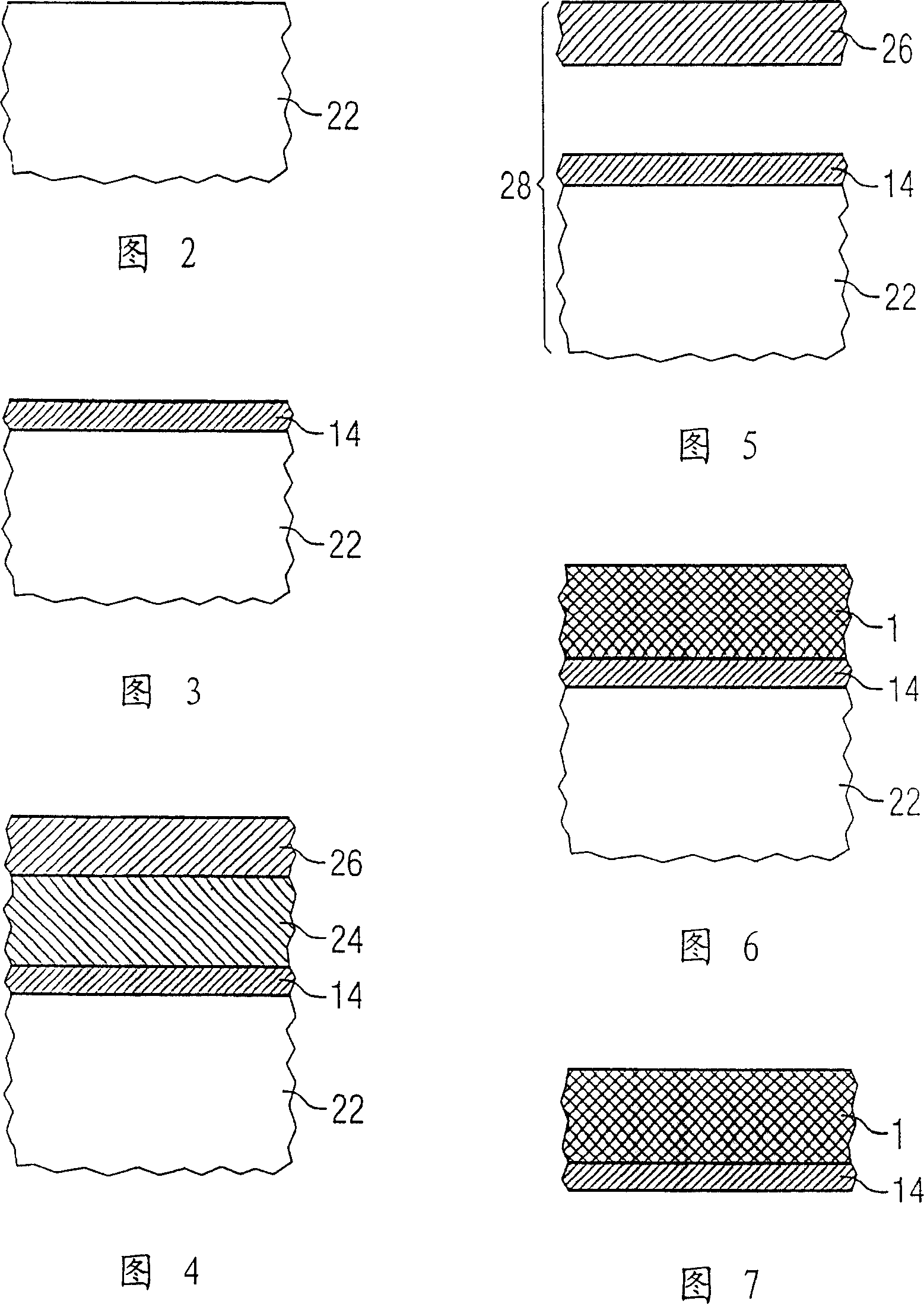

[0021] The method for producing the turbine blade 1 shown in FIG. 1 is described below with reference to FIGS. 2 to 7 . However, the method can also be used for internal coating of other hollow cast components.

[0022] As a first step, a ceramic casting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com