Low-density high-strength petroleum ceramsite proppant taking tuff as main raw material, and preparation method thereof

A main raw material, tuff technology, applied in ceramic products, chemical instruments and methods, earthwork drilling and mining, etc., to achieve the effects of increasing oil development rate, increasing the strength of ceramsite, and reducing firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

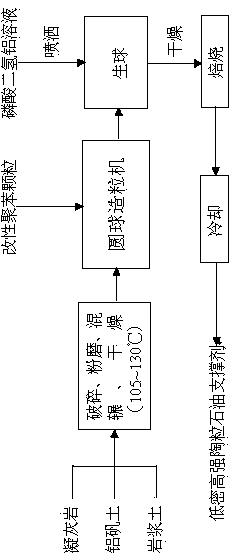

Method used

Image

Examples

preparation example Construction

[0022] Described a kind of low-density high-strength petroleum ceramsite proppant with tuff as main raw material, its preparation method comprises the following steps:

[0023] 1) Weigh the tuff mineral powder, bauxite particles and magmatic soil particles according to the weight ratio, and dry them under the temperature condition of 105-130°C for 2-4 hours, and then mix them evenly to prepare the mixture;

[0024] 2) Add the mixture and modified polyphenylene particles prepared in step 1) into the ball granulator to form green balls. During the granulation process, spray industrial diphosphate diphosphate with a weight concentration of 0.5-1.0% on the surface of the green balls. Aluminum hydrogen phosphate solution until the surface of the sphere is wetted, and then dried at 130-160°C for 2-4 hours to obtain a dry ball. close;

[0025] 3) Calcining the dry balls prepared in step 2) at a temperature of 1080-1180° C. for 20-40 minutes, and cooling to obtain a fired low-density...

Embodiment 1

[0027] A method for preparing low-density and high-strength petroleum ceramsite proppant by utilizing tuff, comprising the following steps:

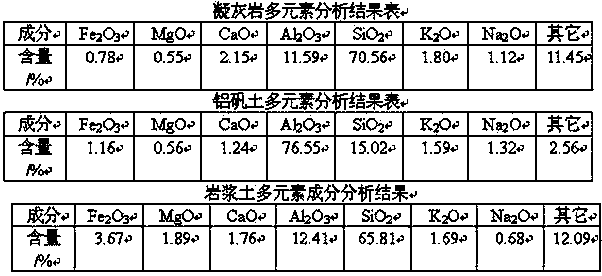

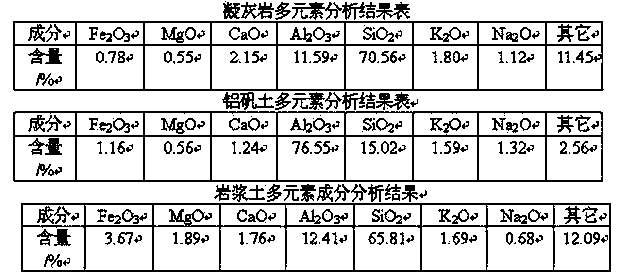

[0028] 1) Weigh 60% of tuff mineral powder, 30% of bauxite particles and 10% of magmatic soil particles according to the weight ratio, and dry them at 105°C for 4 hours, then mix them evenly to prepare Get the mix.

[0029] 2) Add the mixture and modified polystyrene particles in step 1) into a ball granulator to form balls, spray 0.5% industrial aluminum dihydrogen phosphate solution until the surface of the ball is wet, and then put the raw balls Dry at 130°C for 4 hours;

[0030] 3) The dried green balls in step 2) were calcined at 1180°C for 40 minutes, and then cooled to obtain calcined ceramsite petroleum proppant.

[0031] The particle size of the ceramsite prepared above is 0.66-0.84mm, and the bulk density of the ceramsite is 1.60g / cm 3 , the acid solubility is 4.0%, the turbidity is 98NTU; the closing pressure is 99MPa, the ...

Embodiment 2

[0033] A method for preparing low-density and high-strength petroleum ceramsite proppant by utilizing tuff, comprising the following steps:

[0034] 1) Weigh 55% of tuff mineral powder, 35% of bauxite particles and 10% of magmatic soil particles according to the weight ratio, and dry them at 130°C for 2 hours, and then mix them evenly to obtain a mixed material.

[0035] 2) Add the mixture and modified polystyrene particles in step 1) into a ball granulator to form balls. During the process of forming balls, spray industrial aluminum dihydrogen phosphate solution with a concentration of 0.1% until the surface of the balls is wet, and then put the raw balls Dry at 160°C for 4 hours;

[0036] 3) The green balls dried in step 2) were calcined at 1150°C for 30 minutes, and then cooled to obtain calcined ceramsite petroleum proppant.

[0037] The particle size of the ceramsite prepared above is 0.44-0.71mm, and the bulk density of the ceramsite is 1.5g / cm 3 , the acid solubility...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com